-

Posts

8,104 -

Joined

-

Last visited

-

Days Won

71

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by red750

-

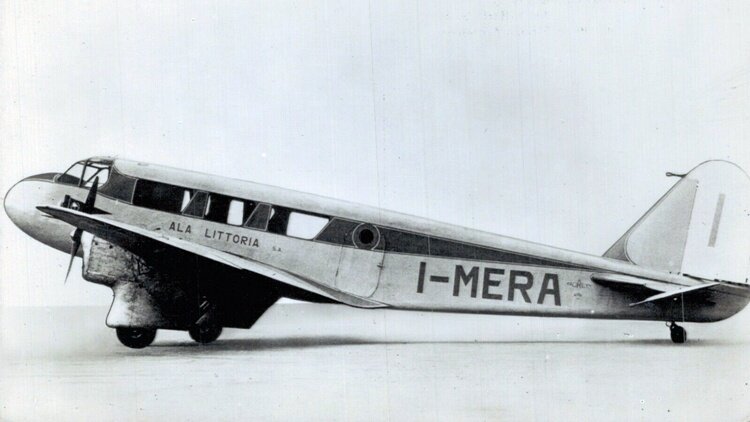

The Caproni Ca.308 Borea ("North Wind") was a small airliner built in Italy in the mid-1930s. The Ca.308 was a streamlined, low-wing cantilevered monoplane design of conventional configuration. Its undercarriage was not retractable. The mainwheels were fitted with spats. The prototype, designated Ca.306, was exhibited at the Milan Exhibition of 1935. The basic design of the Ca.308 subsequently served as the basis for a large family of military aircraft, beginning with the Caproni Ca.309. The Italian airline Ala Littoria ordered five examples. The Italian government ordered two aircraft for general-purpose use by its colonial administration in Libya. All these aircraft received the Ca.308 designation. Variants Ca 306 The prototype, exhibited at the Milan Exhibition of 1935. Ca 308 Borea Production aircraft, Seven built.

-

-

The Northrop F-15 Reporter (later RF-61) was an American unarmed photographic reconnaissance aircraft. Based on the Northrop P-61 Black Widow night fighter, it was the last piston-powered photo-reconnaissance aircraft designed and produced for the United States Air Force. Though produced in limited quantities, and with a relatively short service life, the F-15's aerial photographs of the Korean Peninsula would prove vital in 1950, when North Korea invaded the south. The F-15 Reporter was created when the guns were removed from the experimental XP-61E, the last fighter variant of the P-61 Black Widow. With less than six months flying time, the first XP-61E was taken back to the Northrop modification shop where it was converted into an unarmed photographic reconnaissance aircraft. All the guns were removed, and a new nose was fitted, capable of holding an assortment of aerial cameras. The aircraft, redesignated XF-15, flew for the first time on 3 July 1945, with Northrop test pilot L. A. "Slim" Parrett at the controls. A P-61C-1-NO (serial number 42-8335) was also modified to XF-15 standards as the XF-15A. Apart from the turbosupercharged R-2800-C engines, it was identical to the XF-15 and flew for the first time on 17 October 1945. For unknown reasons Northrop subcontracted the nose for the F-15A to the Hughes Tool Company of Culver City, California. The F-15A used the existing P-61C wings (without fighter brakes), engines and tail sections but with an entirely new, more streamlined fuselage housing a crew of two under a continuous bubble-canopy. As a result of continuing development trouble with the Howard Hughes-designed XF-11, the staff of the Army Air Force Headquarters determined an immediate need for 320 F-15 Reporters. Even before the first flight of the XF-15 an initial contract for 175 aircraft was signed in June 1945. Following testing it was determined that the F-15 Reporter possessed similar performance and flight characteristics to the troublesome XF-11, despite the Reporter being powered by less powerful engines, and using mostly pre-existing parts. This spelled the end to further development of the XF-11. The first production F-15A was accepted in September 1946. However, the contract was abruptly canceled in 1947, possibly because the performance of the aircraft was rapidly being overshadowed by jets, with the last of only 36 examples being accepted by the United States Army Air Forces in April of that year. The last F-15 to be produced (serial number 45-59335) was produced as an F-15A-5-NO, which differed from the Block-1 version mainly in having a new internal camera installation in the nose. It seems that this change had been contemplated for the last 20 F-15s as well, since some records indicate that these were all eventually re-designated as F-15A-5-NO. The F-15 had a revised center pod with pilot and camera operator seated in tandem under a single bubble canopy. The first XP-61E, from which the first XF-15 was converted, had the canopy hinged to the side, while all subsequent XF-15 and production F-15 employed a sliding canopy. The aircraft's six cameras were placed in an elongated nose, replacing the XP-61Es four guns. Production F-15A were powered by the same turbosupercharged R-2800-73 engines as the P-61C. The aircraft had a takeoff weight of 32,145 lb (14,580 kg) and a top speed of 440 mph (382 kn, 708 km/h) at 33,000 ft (10,058 m). In the end, only 36 of the 175 ordered F-15As were built, and all were constructed from aircraft originally contracted to be built as P-61C. Variants XF-15 The first prototype, converted from the first XP-61E. XF-15A The second prototype, converted from a P-61C (number 43-8335). F-15A Reporter Photoreconnaissance variant with a new center pod with pilot and camera operator seated in tandem under a single bubble canopy, and six cameras taking place of radar in the nose. Powered by the same turbosupercharged R-2800-73 engines as the P-61C. The aircraft had a takeoff weight of 32,145 lb (14,580 kg) and a top speed of 440 mph (382 kn, 708 km/h). Only 36 of the 175 ordered F-15As were built before the end of the war. After formation of the United States Air Force in 1947, F-15A was redesignated RF-61C. F-15As were responsible for most of the aerial maps of North Korea used at the start of the Korean War. RF-61C Reporter (Specifications below) USAF designation for the F-15C from 1948 onwards. Number built 36

-

The Curtiss-Wright CW-19 was a civil utility aircraft designed in the United States in the mid-1930s and built in small quantities in a number of variants including the CW-23 military trainer prototype. Originally conceived as the Curtiss-Robertson CR-2 Coupe shortly before the Curtiss-Wright merger and the dropping of the Curtiss-Robertson brand, it was an all-metal, low-wing cantilever monoplane of conventional configuration with fixed tailwheel undercarriage and side-by-side seating for two. A prominent feature on all versions other than the original CR-2 prototypes was the large "trouser"-style wheel spats. While the design was never perfected for the civil market it was originally intended for, a militarized version was soon developed that replaced the side-by-side cabin with tandem seating and added provision for guns and bombs. Twenty-six CW-19s of all types were produced. The first was a single CW-19L built in 1935, known as either "Coupe" or "Sparrow" in documents. It would be purchased by the US Government and assigned the registration number NS-69. The second aircraft built was a CW-19W, which featured a much more powerful 145 hp Warner Super Scarab in place of the Lambert engine. It was decided that this aircraft was not well-suited for private civil aviation, and was also discontinued after one prototype. The military-grade CW-19R saw a significant revision to the cockpit and canopy, removing the old "Coupe" design and replacing it with a tandem-seat sliding glass canopy. Powerplant options varied between the Wright R-760E2 and Wright R-975E3. A variety of armament options were also available, including a synchronized fuselage-mounted machine gun firing through the propeller arc, two gun pods mounted outboard of the landing gear, a flexible mount for the second aviator to use as a defensive turret, bombs, and an auxiliary fuel tank. Twenty two examples would be produced and would be the only version to be sold, with the majority going to South and Central American countries. The CW-A19R was an unarmed version of the CW-19R intended for the USAAC but without any success. It would also be offered on the civil market as the ATC A-629. A total of two CW-A19R would be completed—one company demonstrator for Curtiss-Wright and one sold to a private owner. A third was not completed and rebuilt as a CW-22. A CW-B19R was planned and advertised, based upon the CW-A19R but with a four or five-seat civilian cabin, but it was not built. Variants CR-2 - Curtiss-Robertson prototype with strut-braced wing and unfaired undercarriage (two built) Model 19L - prototype with cantilever wing, spatted undercarriage and Lambert R-266 engine (one built) Model 19W - prototype with Warner Super Scarab engine (one built) Model 19Q - Lycoming R-680-B2 Seaplane design (none built) Model 19R Fighter - militarized version with tandem seating, weapons mountings, and Wright J-6-7 engine (23 built) Model 19R Long Range Trainer - Extra center mounted 35 gallon aux tank pod. One fixed forward gun, one rear manned gun. Model 19R Light Bomber - Two .30 cal guns with two A-3 bomb racks. (563 lb) Model 19R Photo Reconnaissance - Two bottom mounted camera ports. Model 19R Attack (special) - single seat with wing mounted guns (none built) Model 19R Advanced Trainer - Pratt & Whitney R-760-E2 or R-975-E3 engine choices. Model 19R Seaplane - proposed 1936 variant of the 19Q (none built) Model A19R - military trainer offered to USAAC (three built, one later converted to CW-22)[1] Model B19R - projected civil version of Model A19R (none built) Model C19R - Amphibian standard trainer R-975-E3 (none built) Model C19R - Amphibian advanced trainer (none built) Model C19R - Amphibian fighter - One forward gun, one manned gun (none built) Model C19R - Amphibian photographic aircraft - Fairchild KB-3 camera mount Model C19Z - Standard Amphibian or Seaplane trainer - Pratt & Whitney Wasp SC-G CW-23 - advanced military trainer with Pratt & Whitney R-1340 engine and retractable undercarriage (one built)

-

The Curtiss-Wright AT-9 Jeep is an American twin-engined advanced trainer aircraft used by the United States during World War II to bridge the gap between single-engined trainers and twin-engined combat aircraft. The AT-9 had a low-wing cantilever monoplane configuration, retractable landing gear and was powered by two Lycoming R-680-9 radial engines. Curtiss-Wright anticipated the requirement for this type of "high-performance" aircraft and designed the Curtiss-Wright CW-25, a twin-engined trainer, which possessed the takeoff and landing characteristics of a light bomber. Using the same basic design as the larger Cessna AT-17 Bobcat, the new CW-25 was designed to simulate the demands of multi-engined operations. The design featured a small layout, grouping two Lycoming R-680-9 radial engines forward and using a retractable tailwheel landing gear to achieve the performance necessary to meet the requirements of an advanced trainer. The single CW-25 prototype acquired for evaluation had a welded steel-tube fuselage structure with the wings, fuselage and tail unit fabric-covered. The first prototype Model 25 flew in 1941 and the production version entered service as the AT-9 in 1942. Named the "Fledgling" by Curtiss-Wright, it commonly became known as the "Jeep" in the United States Army Air Forces (USAAF). The prototype CW-25 had a fabric-covered steel tube fuselage and fabric-covered wings and tail units, but production AT-9s were of stressed metal skin construction. The AT-9 was purposely designed to be less stable and proved to be difficult to fly or land, which made it particularly suitable for teaching new pilots to cope with the demanding flight characteristics of a new generation of high-performance, multi-engined aircraft such as the Martin B-26 Marauder and Lockheed P-38 Lightning. A total of 491 AT-9s were built before production ended and a new production run of 300 of the generally similar AT-9A commenced. Because of its difficult flying characteristics, the AT-9 was not offered for sale to civilians after the war, although many non-flying examples were given to ground schools for training purposes. Variants CW-25 Prototype with fabric covered fuselage and tail surfaces AT-9 Production aircraft with stressed-skin covering and two Lycoming R-680-9 radial engines, 491 built. AT-9A AT-9 with Lycoming R-680-11 radial engines and revised hydraulic system, 300 built before production ended in February 1943. Number built 792 (including prototype and AT-9A variant)

-

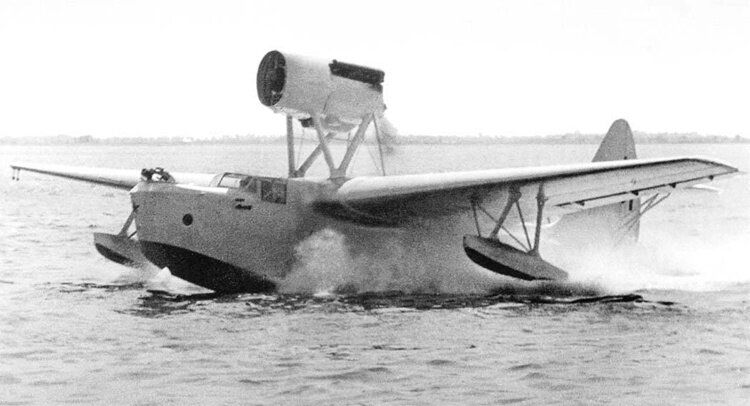

The Beriev MBR-2 was a Soviet multi-purpose (including reconnaissance) flying boat which entered service with the Soviet Navy in 1935. Out of 1,365 built, nine were used by foreign countries (including Finland and North Korea). In the Soviet Union, it sometimes carried the nickname of "Kорова" (cow) and "Амбар" (barn). The MBR-2 was designed by Georgy Mikhailovich Beriev and first flew in 1931, powered by an imported 373 kW (500 hp) BMW VI.Z engine. Production models, which arrived in 1934, used a licence-built version of this engine, the Mikulin M-17 of 508 kW (680 hp), and could be fitted with a fixed wheel or ski undercarriage. Beriev also designed a commercial airliner derivation, the MP-1, which entered airline service in 1934, and a freighter version, which followed in 1936. In 1935, an improved version was developed, the MBR-2bis, powered by the Mikulin AM-34N engine, and fitted with an enclosed cockpit, dorsal gun-turret and enlarged vertical tail. In this configuration, the machine remained in production until 1941. As with the MBR-2, the bis spawned a commercial derivative and the MP-1bis entered service in 1937. Variants MBR-2M-17 : Short-range maritime reconnaissance, bombing flying-boat, powered by a 508 kW (680 hp) Mikulin M-17B piston engine. MBR-2AM-34 or MBR-2bis : Improved version, powered by a Mikulin AM-34N engine. MBR-2M-103 : One MBR-2AM-34 was fitted with the more powerful M-103 engine. One prototype only. MP-1 : Civil version of the MBR-2M-17 flying-boat. It could carry six passengers in an enclosed cabin. MP-1bis : Civil version of the MBR-2AM-34 flying-boat. MP-1T : Freight transport conversion of MBR-2. Number built 1,365

-

The Morane-Saulnier MS.760 Paris is a French four-seat jet trainer and liaison aircraft designed and manufactured by Morane-Saulnier. The Paris was based upon an earlier proposed trainer aircraft, the MS.755 Fleuret. Following the failure of the French Air Force to select the Fleuret, Morane-Saulnier opted to develop the design into a liaison aircraft and compact business jet. The primary difference between the two designs was the altered seating arrangement, the original side-by-side seating two-seat cockpit was modified to allow for the addition of another row of two seats to accommodate passengers. The Paris retained the flight characteristics of the Fleuret along with the option for installing armaments, which maintained its potential for use as a military trainer as well for civil aviation. On 29 July 1954, the prototype performed the type's maiden flight. The primary operators of the Paris were the French air services, who used the type for liaison purposes between 1959 and 1997. During 1955, Morane-Saulnier and American aviation company Beech Aircraft formed a joint venture to market the Paris as the first business jet on the North American market, but the venture was dissolved a few years later due to a lack of customer interest. During the 1960s more advanced variants were developed such as the MS.760B Paris II and the six-seat MS.760C Paris III; the latter would not enter production however. While four-seat propeller planes are commonplace, jet-powered aircraft with this seating arrangement, such as the Grumman EA-6B Prowler combat aircraft, have remained comparatively rare. The Paris has its origins within an earlier jet trainer aircraft developed by French aircraft manufacturer Morane-Saulnier. During the early 1950s, the French Air Force sought a jet trainer suitable to the ab-initio training sector; in response, Morane-Saulnier produced their own submission, designated as the MS.755 Fleuret. However, the military competition was ultimately won by another bid, which was produced in large numbers as the Fouga Magister. Shortly after this failure, Morane-Saulnier decided to embark upon a re-design of the MS.755 to allow it to function as a four-seat liaison aircraft instead; accordingly, the new aircraft was later given the designation of MS.760 Paris. According to aerospace publication Flight International, the adaption from the earlier Fleuret to the Paris had been largely achieved via the elimination of the former's armament, the re-design of the cabin floor to remove the downward ejection hatch arrangement, and the repositioning of the cabin's rear bulkhead slightly aft.[4] To avoid a reduction of the aircraft's available fuel tankage as a result of the latter change, the tank was re-profiled in other areas to expand it. In spite of these changes, the Paris still retained the favourable flying characteristics and did not entirely foreclose its use as a trainer aircraft. The Paris differed from the majority of liaison aircraft then in service by its use of jet propulsion, instead of a turboprop or piston engine. According to M. Vichou, the head of the design department of Morane-Saulnier, the decision to adopt a pair of Turbomeca Marboré jet engines had been determined to be the superior option available; studies found that a single turboprop engine capable of providing at least 2,000 hp was necessary to produce a comparable performance, which would have resulted in the additional complications of appropriately accommodating a fairly large propeller in the design. Another alternative in using a pair of small turboprop engines was also less convenient than the Marboré engine, which could be positioned relatively low down in the airframe and in close proximity to the aircraft's centre-line. The all-up weight of the Paris, including a payload of four passengers and 30 kg (66 lb) of baggage, was 3,397 kg (7,470 lb) and its maximum flight speed was 650 km/h (400 mph). According to the manufacturer, it was able to ascend to an altitude of 7,000m (22,900ft) in 18 minutes; at this altitude and at maximum continuous thrust, the aircraft had a flight endurance of 2 hours 45 minutes and a maximum range of 930 miles. In terms of fuel, the main fuselage tank contained up to 1,000 litres (220 gal), while a further 250 litres (55 gal) could be accommodated in each tip-tank. A feature that was intended to be used in emergency situations was the provisioning of the tip-tanks with electrically actuated valves, which enabled the rapid dumping of any remaining fuel. Actuation of the flaps, dive-brake and undercarriage was provided using electric motors delivering power via flexible shafts and Lear electric motors. The nose of the Paris contained much of the avionics and electrical systems, including the radio, alternators, batteries and motors. Access to the engines was provided via a completely detachable tail unit; the wings could also be similarly detached without the necessity of removing the undercarriage. The sizable main canopy was a one-piece moulding, being 8 mm (0.3 lin) thick. For increased passenger comfort, the cabin was both fully pressurized and air-conditioned. On 29 July 1954, the prototype MS.760, registered F-WGVO (F-BGVO), took off on its maiden flight. Various features of its design, such as its T-shaped vertical stabilizer, low wing, and two Turbomeca Marboré II 400 kg turbojets internally mounted side by side within the aft fuselage, led to the aircraft being largely characterized for its inherent stability during flight. The French military emerged as a crucial early customer for the Paris, ordering a large batch of 50 aircraft to perform liaison duties for both the French Air Force and the French Navy, replacing older types such as the Nord Noralpha and Nord Norécrin. The securing of this order allowed Morane-Saulnier to proceed with quantity production of the type. On 27 February 1958, the first production aircraft performed its first flight. Early aircraft were provided with a total of four seats, two in the front and two in the back, and a retractable tricycle landing gear. Variants MS.760 Paris MS.760B Paris II MS.760C Paris III C-41: Brazilian Air Force designation of the MS.760A.

-

The Boeing C-97 Stratofreighter is a long-range heavy military cargo aircraft developed from the B-29 and B-50 bombers. Design began in 1942. The first of three prototype XC-97s flew on 9 November 1944 and the first of six service-test YC-97s flew on 11 March 1947. All nine were based on the 24ST alloy structure and Wright R-3350 engines of the B-29, but with a larger-diameter fuselage upper lobe (making a figure eight or "double-bubble" section) and they had the B-29 vertical tail with the gunner's position walled off. The first of three heavily revised YC-97A incorporating a wing with higher-strength 75ST alloy, taller vertical tail and larger Pratt & Whitney R-4360 engines of the B-50 bomber, flew on 28 January 1948 and was the basis of the sole YC-97B, all production C-97s, KC-97s and civilian Stratocruiser aircraft. Between 1947 and 1958, 888 C-97s in several versions were built, 811 being KC-97 tankers. C-97s served in the Berlin Airlift, the Korean War, and the Vietnam War. Some aircraft served as flying command posts for the Strategic Air Command, while others were modified for use in Aerospace Rescue and Recovery Squadrons (ARRS). The C-97 Stratofreighter was developed towards the end of World War II by fitting a second lobe on top of the fuselage and wings of the B-29 Superfortress with the tail, wing, and engine layout being nearly identical. The XC-97 and YC-97 can be distinguished from the Boeing 377 Stratocruiser and later C-97s by the shorter fin, and later ones by the flying boom and jet engines on the tanker models. The prototype XC-97 was powered by the same 2,200 hp (1,600 kW) Wright R-3350 engines as used in the B-29. The XC-97 took off for its first flight on November 9, 1944, just after the death of Boeing president Philip G. Johnson. On 9 January 1945, the first prototype, piloted by Major Curtin L. Reinhardt, flew from Seattle to Washington, D.C. in 6 hours 4 minutes, an average speed of 383 mph (616 km/h) with 20,000 lb (9,100 kg) of cargo. The tenth and all subsequent aircraft were fitted with the 3,500 hp (2,600 kW) Pratt & Whitney Wasp Major engines and taller fin and rudder of the B-50 Superfortress The C-97 had clamshell doors under its tail so that two retractable ramps could be used to drive in cargo, but it was not a tactical airlifter able to deliver to primitive forward bases. The doors could not be opened in flight, but could be removed to carry out air drops. The C-97 had a useful payload of 35,000 lb (16,000 kg), which could include two 2½-ton trucks, towed artillery, or light tracked vehicles such as the M56 Scorpion. The C-97 featured cabin pressurization, which made long flights more comfortable. The C-97 was developed into the civilian Boeing 377 Stratocruiser, a transoceanic airliner that could be fitted with sleeper cabins and featured a lower deck lounge. The first Stratocruiser flew on July 8, 1947. Only 56 were built. Number built 77 (plus 811 tankers) For operational history and details of the 25 variants, click here.

-

The CZAW Parrot, also called the CSA Parrot, is a Czech light-sport aircraft that was designed and produced by Czech Aircraft Works, now Czech Sport Aircraft of Prague. The aircraft first flew on 15 June 2005 and, while it was available, it was supplied as a complete ready-to-fly-aircraft. The Parrot was discontinued in May 2008, after three were completed and the design developed into the PS-10 Tourer. The Parrot was designed to comply with the US light-sport aircraft rules. It features a cantilever high-wing, a two-seats-in-side-by-side configuration enclosed cockpit, fixed tricycle landing gear with wheel pants and a single engine in tractor configuration. The Parrot is made from aluminum sheet. Its forward-swept 11.4 m (37.4 ft) span wing has an area of 9.5 m2 (102 sq ft). The forward sweep allows the cabin to be forward of the wing, providing pilot visibility in turns. Standard engines available were the 100 hp (75 kW) Rotax 912ULS and the 120 hp (89 kW) Jabiru 3300 four-stroke powerplants. The Parrot was first flown on 15 June 2005 and the prototype was immediately shipped to the United States to be displayed at AirVenture 2005. The design was added to the Federal Aviation Administration's list of approved special light-sport aircraft in January 2006. By May 2008 three Parrots had been completed and the aircraft was discontinued. The design was included in the intellectual property transferred from CZAW to CSA in 2009 and then redesigned with components from the PS-28 Cruiser and designated as the PS-10 Tourer. The PS-10 Tourer first flew on 6 December 2010 and was first publicly shown at the Aero show in Friedrichshafen in 2011. By December 2012 the PS-10 was not yet advertised for sale by CSA. Variants Parrot Base model with gross weight of 600 kg (1,323 lb). First flown 15 June 2005, discontinued May 2008 after three built. PS-10 Tourer Developmental evolution of the Parrot to include common engine cowling, nose gear and rudder assemblies with the PS-28 Cruiser, plus the addition of rear windows, larger elevator trim tab, removal of rudder horn and the empty weight was reduced. First flown 6 December 2010.

-

The General Aircraft GAL.42 Cygnet II was a 1930s British single-engined training or touring aircraft built by General Aircraft Limited at London Air Park, Hanworth. The Cygnet was designed at Slough by C.W. Aircraft Limited in 1936. It was the first all-metal stressed-skin light aircraft to be built and flown in the United Kingdom. The prototype, powered by a 90 hp (67 kW) Cirrus Minor engine, and registration G-AEMA was first flown in May 1937 at London Air Park, Hanworth. It had a fixed tailwheel undercarriage and low cantilever wing with rounded wingtips and a split trailing edge flap that ran under the fuselage. Two persons sat side by side in an enclosed cabin with a reverse-sloped windscreen. The metal airframe had a very slim semi-monocoque tailcone which carried the tailplane and a single, triangular fin and rudder. The prototype soon underwent a number of modifications, with the Cirrus Minor engine being replaced by a 130 hp (97 kW) de Havilland Gipsy Major engine, the cockpit canopy being revised to have a more conventional forward-sloped windscreen and the centre section of flap underneath the aircraft's fuselage removed. Thus modified, it was entered into the 1937 King's Cup Race on 10–11 September that year, finishing 13th. Airworthiness certification for the new type was slow, partially due to the Cygnet's extensive use of pop riveting, so that C.W. Aircraft made no sales of the Cygnet, while the company had also invested heavily in another design, the C.W. Swan, a six-seater to be powered by two de Havilland Gipsy Six engines. Overextended, C.W. aircraft became insolvent and was shut down in March 1938, with all rights for the Cygnet, together with the prototype, being sold to General Aircraft Ltd (GAL). For more details of the history of the Cygney, click here.

-

The Epic Victory was the second experimental jet designed by Epic Aircraft, a company that was based in Bend, Oregon. Epic Aircraft declared bankruptcy in 2009. Its assets were acquired by Aviation Industry Corporation of China and LT Builders Group; which as of July 2010 were in the process of restarting production of the Victory. The Victory is a single-engine very light jet that was intended to be powered by a single Pratt & Whitney Canada PW600. Epic used the Williams FJ33 engine for testing but planned to switch to the PW600 for final production. The aircraft seats 4 to 5, including the pilots, in a 2+2 or a 2+1+2 configuration. The aircraft took Epic six and a half months to design from concept to a flying prototype, with the first flight on 6 July 2007 from Roberts Field in Redmond, Oregon. The company had intended that the jet would be available for less than US$1 million. The aircraft was displayed at the Experimental Aircraft Association's AirVenture fly-in in 2007 at Oshkosh, Wisconsin, where the company began accepting down payments. The prototype's Federal Aviation Administration registration expired on 31 May 2017. It has not been renewed and the aircraft has been deregistered.

-

The Coupé-Aviation JC-01 is the first of a series of very similar designs of two seat, single engine sports aircraft, amateur built from plans in France from 1976. These provided a range of engine sizes and undercarriage layouts, but total production was small. The JC-01 and its variants were designed as conventional two-seat side by side light aircraft that could be built from plans by amateurs. The different models are chiefly distinguished by engine choice, though undercarriage configurations vary and there are slight alterations to the vertical surfaces. The J-01 and the J-2 have identical spans, wing areas and lengths, though the J-2, with a 90 hp rather than 65 hp engine and a tricycle rather than conventional undercarriage weighs more: empty, the J-01 weighs 330 kg (728 lb), the J-2 500 kg (1,103 lb). The J-2 has a constant chord, one piece low wing. Its inner panels have no dihedral but the outer ones are set at 4°. Both the main box spar and the rear spar have spruce booms and plywood webs. The leading edge is ply covered and fitted with fixed slots. The wing, including ailerons and flaps is Dacron covered overall. The empennage of the J-2 is conventional and cantilever, with the horizontal tail mounted on top of the fuselage; both fin and rudder are swept, the latter only slightly. The fixed surfaces are ply covered but control surfaces are fabric covered. The elevator has a trim tab. The fuselage of the J-2 is a three frame truss structure with a ply covered forward section and fabric covering aft. A 67 kW (90 hp) Continental C90 flat four engine in the nose drives a two-blade, fixed pitch propeller. Its fuel is stored in a tank immediately aft of the engine firewall. The cockpit, placed over the wing, seats two side by side under a large, rearward sliding canopy, with a space behind the seats which can take up to 20 kg (44 lbs) of baggage. The J-2 lands on fixed tricycle gear. The mainwheels have oleo-pneumatic damping and mechanical brakes; the nosewheel swivels. Plans were available to amateur builders for the construction of the JC-01 and its variants and about a dozen JC-01s were built. Two remained on the French civil aircraft register in 2010, together one example of each of the other variants making the total number of all variants built at least fifteen. Some builders included their own name and initials in the aircraft description, for example the Dessevres-Coupé JCD 01 and the Coupé-Brault JCFB 01. Variants Data from Jane's All the World's Aircraft 1984/85[1] and Fox-Papa JC-01 Original version with 48 kW (65 hp) Continental A65 engine and unswept rudder. Later the prototype was modified with a swept rudder. At least one was built with a Limbach L1700 engine. Tailwheel undercarriage. First flown 16 March 1976. JC-2 (Specifications below) Similar to JC-01 but with a 67 kW (90 hp) Continental C90, 50% heavier, swept vertical tail and tricycle undercarriage. First flown May 1981. JC-3 Lightened JC-01 with swept vertical tail and 51 kW (68 hp) Limbach L 1700 or 60 kW (80 hp) L 2000 engine. JC-200 "Refined" version of JC-2 with a 75 kW (100 hp) Rolls-Royce Continental O-200 engine, first flown 18 August 1989.

-

Not saying that your discussion is wrong or not worth pursuing. What I'm saying is that in respect to this particular accident, you are creating unproven assumptions to support your narrative. The students lack of experience may have resulted in him not having the peripheral awareness of the speed if the ground rising to meet him resulting in the bounce.

-

The Piper PA-47 "PiperJet" was a single-engined very light jet (VLJ) that was intended to be developed and built by Piper Aircraft. However, following a change of ownership at Piper, it was decided to redesign the aircraft as the PiperJet Altaire. Despite being technically successful, the Altaire project was canceled in October 2011 due to economic conditions. The aircraft is the first proposed single-engined civilian aircraft with a podded engine located on the tail. The PiperJet was announced in October 2006, as a competitor to the twin-engined Eclipse 500 and Cessna Citation Mustang. The aircraft's fuselage was the same cross section as the propeller-driven Piper PA-46 series, with a 4 feet (1.2 m) increase in length. It was to be capable of carrying up to 7 passengers and cruise at 360 knots (666.7 km/h), at a maximum altitude of 35,000 feet (10,668.0 m). Maximum range was expected to be 1,300 nautical miles (2,407.6 km), with a full-fuel payload of 800 pounds. Piper selected Williams International to supply its FJ44-3AP turbofan engine for the PiperJet. Due to the engine being mounted above the center of gravity, power was highly stabilizing (addition of power would push the nose down), which could have been disconcerting to pilots. Initially, Piper designers incorporated an automatic pitch trim system to coordinate horizontal stabilizer angle of incidence with power setting. This system was later replaced by a vectored thrust nozzle, developed by Williams International, which resulted in reduced weight and simplified manufacturing processes. A design feature of the aircraft was the use of a straight duct air intake design for the vertical stabilizer (tail) mounted engine, similar in engineering design concept to a McDonnell Douglas DC-10, rather than the s-duct arrangement of most trijet aircraft designs such as the Dassault Falcon 900. A selling price of US$2.199 million in 2006 dollars was initially set and as of February 19, 2007, Piper announced that it had received 180 pre-orders. An entry-into-service date of early 2010 was initially anticipated, later changed to 2011-12. In October 2009 the company indicated that it had delayed the delivery of the first customer aircraft to mid-2013 and had informed depositors. The PiperJet did not enter production and in October 2010 Piper announced it would instead develop an aircraft with a larger circular-section fuselage known as the Piper PiperJet Altaire. The 160 customers who had placed orders for the PiperJet retained their delivery positions with the new aircraft and at the same $2.2 million price.

-

https://www.msn.com/en-au/news/australia/air-canada-plane-starts-taxiing-towards-runway-with-baggage-handler-trapped-in-its-cargo-hold/ar-AA1U4KaP?ocid=winp2fptaskbarhover&cvid=dabb4b40a56046baea3acfee820c275e&ei=40

-

The Dyn'Aéro MCR4S is a four-seat development of the French two seat, single engine Dyn'Aéro MCR01. It first flew in early 2000 and is sold as a kit for homebuilding in several versions by SE Aviation of Pontarlier. The MCR4S is a four-seat development of the Dyn'Aéro MCR01 and retains many similarities. Both types are low wing, single engine monoplanes with T-tails. The major changes are an increase in fuselage length to accommodate an extra row of seats with generous windows and the replacement of the flaperons seen on the long span variants of the MCR01, which have wings of about the same span as those of the MCR4S, with slotted flaps. The wing and all control surfaces of the MCR4S have carbon fibre spars and ribs, to which preformed aluminium skins are glued. The wings have constant chord and carry 3° of dihedral. The ailerons are short, leaving the rest of the trailing edge of each wing divided between two double slotted, three position flaps. Winglets were introduced in 2001 and modified to have straight (in plan) trailing edges from 2002. The MCR4S has a T-tail with an all-moving tailplane. The fin is an integral part of the carbon fibre monocoque fuselage shell which also features a small ventral fin. The cabin seats up to four, depending on the variant, in two side-by-side rows. Entry is via the large, forward hinged, two piece canopy. Two large windows light the rear seats, the port side one doubling as an emergency exit. A variety of Rotax flat four engines may be fitted, driving a two or three blade propeller, which may have fixed or variable pitch. The MCRS4 has a tricycle undercarriage. The main wheels are mounted on short, vertical legs beneath the wings, as on the Club and ULC variants of the MCR01, with a track of 2.33 m (7 ft 8 in). All undercarriage wheels and legs are faired. The Dyn'Aéro MCR4S flew for the first time on 14 June 2000. The MCR4S structure has been used by EADS Defence & Security for its EADS Surveyor 2500 drone. The first public appearance of the MCR4S was at the International Air Rally held at Cranfield just nine days after the first flight. French certification was gained in June 2001 (DGAC) and the first customer, aircraft designer Pierre Robin, flew his aircraft shortly afterwards. UK certification (LAA), though sought, had not been achieved by 2009. In mid-2010, 90 MCR4Ss appeared on the civil aircraft registers of European countries excluding Russia. Variants Data from Jane's All the World's Aircraft 2011/12 Current (2010) versions are based on the MCRS4S-2002 specification. MCR4S evolution Powered by the new Rotax 915 iS engine and developed by SE Aviation in Pontarlier, France. MCR2S Ibis Two seat configuration with large baggage volume. Rotax 912 engine. Pickup Two seat, lightened to 290 kg (639 lb) empty, to produce a microlight aircraft with two seats, maximum internal capacity and performance. Rotax 912UL or ULS engines of 80 to 100 hp (60 to 75 kW). Three seat Three seat, powered by a 60 kW (80 hp) Rotax 912 UL or JPX 4TX75 engine. Four seat Four seat, powered by a 74 kW (99 hp) Rotax 912 UL-S engine. Four seat Performance (Specifications below) Four seat, powered by an 85 kW (113 hp) Rotax 914 UL engine. CITEC Powered by a Wilksch-120 90 kW (120 hp) two stroke, three cylinder diesel engine. Dyn'Aéro Twin-R Twin engine version, first flown March 2011.[1] MRC ULC Version lightened to 230 kg (507 lb) empty weight, with tricycle landing gear and powered by an 80 hp (60 kW) Rotax 912 UL or 100 hp (75 kW) Rotax 912 ULS powerplant. The aircraft has a cruise speed of 250 km/h (155 mph) with the 80 hp (60 kW) engine. MRC M Version of the MRC ULC with conventional landing gear and powered by an 80 hp (60 kW) Rotax 912 UL or 100 hp (75 kW) Rotax 912 ULS powerplant.

-

Copy and paste without checking. Conversions now corrected. That's what happens when you hurry.

-

John, there's a profile for that in the Electric Aircraft section of the showcase.

-

The Club ULM Rotor Ptenets-2 (Russian: Птенец-2, English: Chick or Fledgling) is a Russian ultralight aircraft, designed and produced by Club ULM Rotor of Kumertau, Bashkortostan. The aircraft is supplied complete and ready-to-fly. The aircraft was designed to comply with the Fédération Aéronautique Internationale microlight rules. It features a strut-braced high-wing, a two-seats-in-side-by-side configuration enclosed cockpit, fixed tricycle landing gear and a single engine in pusher configuration. The aircraft is made from aluminum tubing, with its flying surfaces covered in Dacron sailcloth. The fuselage is made from fibreglass. Its 10.2 m (33.5 ft) span wing has an area of 12.7 m2 (137 sq ft). The tail is supported by four tubes that allow space for the pusher propeller. Standard engines available are the 50 hp (37 kW) Rotax 503 and 64 hp (48 kW) Rotax 582 two-strokes and the 60 hp (45 kW) HKS 700E four-stroke powerplant.

-

The Ikarus C52 is a German ultralight aircraft, designed and produced by Comco Ikarus, introduced at the Aero show held in Friedrichshafen in 2011. The aircraft is supplied as a complete ready-to-fly-aircraft. An evolution of the Ikarus C42, the C52 was designed to comply with the Fédération Aéronautique Internationale microlight rules. It not only updates the older design, but offers more comforts. The C-52 is not intended to replace the C42 in production, but instead to act as a higher-end complementary model. Like the C42, it features a strut-braced high-wing, a two-seats-in-side-by-side configuration enclosed open cockpit, fixed tricycle landing gear and a single engine in tractor configuration. The aircraft differs from the earlier C42 primarily in that the landing gear is a cantilever design, the tail is constructed of carbon fibre and the engine mount was redesigned. Its 9.45 m (31.0 ft) span wing employs V-struts with jury struts and has an area of 12.5 m2 (135 sq ft). Standard engines available are the 80 hp (60 kW) Rotax 912UL and the 100 hp (75 kW) Rotax 912ULS four-stroke powerplants.

-

The Coavio DF 2000 is a single-engine, high-wing all-metal ultralight aircraft with side-by-side seating for two. Built in Italy, production began in 2004. The DF 2000 was designed to provide a fast, robust, comfortable, low-cost side-by-side two-seat ultralight with a short take-off run. It has a conventional layout not unlike that of, for example, the Cessna 152, with a high wing, swept vertical tail and tricycle undercarriage. Structurally, it is mostly built from aluminium alloy, reinforced with TIG-welded 4130 steel tubing in the cockpit area. The wing has constant chord and is braced on each side by a single, broad streamlined strut from the bottom of the fuselage. The shallow, turned-up wing tips are formed from composites. Inboard flaps are fitted. The cockpit area, under the wings and fitted with dual controls, is accessed by upward-hinged doors with deep glazing. Aft, the fuselage becomes more slender, though the swept fin has a long fillet. The rudder has a trim tab and the low-set, parallel-chord tailplane carries a balanced elevator. The tricycle undercarriage has main wheels which are cantilever spring-mounted from the lower fuselage and a steerable nose wheel. All wheels are usually spatted. The DF 2000 family uses several engine/propeller combinations, mostly from the Rotax 912 series of 80 to 100 hp (60 to 75 kW) flat-4s but also the 85 hp (63 kW) Jabiru 2200 and 120 hp (89 kW) Jabiru 3300 powerplants. The DF 2000 first flew in about 2001 and went into production three years later. 54 DF 2000 series aircraft have been built up to 2021. Variants Details from the manufacturer. Spartan Lightest DF 2000, 60 kW (80 hp) Rotax 912 UL engine, 2-blade wooden propeller. Mechanical trim control and flap actuation. DF 2000 Light (or Base) Standard version, as Spartan but painted and with oil pressure gauge. DF 2000 Plus 75 kW (100 hp) Rotax 912 ULS engine, composite 3-bladed propeller with ground-adjustable pitch. Electrical elevator trim control and flap actuation, flap hinge fairing, partial cabin ventilation and additional instrumentation. Wheel spats and landing light. DF 2000 Top (Specifications below) As Plus with a bigger oil cooler, radio and further instrumentation, upholstered seats and cabin panelling. Landing lights, radio and cockpit heater standard. Two-colour external paintwork. Flight-adjustable pitch propeller an option. DA Evolution de Luxe version with either 75 kW (100 hp) Rotax 912 ULS or 64 kW (86 hp) Jabiru 2200[2] engine. As Top, but with full cabin ventilation, improved seating and electrical aileron trim control. Improved external lighting. Three colour external paintwork and bigger spinner.

-

The Douglas AC-47 ("Puff, the Magic Dragon")

-

Wikipedia description of Cotton duck. Cotton duck (from Dutch: doek, meaning "cloth"), also simply duck, sometimes duck cloth or duck canvas, is a heavy, plain woven cotton fabric. Duck canvas is more tightly woven than plain canvas. There is also linen duck, which is less often used. Cotton duck is used in a wide range of applications, from sneakers to painting canvases to tents to sandbags. Historically, white untwilled cotton or linen fabric uniforms of this name were worn by British and French soldiers serving in the tropics. Duck fabric is woven with two yarns together in the warp and a single yarn in the weft. Duct tape or duck tape is cloth- or scrim-backed pressure-sensitive tape, often coated with polyethylene. A variety of constructions exist using different backings and adhesives, and the term "duct tape" has been genericized to refer to all of them. A variation is heat-resistant foil tape useful for sealing heating and cooling ducts, produced because standard duct tape fails when used on heating ducts.

-

UPS cargo plane crash. Louisville Kentucky

red750 replied to danny_galaga's topic in Aircraft Incidents and Accidents

There was an episode of Air Crash Investigation on Channel 7 this afternoon which reported on a DC-10 crash almost identical to the above accident, with the engine separating from the left wing just after takeoff with the plane rolling to the left, crashing, killing all 270 on board. The rear mounting lug appeared to be damaged when the engine was being reinstalled after a previous repair, causing a fatigue crack in the lug. The breakaway engine damaged the hydraulic lines in the leading edge of the left wing, preventing the outer slats on the wing from operating, preventing that wing from creating the correct lift.