-

Posts

8,104 -

Joined

-

Last visited

-

Days Won

71

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by red750

-

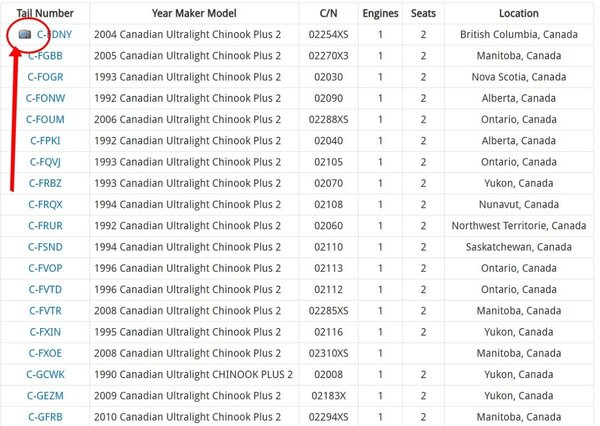

The thing that intrigues me is that Canadians don't seem to have cameras or smart phones. airport-data.com have pages of Canadian build aircraft listed (registrations, construction numbers, etc.) but no photos. They are possibly high-winged floatplanes, but you wouldn't know, you don't know what they look like. Often a web search for the aircraft doesn't bring up a photo. And all weight shift aircraft look pretty much alike. All these aircraft and only one photograph -

-

In October I set myself a goal to have 2000 profiles completed by the end of the year. This gets increasingly more complicated. Wikipedia lists thousands of aircraft, but only has details pages of a fraction of them and many are variants of the same aircraft. Also, a large number listed as separate aircraft are actually licence built versions of other aircraft. I have completed 84 profiles since the beginning of December, including 15 on Dec 31, and posted the 2000th at 11:58 New Year's Eve. I think I'll wait now till a few more models are released.

-

The Göppingen Gö 4 or Goevier is a German sailplane of the late 1930s used for training pilots. Its most notable features include side-by-side seating and dual controls, making the plane ideal for use as a trainer. It boasted average performance, compared to other gliders of the day, and was advertised as making the process of learning to fly sailplanes easier. The Goevier (or Gövier; Gö 4 read aloud in German) was designed as a modern trainer with side-by-side seating for easy communication between student and tutor, with performance comparable to that of the intermediate single seat trainers of the day such as the Grunau Baby and Göppingen Gö 1 Wolf. Its glide angle of 19:1 was rather better than that of both these aircraft (17:1). It is a cantilever mid-wing monoplane. The wing has a single spar and a plywood covered D-box nose; aft of the spar the wing is fabric covered. The centre section is of constant chord and the outer panels tapered, with sweep on both edges. Here the trailing edge carries long span, broad chord ailerons with curved edges which extend aft of the centre section trailing edge, giving a roughly elliptical plan. The side-by-side seat arrangement inevitably makes the front fuselage wider (945 mm; 37.4 in externally) than that of a single or tandem seat aircraft, though as the seats are just ahead of the main spar and the mid-wing placed at shoulder height, the interior opening into the wing roots provides extra working space. These roots were early examples of the use of plastics in gliders, formed from hessian soaked in phenolic resins and shaped in a mould. The cockpit is enclosed with glazing and its roof line runs smoothly into that of the upper fuselage above the wing. The fuselage, plywood covered all over, tapers to the tail where the cross-section is shield shaped. The ply covered tailplane is mounted on a small step above the fuselage; together with the fabric covered elevators the horizontal tail is trapezoidal in plan with rounded tips. The fin and rudder were altered several times during the development of the Goevier, initially with both broad and with the fin extending forward to the leading edge of the tailplane, but on all production models it is narrow and upright, carrying several slightly different rudder designs. From 1941 the rudder was aerodynamically balanced. The Goevier lands on a monowheel undercarriage, with a skid reaching forward from it to the nose and with a small tail skid. The Goevier V-1 made its first flight on 30 November 1937, piloted by Heinz Kensche. It was often towed by a Klemm Kl 25. Production began at Göppingen the following October. Variants Data from The Göppingen Gö 4 (GOEVIER), Der berühmtesten Segelfluzeuge, and Sailplanes 1920-1945 Goevier I Prototype V-1. Length 6.74 m (22 ft 1 in), span 14.80 m (48 ft 6.7 in). Broad fin and rudder. Goevier II Production model before and during World War II. About 100, possibly more, built before February 1941. Another 6 were built by Fokker immediately post-war. Length 7.26 m (23 ft 10 in), span 14.73 m (48 ft 4 in). Narrower fin and rudder. From 1941 with horn-balanced and slightly less rounded rudder on same fin. Goevier III (aka Hirth-Hütter Goevier III) – Dipl.-Ing. Wolf Hirth/Wolfgang Hütter.Post-war production model, prototype V-2. About 20 built. As later Goevier II but length 6.24 m (20 ft 5.6 in). Hirth Hi-20 MoSe Powered, self launching version completed in 1941. Retractable propeller.

-

The Staudacher S600F is a new design (2003) based on the earlier S300 and S600 aerobatic airplanes. The goal is to create an unlimited capable aerobatic monoplane with enhanced cross country utility. The S600F has two seats and dual controls. The front cockpit can be equipped as complete as the rear cockpit. The design incorporates a very streamlined composite shell over most of the tubular fuselage. Attached flow should be achieved over a much greater area than earlier planes for greater speed and less yaw in turbulence. Appearance is also much better. In addition to the traditional baggage area in the turtle deck, the S600F has a second baggage area just aft of the fire wall, between and above the passengers legs. A lot of weight can be carried here as it is very close to the C.G. All fuel is carried in the wings with a fuselage mounted, gravity fed header tank. There is no fuel selector, just an on-off valve. A roll bar, just aft of the passenger, will provide increased safety. Tail feathers are, as always, fabric covered and wire braced.

-

The Beck-Mahoney Sorceress is a racing staggerwing biplane originally designed by the father and son team of Lee and Seldon Mahoney with later improvements accomplished by pilot Don Beck. The aircraft is notable as being the first biplane to exceed 200 mph (320 km/h) on a race pylon course and also held the distinction of being the most successful racing biplane in history, until Tom Aberle's Phantom, which has won eight Reno Gold championships since its introduction in 2004. It was donated to the Smithsonian National Air and Space Museum after its last race, where it is currently housed in the Steven F. Udvar-Hazy Center in Chantilly, Virginia. A reverse-stagger biplane, Sorceress represents the state of the art at the time of its design and remains one of the great design classics of air-racing within the United States. Lee Mahoney, the designer, had experience in airframe construction with composite materials, metal-to-composite bonding technologies, and computational fluid dynamics, applying his experience to design Sorceress, and achieve success with several noteworthy design features, including: Use of engine exhaust air flow forms a Coandă effect-bonded laminar flow over the fuselage, increasing rudder efficiency by several orders of magnitude. Mahoney had originally designed the fuselage so that a fin would not be necessary - the fuselage would have ended with a rudder, but his partners however preferred a more conventional treatment, giving Sorceress one of the smallest conventional fins of any racing biplane to date. The aerofoil sections of the wings are designed as mirror image 'vanes' of symmetrical section - they interfere with each other's flow in a manner which provides very high efficiency in turns, whereas one vane-set/wing begins to lose efficiency, the other gains more, allowing for extremely high lift in turns with minimal loss of velocity Sorceress gains a great deal from composite bonding, with one of the first airframes to demonstrate almost perfect streamlining combined with very great strength; the wing interplane struts are for show only, Sorceress being capable of flight without them, but racing rules require them. For details of results and records. click here.

-

The CAG Toxo is a Spanish two-seat ultralight cabin monoplane designed and built by Construcciones Aeronauticas de Galicia for amateur construction. The prototype Toxo ultralight first flew in 1999 and was a low-wing cantilever monoplane with fixed tricycle landing gear. The Toxo can be powered typically by a 120 hp (89 kW) Jabiru 3300 or a Rotax 914S engine. The cabin has two seats side-by-side with dual controls, each with a centerline-hinged upward-opening door. Variants Toxo Variant approved as an ultralight Toxo II Variant approved in the VLA category.

-

The Canadair CL-44 was a Canadian turboprop airliner and cargo aircraft based on the Bristol Britannia that was developed and produced by Canadair in the late 1950s and early 1960s. Although innovative, only a small number of the aircraft were produced for the Royal Canadian Air Force (RCAF) (as the CC-106 Yukon), and for commercial operators worldwide. The aircraft is named after the Canadian territory of Yukon. In the 1950s, Canadair acquired a licence to build the Bristol Britannia airliner. Their first use of it was to build the heavily modified Canadair CL-28 Argus patrol aircraft (RCAF designation CP-107) that combined the Britannia's wings and tail sections with a new fuselage and engines. The resulting aircraft had lower speed and service ceiling, but it had two bomb bays and greatly extended loiter times. The RCAF required a replacement for its C-54GM North Star, itself an extensive redesign of the Douglas C-54 Skymaster. Among many changes, the proposed new aircraft was powered by Merlin engines. Canadair began work on a long range transport primarily intended to provide personnel and logistics support for Canadian Forces in Europe. In January 1957 Canadair received a contract for eight aircraft, later increased to 12. The RCAF designation for the new design was CC-106 Yukon, while the company's civilian variant was known as the CL-44-6. In company parlance the CL-44 was simply "the Forty-Four." The RCAF specified the CL-44 to be equipped with Bristol Orion engines. When the British Ministry of Supply canceled the Orion program, the RCAF revised the specifications to substitute the Rolls-Royce Tyne 11. The CL-44 fuselage was lengthened, making it 12 ft 4 in (3.75 m) longer than the Britannia 300 with two large cargo doors added on the port side on some aircraft, while the cabin was pressurised to maintain a cabin altitude of 2,400 m at 9,000 m (30,000 ft). The design used modified CL-28 wings and controls. The Yukon could accommodate 134 passengers and a crew of nine. In the casualty evacuation role, it could take 80 patients and a crew of 11. The rollout of the Yukon was a near-disaster because the prototype could not be pushed out of the hangar since the vertical fin could not clear the hangar doors.] The first flight took place 15 November 1959 at Cartierville Airport. During test flights many problems were encountered, from complete electrical failure to engines shaking loose and almost falling off. Rolls-Royce had problems delivering engines, resulting in the sarcastically-named "Yukon gliders" being parked outside Canadair as late as 1961. For operational history and details of 7 variants, click here.

-

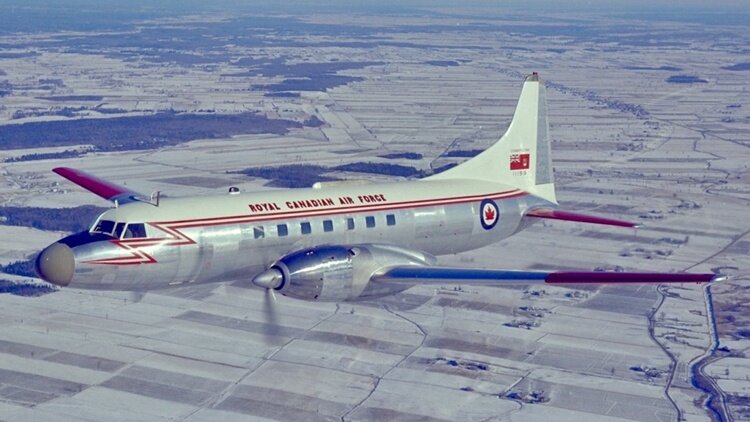

The Canadair CL-66 was a turboprop version of the civilian Convair CV-440 Metropolitan. The CC-109 Cosmopolitan or "Cosmo" in RCAF service became the standard VIP aircraft as well as replacing the Douglas Dakota and the North American B-25 Mitchell in light transport duties. After a lengthy career stretching into the 1990s, the CC-109 was replaced by the CC-142 Dash 8 and CC-144 Challenger. With the close of production of the Convair CV-440 in San Diego, Canadair acquired the rights to the design along with the jigs, tooling and even three unsold 440s. With the availability of a Napier Eland turboprop conversion, the re-engined CV-440s became the CV-540, an all-cargo variant. In 1958, the RCAF wanted to replace their aging C-47 Dakotas with a turbine-powered aircraft. Their choice was the Vickers Viscount, but the Canadian government decided against this aircraft. Instead, Canadair offered a series of CV-540 variants powered by Napier Eland turboprops. The project was given the number CL-66 and three versions were considered. The CL-66A was to be a 48/64 passenger aircraft. The CL-66B designed to be a cargo/passenger configuration with a payload of 14200 lb. The CL-66C used the Convair-built CV-440s, having only their new engines fitted at Canadair. The first CL-66 to fly was a "C" version with its first flight in February 1959; the CL-66B had its first flight in January 1960. No "A" versions were built. Canadair was not able to get contracts from any major airline for the CL-66. It was too expensive and other similar types had better performance. The two aircraft, both of them CL-66Cs, that had been used for extensive sales demonstrations, were sold to the local carrier Quebecair. The RCAF took ten aircraft, mainly Bs. The Eland not only proved to be unreliable, but also did not deliver the expected power, consequently, the RCAF instituted an engine upgrade in 1966–1967, installing Allison 501-D36 engines. After eight airframes had been re-engined, the company phased out further development work on the type, "orphaning" the remaining final two Eland examples, which were subsequently scrapped. No. 412 Squadron at CFB Ottawa (S), or "Uplands" flew the "Cosmo", from 1960 to 1994 as VIP transport. The Cosmopolitan aircraft were also deployed to Europe for Canadian NATO contingent support as well as to the US in support of Canadian NORAD operations.

-

The Breda Ba.88 Lince ("Lynx") was a ground-attack aircraft used by the Italian Regia Aeronautica during World War II. Its streamlined design and retractable undercarriage were advanced for the time, and after its debut in 1937 the aircraft established several world speed records. When military equipment was installed on production examples, problems of instability developed and the aeroplane's general performance deteriorated. Eventually its operational career was cut short, and the remaining Ba.88 airframes were used as fixed installations on airfields to mislead enemy reconnaissance. It represented, perhaps, the most remarkable failure of any operational aircraft to see service in World War II. The Breda Ba.88 was designed to fulfill a 1936 requirement by the Regia Aeronautica for a heavy fighter bomber capable of a maximum speed of 530 km/h (330 mph)—faster than any other aircraft existing or being planned at the time)—armament of 20 mm cannons and range of 2,000 km (1,200 mi). It first flew in October 1936. The project was derived from the aborted Ba.75 also designed by Giuseppe Panzeri and Antonio Parano. Technical description The Ba.88 was an all-metal, twin-engine, two-crew monoplane, with a high-mounted wing. It employed a "concentric" fuselage design, with a framework of steel tubes and a metallic skin covering which was both streamlined (having a very small fuselage cross-section) and strong. However, this internal load-bearing structure was very complex and of outdated design, as monocoque designs were starting to be developed elsewhere. The internal struts resulted in excessive weight compounded by manufacturing delays. The narrow confines of the fuselage would require the Ba.88 to carry bombs in a semi-external structure - to the detriment of the aircraft's aerodynamics. The all-metal wings had two longerons, and housed the engine nacelles, undercarriage main elements, and the majority of the 12 self-sealing fuel tanks (the only protection in the aircraft), providing 1,586 L (419 US gal) total capacity. All three undercarriage units were retractable, which was unusual for the time. The aircraft was powered by two Piaggio P.XI air-cooled radial engines. They were of the same type as used in other projects such as the Re.2000, and drove two three-blade, constant-speed 3.2 m (10.4 ft) diameter Breda propellers. The engine nacelles also carried the two main undercarriage units. The aircraft had a twin tail to provide the dorsal 7.7 mm (0.303 in) Breda-SAFAT machine gun with a better field of fire. The aircraft had three nose-mounted 12.7 mm (0.5 in) Breda-SAFAT machine guns with 400, 450 and 400 rounds of ammunition respectively. A 7.7 mm (0.303 in) Breda machine gun (500 rounds) with a high arc of fire, was fitted in the rear cockpit and controlled by a complex motorised electrical system. A modern "San Giorgio" reflector gunsight was fitted, and there was also provision to mount a 20 mm cannon instead of the central machine gun in the nose. The payload was three bombs of 50 kg (110 lb) or three of 100 kg (220 lb) or two of 250 kg (550 lb), or a Nardi dispenser for 119 2 kg (4.4 lb) bomblets. Together these weapons gave the Ba.88 impressive armament for its time. The forward pilot's cockpit was fully instrumented, with an airspeed indicator capable of reading to 560 km/h (350 mph), gyroscope and an altimeter (useful to 8,000 m (26,000 ft). For more details of development, operational history and 4 variants, click here.

-

The Boulton Paul Balliol and Sea Balliol are monoplane advanced trainer aircraft designed and produced by the British aircraft manufacturer Boulton Paul Aircraft. On 17 May 1948, it became the world's first single-engined turboprop aircraft to fly. The Balliol was operated primarily by both the Royal Air Force (RAF) and the Royal Navy Fleet Air Arm (FAA). Developed during the late 1940s, the Balliol was designed to fulfil Air Ministry Specification T.7/45, replacing the wartime North American Harvard trainer. Unlike previous trainer aircraft, which were powered by piston engines, it was specified for the aircraft to use newly developed turboprop propulsion instead. On 30 May 1947, the Balliol performed its maiden flight; the first preproduction aircraft would fly during the following year. Production examples were powered by the Rolls-Royce Merlin engine, while various prototypes and pre-production aircraft featured alternative powerplants such as the Rolls-Royce Dart and Armstrong Siddeley Mamba turboprop engines. The Balliol entered service with the RAF in 1950 and proved to be a relatively trouble-free trainer. However, a shift in attitudes towards turbojet-powered trainer aircraft would see orders being curtailed for the type by 1952. Despite this, a navalised version of the aircraft, the Sea Balliol, was also introduced for deck landing training. The type also saw some use in other capacities, such as for experimental flights. Only a single export customer, the Royal Ceylon Air Force, would procure the type. Origins During March 1945, the Air Ministry issued Specification T.7/45, which sought a new advanced trainer to succeed the Royal Air Force's (RAF) fleet of North American Harvards. Amongst the requirements specified was the use of the newly developed turboprop engine, as it was felt that the new generation of advanced trainers would better prepare pilots for flying jet-powered combat aircraft such as the newly emerged Gloster Meteor fighter aircraft. As a fallback measure in case of difficulties being encountered with engine development programmes, the envisioned trainer was also to readily accommodate a more conventional Bristol Perseus radial engine as well. A further stipulation by the ministry was the fitting of a three-seat cockpit in a configuration roughly akin to the contemporary Percival Prentice basic trainer. The pilot and instructor were sat in a side-by-side arrangement, while a second student could be accommodated in a third seat to the rear, positioned as to enable them to closely observe the pilot and the instructions being issued. The trainer was to be configured to perform various forms of training, being suitable for both day and night operations, featuring both guns and bombs for armament training, a glider-towing capability, and a general design that would be compatible with navalisation measures, such as a strengthened undercarriage and the fitting of arrestor gear. Within a month of the specification's issuing, Boulton Paul Aircraft had opted to produce multiple proposals in response, as large orders had been anticipated. Boulton Paul's P.108 proposal, which would become the Balliol, was that of a conventional low-wing monoplane, featuring retractable main undercarriage and a fixed tailwheel. Towards the end of August 1945, Boulton Paul received an order from the Air Ministry, calling for the production of a batch of four prototypes, which were to be powered by the Rolls-Royce Dart turboprop engine. During August 1946, this was followed by a larger order for 20 pre-production aircraft, with ten each to be powered by the Dart and the Armstrong Siddeley Mamba turboprop, with delays to development of the Dart meaning that the prototypes would now be fitted by the Mamba. Competing proposals from other manufacturers were also submitted, including Avro's Athena in particular. For more details of development, design, operational history and 4 variants, click here.

-

The Blackburn Shark was a carrier-borne torpedo bomber designed and built by the British aviation manufacturer Blackburn Aircraft. It was originally known as the Blackburn T.S.R., standing for "torpedo-spotter-reconnaissance", in reference to its intended roles. The Shark was the last of Blackburn's biplane torpedo bombers. The prototype Shark performed its maiden flight on 24 August 1933, the first production aircraft was introduced to service during the following year. It was operated by the Fleet Air Arm, Royal Canadian Air Force, Portuguese Navy, and the British Air Observers' School. During the leadup to the 1939 war began the more capable Blackburn Shark was more complex to build so increased production went to its earlier rival the Fairey Swordfish. Despite this, numerous aircraft continued to be operated during the Second World War, largely being confined to secondary roles away from the front lines, such as training and target tug duties. Despite this, Sharks were repeatedly deployed in frontline roles during events such as the Dunkirk Evacuation and the Japanese invasion of British Malaya. During 1945, the final Sharks were withdrawn from service. The Blackburn T.9 Shark has its origins within the early 1930s as a private venture by the company. Originally known as the Blackburn T.S.R., standing for torpedo-spotter-reconnaissance, it was designed in conformance with Air Ministry Specification S.15/33, which sought a combined torpedo-(naval artillery) spotter-reconnaissance aircraft for the Fleet Air Arm (FAA). Blackburn was not the only company that opted to pursue this requirement; Fairey Aviation designed the TSR 1, a forerunner to the highly successful Fairey Swordfish that was active during the Second World War. The T.S.R. represented a substantial departure from Blackburn's previous naval aircraft designs, as the design team had opted to eliminate almost all use of streamlined bracing wires in favour of slanted struts. Despite this change, the wings were still foldable to ease stowage; a hydraulic wing-locking mechanism was incorporated to speed up folding/unfolding actions. Further measures to improve deck handling included the adoption of a tracking tail and pneumatic wheel brakes. The design process had been aided by operational experienced gained from the Blackburn Baffin. Features, such as the camber-changing flaps and fuselage construction, were derived from earlier prototypes. Initially, the design of the T.S.R featured open cockpits, which were heated by an exhaust pipe muff.[4] It had a crew of three, with the pilot seated in the first cockpit while the observer/wireless operator and gunner sharing the second cockpit, although longer range missions would sometimes be flown with only a crew of two. A prone position for bombing missions was also provisioned for, which included a watertight hatch and a hinged course-setting bomb sight. The bomb fusing controls were placed within reach of both the pilot and observer positions; ammunition was stowed in ten ammunition pans within the gunner's cockpit. Armament consisted of one fixed, forward-firing .303 in (7.7 mm) Vickers machine gun, plus a .303 in (7.7 mm) Vickers K machine gun or Lewis Gun mounted on a Scarff ring in the rear cockpit, with provision for a 1,500 lb (680 kg) torpedo or equivalent bombload carried externally. The fuselage was strengthened to withstand catapult launches and divided into watertight compartments. Structural elements included stainless steel tubular spars and light alloy ribs; similar materials were used for the entire tail section save for the Alclad-plated fin.[6] The majority of the flying surfaces had fabric coverings; the wing tips were detachable as to allow their easy replacement if damaged. The main fuel tanks were not integral to the structure; instead, two detachable tanks composed of duralumin were carried in separate watertight compartments forward of the pilot, housing up to 182.5 gallons of fuel. The aircraft had a range of 623 miles normally, but this could be extended to 1,130 miles via the use of a cylindrical tank, attached to the torpedo crutches, that was capable of holding up to 150 gallons of additional fuel. For details of operational history and 6 variants, click here.

-

The Bratukhin Omega (also known as the 2MG) was an early Soviet helicopter, the first product of a new Soviet design bureau, OKB-3 that was created from within TsAGI specifically to develop rotary-wing aircraft. Bratukhin's design was a transverse rotor aircraft, with each rotor carried on a long outrigger truss. The Omega's rotors were each powered by a separate engine carried in a nacelle also at the end of the truss. Captive trials commenced in August 1941 and revealed severe problems with engine vibration and overheating. Before these could be addressed, however, OKB-3 was evacuated ahead of the German advance into the Soviet Union. Flight testing recommenced in mid-1942, with the Omega still flying on a tether until early the next year. Free-flight trials confirmed the design as basically sound, so although the engine difficulties were never fully resolved, Bratukhin was convinced that further development along the same general lines would prove fruitful. Development of the Omega helicopter was incremental with progressively more powerful engines, stronger structure and more reliable dynamic components, such as gearboxes and transmission shafts. The ultimate iteration of the Omega was the Bratukhin B-11 which was used to compare characteristics of the products of the three competing helicopter designers. Completed in 1948 this was probably the most successful of the breed up to that time but still exhibited some of the short-comings of the configuration; mismatch between fixed wing and rotor and reliability of the complex dynamic components. The lateral twin-rotor system was not put to rest, however, and was resurrected in the Kamov Ka-22 and the Mil V-12. Variants Bratukhin 2MG (2 Motor Gelikopter – twin engined helicopter) - Alternative designation for the 'Omega'. Bratukhin Omega II - The Omega with more powerful engines in streamlined pods, with fan-assisted cooling, and stiffer, more reliable dynamic components. Bratukhin G-2 - Alternative designation for "Omega II". Bratukhin G-3 - 2 x prototype artillery spotter helicopters, "Omega II" with imported 450 hp Pratt & Whitney Wasp Junior engines. One prototype 'AK' delivered to VVS for pilot training. Bratukhin G-4 - The first Soviet helicopter powered by purpose-designed engines with a cooling fan and front mounted gearbox with outputs for rotor drive and inter-connection shaft as well as a centrifugal clutch and improved rotor, two prototypes built. Bratukhin B-5 - The first Helicopter named after Bratukhin was a scaled-up "G-4" with more powerful engines and a new airframe of light alloy stressed skin with a lifting aerofoil wing set at zero incidence, completed in 1947 but only limited test flying due to excessive wing flexure. Bratukhin B-9 - An ambulance derivative of the 'B-5' with a larger fuselage housing four stretchers in two layers with an attendant. The wing was changed to a symmetrical section set at positive incidence. One example completed in 1947 but never flown due to the wing flexure problems identified by flight testing of the 'B-5'. Bratukhin B-10 - With a new fuselage this slightly enlarged version of the "B-9" introduced bracing struts from the fuselage through the wings at the main spar and up to the rotor head. An observation cupola was fitted at the extreme nose, above the pilots cockpit, and a gunners position was provided at the aft end of the fuselage. Power was supplied by fully boosted AI-26GRF engines. A twin-finned variable incidence tail unit was also introduced. The new fuselage allowed the "B-10" to fulfill all the envisaged roles without building separate versions. One example was built in 1947 and underwent successful flight testing. Later the "B-10" was flown with single ShKAS machine guns in the nose and tail positions. Bratukhin B-11 - To provide data for comparison with Yakovlev and Mil helicopters two examples of the "B-11" were authorized and underwent flight testing to measure their performance from April 1948. Single-engined flight, auto-rotation and a marked reduction in vibration were all demonstrated. Problems identified included; a persistent hydraulic leak and rotor stalling due to lack of lift from the fixed wing at high speeds. Many modifications were proposed before the first prototype was destroyed, and the pilots killed, after the right hand rotor shed a blade in flight. A general disillusionment with helicopters in general and superior handling and performance from single rotor designs led to termination of the twin lateral rotor Bratukhin helicopters. Bratukhin AK - Ten AK (Artilleriskii Korrektirovshchik – artillery correction) production G-3 helicopters ordered but manufacture and/or delivery is uncertain. Bratukhin VNP (Vozdushnii Nabludatyelnii Punkt - aerial observation point) - Alternative designation for "B-10".

-

The Brantly 305 is an American five-seat light helicopter of the 1960s. It is an enlarged version of the Brantly B-2 which was produced by the Brantly Helicopter Corporation. The five-seater Model 305 helicopter is based on the smaller two-seat Brantly B-2 that was designed by Newby O. Brantly. The helicopter is powered by a Lycoming IVO-540 flat six piston engine.[1] The enlarged cabin has room for five passengers, two side-by-side forward-facing seats and a bench seat at the rear for three passengers. The Model 305 first flew during January 1964 and FAA type approval was received 29 July 1965. 45 were built during the mid 60's by Brantly and Brantly-Hynes produced an improved version in 1985 of which 4 were built. The Brantly 305 suffered from a ground resonance problems.[citation needed] Hynes developed a more powerful and streamline version in 1993, none were produced.

-

The Blume Bl.500, Bl.502, and Bl.503 were a family of four-seat light aircraft designed in West Germany by Dr Walter Blume in the late 1950s. Derived from his Arado Ar 79, the basic design shared by all models was that of a conventional low-wing cantilever monoplane with retractable tricycle undercarriage and all-metal construction. The Bl.500 prototype was built for Blume at the Focke-Wulf plant and was powered by a Lycoming O-320 engine of 112 kW (150 hp). This led to a modified version, the Bl.502 that achieved German type certification and was offered for sale alongside the generally similar Bl.503 with a more powerful engine. However, no orders were forthcoming and Blume abandoned the project. The final example of the design, the Blume Bl.503 was still active in 1965. Variants Bl.500 prototype Bl.502 intended production version with Lycoming O-320 Bl.503 proposed production version with Lycoming O-360. A single example was completed.

-

The Dornier 228 is a twin-turboprop STOL utility aircraft, designed and first manufactured by Dornier GmbH (later DASA Dornier, Fairchild-Dornier) from 1981 until 1998. 245 were built in Oberpfaffenhofen, Germany. In 1983, Hindustan Aeronautics Limited (HAL) bought a production licence and manufactured another 125 aircraft in Kanpur, Uttar Pradesh, India. In July 2017, 63 aircraft were still in airline service. In 2009, RUAG started building a Dornier 228 New Generation in Germany. The fuselage, wings and tail unit are manufactured by HAL in Kanpur, India, and transported to Oberpfaffenhofen, where RUAG Aviation carries out aircraft final assembly. The Dornier 228NG uses the same airframe with improved technologies and performances, such as a new five-blade propeller, glass cockpit and longer range. The first delivery was made in September 2010 to a Japanese operator. In 2020, RUAG sold the Dornier 228 program to General Atomics subsidiary General Atomics AeroTec Systems. Subsequently production was resumed and the newest version called Do228 NXT is currently being developed and manufactured. For details of development, design and more, click here.

-

The Bloch MB.160 was a fourteen-seat French airliner intended for use in the French African colonies. Three were built and two entered service with Régie Air-Afrique at the start of World War II. Developments included the Bloch MB.162 bomber which was too late for service and the Sud-Est SE.161 Languedoc, one hundred of which were built post-war. The first flight of the Bloch MB.160 was on 18 June 1937, piloted by André Curvale at Villacoublay, Marcel Bloch's base. On 20 August, now named the Lieutenant-Génin, it was one of thirteen aircraft from three countries (France, Italy and the UK) to take part in a 6,190 km (3,850 mi) race from France to Syria and back, flying from Istres to Damascus and returning to Paris. Nine finished, with Italian Savoia-Marchetti SM.79s in the first three places; the Bloch, piloted by Captain François, was seventh, taking 17h 38 min at an average speed of 273 km/h (170 mph). On 17 October the MB.160 set a new world speed record for an aircraft carrying a 5,000 kg (11,000 lb) useful load over 2,000 km (1,200 mi), averaging 307.455 km/h (191.044 mph; 166.012 kn). By March 1938 it had completed testing at Marignane and had returned to Villacoublay for minor aileron alterations and for some internal revision. By this time a second example was under way. As late as November 1938 one Bloch MB.160 was back for further modifications to the wing. In July 1939 the first of two delivered to Air-Afrique (only the second and third Bloch 160s appeared on the French civil register) had completed its exploration flights, with passengers, in Algeria. Though only three MB.160s were built a development of it, the MB.161, was the pre-war prototype of the Sud-Est SE.161 Languedoc. Its first flight was in September 1939; one hundred of them were built post-war. The Languedoc had a 7% greater span, twin end plate fins and a slightly shorter fuselage. 1,150 hp (860 kW) Gnome-Rhône 14N44/45 radial engines replaced the Hispano-Suizas in the prototype but production aircraft had 890 kW (1,200 hp) Pratt & Whitney R-1830-92 Twin Wasp radials. The MB.162 was the final MB.160 variant, initially developed for long range flights but flown as a bomber. Like the MB.161, it had twin fins and Gnome-Rhône 14N engines. Only one was built, making its first flight on 1 June 1940. For details of design and variants, click here.

-

The Breda-Zappata B.Z.308 was an Italian four-engined airliner produced by Breda. it was conceived by the engineer Filippo Zappata in 1942, still in time war, with all the problems connected to the priorities of the moment, so much so that the September 8, 1943 only the fuselage of the prototype was built. In the period 1944-45 the work was blocked first by the Germans and, at the end of the conflict, by the Allies, whose Allied Armistice Commission prohibited the continuation of any aeronautical project until the beginning of 1946.Vincenzo Melecca . The B.Z.308 was a four-engined civil transport developed in the late 1940s for operation over both European and transatlantic routes. A large low-wing monoplane of all-metal construction, it was powered by four Bristol Centaurus radial engines driving five-bladed propellers. It had a large tailplane with endplate fins and rudders, and had retractable landing gear. The fuselage, oval in cross-section, accommodated a flight crew of five and 55 passengers in two cabins; a high-density model was planned with seats for 80. In early 1946 the work resumed, also slowed down by British resistance to delivering the needed engines, so the aircraft was completed in June 1946 and the first flight took place on August 27, 1948. V.Meleca Construction began during 1946, under aircraft designer Filippo Zappata at Breda's Sesto San Giovanni works. The Allied Commission halted the work, which was not resumed until January 1947. Further delays in the delivery of Bristol Centaurus engines delayed the first flight, which was on 27 August 1948, piloted by Mario Stoppani. Although flight testing went well, the project was abandoned as a result of financial problems, and anticipated competition from American airliners in the postwar market. Breda subsequently stopped producing aircraft entirely. The prototype B.Z.308 was acquired by the Italian Air Force in 1949 as a transport aircraft (MM61802). Despite orders in 1950 from India, Argentina and Persia, only the prototype was built, allegedly also due to pressure from the allies for Italy to refrain from competing in civilian aircraft manufacture after the war. On 27 August 1948 the Bz 308 made its maiden flight in front of civil and military authorities, politicians and the Italian President. The prototype, which passed to the Italian Air Force in 1950, was used to fly between Rome and Mogadishu until 21 February 1954, when it was damaged beyond repair by a collision with a cement truck, and was abandoned in a field in Somalia before being broken up. It was also the first Italian transatlantic aircraft, and the first aircraft to fly into the new Malpensa airport in 1948. The aircraft has a brief appearance in the 1953 movie Roman Holiday.

-

The Apollo Fox is a Hungarian ultralight and light-sport aircraft produced by Apollo Ultralight Aircraft, of Eger. The aircraft is supplied complete ready-to-fly. The Apollo Fox was derived from the Aeropro Eurofox, which itself was a metric adaptation of the Denney Kitfox. The Kitfox in turn is a derivative of the Avid Flyer. The Apollo Fox was adapted to comply with the Fédération Aéronautique Internationale microlight rules and US light-sport aircraft rules. It features a strut-braced high-wing, a two-seats-in-side-by-side configuration enclosed cockpit, fixed tricycle landing gear or optionally conventional landing gear and a single engine in tractor configuration. The aircraft fuselage is made from welded steel tubing, while the wing is built with aluminum spars and ribs. The fuselage and flying surfaces are covered in doped aircraft fabric. Its 9.15 m (30.0 ft) span wing is supported by V-struts and jury struts and features Junkers-style ailerons. Standard engines available are the 64 hp (48 kW) Rotax 582 two-stroke, the 80 hp (60 kW) Rotax 912UL and the 100 hp (75 kW) Rotax 912ULS four-stroke powerplant. The cabin width is 110 cm (43 in). The aircraft's wings fold for storage or ground transportation and can be folded by one person in ten minutes. In 2003 a 100 hp (75 kW) Rotax 912ULS-equipped Fox was flown by Andor Kántás and Csongor Lathky from Sármellék, Hungary to Sydney, Australia, a distance of 25,000 km (15,534 mi).

-

The Aquila A 210 is a two-seat reinforced plastic light aircraft produced in Germany from 2002. It remains in production in 2022 as the updated A211. The marketing name A 210 is usually used to refer to Aquila's light side by side two seat aircraft, though its official engineering and certification name is Aquila AT01. Design work started in 1997 and the first flight was made in March 2000. The A 210 is entirely built from carbon and glass fibre reinforced plastics (CFRP and GFRP). CRFP is used for the more highly stressed members, spars, frames and stringers, GFRP for shells and control surfaces, the latter with GFRP/polyurethane sandwich construction. The low wing has straight tapered inboard sections with increasing sweep outboard and winglets at the tips on production examples. It has a laminar flow section and 4.5° of dihedral. The ailerons are balanced and the inboard single slotted Fowler flaps have two positions. The A 210 is powered by a Rotax 912 flat four engine driving a two blade propeller. The cabin has uninterrupted transparencies fore and aft, with a slender fuselage behind. The canopy is forward hinged. The tailplane is set just above the fuselage and the fin is swept. A small ventral fin doubles as a tail bumper. The A 210 has a fixed tricycle undercarriage. Its mainwheels are fitted with hydraulic brakes and mounted on spring steel legs from the fuselage. The nosewheel has rubber suspension and is steerable; speed fairings are fitted on all wheels. German certification was achieved in 2001 and deliveries began the following year. It gained US certification in 2003. Early sales were to clubs, mostly as training aircraft. Most have been sold in Europe and overall 120 have been built by late 2010. 110 appear as Aquila AT01 on the civil aircraft registrations of European countries excluding Russia in 2010. After the acquisition of the company by a Turkish investor, one plane was gifted to Gendarmerie General Command. Variants Aquila A 210 Original model Aquila A 211 Conventional instrument panel Aquila A 211GX Glass cockpit model

-

The Arctic Aircraft Arctic Tern (named after the bird) is a bush plane that was produced in small numbers in Alaska in the 1970s and 1980s. It is a strengthened and modernised version of the Interstate Cadet of the 1940s. It is a high-wing braced monoplane with fixed tailwheel undercarriage. It has two seats in tandem, with the rear seat removable for added cargo carriage. It is also provided with a cargo loading door in the fuselage side to facilitate loading bulky items. Optional fittings included floats or skis in place of the wheeled undercarriage, and a ventral pod to carry extra cargo or fuel. In 2007, the Interstate Aircraft company was planning a revised and updated Arctic Tern, with US FAA certification expected in the first half of the year.

-

The CAB GY-20 Minicab is a two-seat light aircraft designed by Yves Gardan and built in France by Construction Aeronautiques du Bearn (CAB) in the years immediately following World War II. CAB was formed in 1948 by Yves Gardan, Max Lapoerte and M. Dubouts. The Minicab is a conventional, low-wing cantilever monoplane with fixed tailwheel undercarriage, powered by a Continental A65 engine. Its design was a scaled-down version of the aircraft that Yves Gardan had designed for SIPA, the SIPA S.90. The pilot and passenger sit side by side and access to the cockpit is via a one-piece perspex canopy that hinges forwards. Gardan's intention was to produce a low-cost, easy-to-fly, easy-to-maintain aircraft with the possibility of homebuilding. The prototype Minicab first flew at Pau-Idron on 1 February 1949 with Max Fischl at the controls. CAB manufactured a total of about 65 Minicabs when production ended in 1955. The rights for the plans were then acquired by Arthur Ord-Hume in the United Kingdom who anglicised the drawings and made various minor improvements for home-builders. A large number were completed by amateur builders in the United Kingdom, France and other countries around the world. There is about 20 Minicabs currently active in the United Kingdom, many of which were built (or rebuilt) to the JB.01 standard, developed by M. Jean Barritault, usually with a Continental C90 engine. Falconar sold plans for a tricycle gear homebuilt model named the Minihawk. Another development is the K&S or Squarecraft Cavalier which is a redesigned Minicab in several versions with plans translated from French to English and modified by Stan Mcleod. The plans were marketed by K&S Aircraft of Calgary, Alberta and later MacFam. Variants GY-20 Minicab CAB first production model. GY-201 Minicab refined version with increased fuel capacity, reduced wingspan, strengthened undercarriage, split flaps, and castoring tailwheel. CAB final production model and also principal homebuilt version. Barritault JB.01 Minicab built to the modified design of Jean Barritault. Falconar Hawk Minicabs built to plans supplied by Falconar Falconar MiniHawk plans-built design from Falconar with tricycle undercarriage. MacFam Cavalier (K&S or Squarecraft Cavalier) Redesigned in several versions principally with tricycle and swept tail surfaces, and strengthened for a more powerful engine.

-

The Berkut 360 is a tandem-seating, two-seat homebuilt canard aircraft with pusher configuration and retractable landing gear, built primarily of carbon fiber and fiberglass. The Berkut 360 is featured in the 2010 movie Kill Speed (Fast Glass). The prototype Berkut was designed and built by Dave H. Ronneberg as part of a business partnership between Ronneberg and Donald S. Murphy, called Experimental Aviation, that lasted from 1989 to 1992. In 1992 the partnership dissolved and Ronneberg, incorporating as Experimental Aviation, Inc., brought the aircraft to market as a kit, while Murphy wanted to shelve the project entirely. A subsequent series of lawsuits between the two resulted in bankruptcy for Ronneberg and Murphy as individuals and for Experimental Aviation as a corporation. The kit was resurrected in 1996 by Richard Riley and Renaissance Composites, with Ronneberg working as a consultant. In January 2001, under pressure from Ronneberg, Renaissance sold the assets to Vicki Cruse, an American aerobatic pilot,[failed verification – see discussion] who then formed Berkut Engineering and Design, Inc. That company withdrew the aircraft from the market in 2002. Ronneberg continued with the project, which is now directed at UAV markets. A deal was struck in 2003 to sell the project to Republic Aerospace, but the deal fell through. Cruse was no longer involved with day-to-day operations, but maintained ownership until her death on August 22, 2009, when the aircraft she was flying — a borrowed Zivko Edge 540 — crashed in Buckinghamshire, England, during a qualifying flight for the World Aerobatic Championships. Through the various incarnations, approximately 75 kits were sold and 20 airplanes completed. The Berkut is derived from the Rutan Long-EZ, with the primary differences being retractable main landing gear, dual canopies, and molded fuselage, strakes, and wing spar. Like the Long EZ, the Berkut carries two people in a tandem seating arrangement. The front seat occupant has access to all instrumentation and controls. The rear seat, normally holding the passenger, is equipped with a side stick and throttle, but no rudder pedals, brakes, or instruments. Aerodynamic optimizations to the original Long-EZ airframe were made to increase performance and interior space. The fuselage was stretched and the nose, canard, instrument panel and pilot moved forward one foot (300 mm), to allow a heavier engine to be used in the rear. The main wing trailing edge was straightened, removing a small bend in the trailing edge of the Long EZ wing. The lower winglet was removed and the aileron size increased in both chord and span, significantly increasing roll rate. Early Berkuts used wings and canard that were structurally similar to the Long-EZ and used solid blue 2 lb/cu. ft. density Dow STYROFOAM PI cores cut to shape with a hot-wire foam cutter, but with carbon fiber reinforced polymer skins instead of fiberglass. The fuselage and winglets remained fiberglass. Later versions (kits produced after spring 1999) used fully molded carbon fiber canards and wings with high density, 5 lb/cu. ft. 1/4" thick PVC or SAN foam cores, leaving only minor fairings and tip surfaces to be carved from foam. The Berkut has always used the Roncz 1145MS canard airfoil, which is more tolerant of insect and rain contamination than the GU 25-5(11)8 airfoil originally used on the Long-EZ. The Berkut used a retractable main (rear) landing gear system designed by Shirl Dickey for his E-Racer homebuilt. Originally, Berkut used gear parts produced by Dickey, but over time they were repeatedly re-engineered and strengthened. Later kits had gear components produced entirely in-house. Like the earlier Vari-Eze and Long EZ, the Berkut kneels with its nose gear retracted to prevent the aircraft from tipping over backwards when parked without a pilot in the front seat. Some early Berkuts utilized hydraulic nose-gear extension systems, but most have used an electro-mechanical jack-screw. With the electric system, the pilot and passenger can climb into the cockpit, then extend the nose gear, raising the airplane with occupants inside. While the Long-EZ, originally designed for the Lycoming O-235 108-118 hp engine, was closer in the design of the Berkut, the latter was designed from the outset for the larger Lycoming IO-360 180 hp engine. The aircraft was later adapted, with a different engine mount, cowls and battery location, to accept the 260 hp Lycoming IO-540, which most builders chose. With the O-540, some have reportedly reached speeds of 300 mph in level flight. Variants Berkut 360 Original configuration, retractable gear, Lycoming 4-cylinder 360-cubic-inch, fuel-injected, 180 hp engine. Berkut FG360 Fixed-gear version of the 360. (Offered but never built, except as a UAV by Geneva Aerospace ) Berkut 540 Lycoming 6-cylinder, 540-cubic-inch, 260 hp engine upgrade. Changes consisted of larger cowls, a different engine mount, custom engine mount ears, stiffer engine isolators, a custom sump modification and different cooling baffles. Berkut FG540 Fixed-gear version of the 540. (offered, but never built) Mobius A modified Berkut with a single canopy and automated flight equipment where the second seat would be located, for UAV research and development with a 20-hour endurance. Two aircraft have been built with a third one in development. N442LT is the first tail number. N497LT is the second. Berkut Jet A Berkut using a modified GE T-58 turbine engine, built by Jerrold Jorritsma, registration number N3255U. Crashed in Loveland, Colorado on May 9, 2010. Berkez or Berk-EZ Heavily modified Rutan Long-EZ homebuilt with Berkut components.

-

The Vidor Champion V is an Italian homebuilt aircraft that was designed by Giuseppe Vidor, first flying on 10 June 1995. The aircraft is supplied in the form of plans for amateur construction. It is also known as the Asso Aerei V Champion. The Champion V was developed into the Alpi Pioneer 300, with the addition of composite skin. The Champion V features a cantilever low-wing, a two-seats-in-side-by-side configuration enclosed cockpit under a bubble canopy, fixed or optionally retractable tricycle landing gear and a single engine in tractor configuration. The aircraft is made from wood, with its flying surfaces covered in doped aircraft fabric. Its 8.321 m (27.3 ft) span wing mounts flaps and has a wing area of 11 m2 (120 sq ft). The wings are removable in about 15 minutes for ground transport or storage. The cabin width is 42 in (110 cm). The acceptable power range is 75 to 100 hp (56 to 75 kW) and the standard engine used is the 75 hp (56 kW) Volkswagen air-cooled engine four cylinder, air-cooled, four stroke automotive conversion powerplant. The Champion V has a typical empty weight of 272 kg (600 lb) and a gross weight of 480 kg (1,058.2 lb), giving a useful load of 208 kg (459 lb). With full fuel of 49 litres (11 imp gal; 13 US gal) the payload for the pilot, passenger and baggage is 173 kg (381 lb). The manufacturer estimates the construction time from the supplied kit as 1500 hours. By 1998 the company reported that 15 kits had been sold and three aircraft were completed and flying. In January 2014 one example was registered in the United States with the Federal Aviation Administration.

-

The Shenyang J-15 (Chinese: 歼-15; pinyin: Jiān-Shíwǔ), also known as Feisha (Chinese: 飞鲨; pinyin: fēi shā; lit. 'Flying Shark'; NATO reporting name: Flanker-X2, Flanker-K) is a Chinese all-weather, twin-engine, carrier-based 4.5 generation multirole fighter aircraft developed by the Shenyang Aircraft Corporation (SAC) and the 601 Institute, specifically for the People's Liberation Army Naval Air Force (PLANAF) to serve on People's Liberation Army Navy's (PLAN) aircraft carriers. The aircraft entered active service with the PLAN in 2013. An improved variant, named J-15T, incorporating CATOBAR launch capability, modern fifth-generation avionics, entered active service in the South China Sea in October 2024. In 2001, the T-10K-3, an unfinished prototype of the Su-33, was acquired by SAC from Ukraine[8] and is claimed to have been studied extensively and reverse-engineered, with development on the J-15 beginning immediately afterward. China had sought to purchase Su-33s from Russia on several occasions—an unsuccessful offer was made as late as March 2009—but negotiations collapsed in 2006 after it was discovered that China had developed a modified version of the Sukhoi Su-27SK, designated the Shenyang J-11B, in violation of intellectual property agreements. However, according to Chinese sources, the reason China withdrew from talks was that Russia wanted large payments to re-open Su-33 production lines and insisted on a Chinese purchase of at least 50 Su-33s, about which China was reluctant, as it believed the aircraft would become outdated in a few years. China hence decided on an indigenous variant instead of continuing to assemble the J-11, the licensed Chinese version of Su-27. The J-15 program was officially started in 2006 with the codename Flying Shark. The program goal was to develop a naval-capable fighter aircraft from the Shenyang J-11, with technologies reverse-engineered from T-10K-3, a Soviet Su-33 prototype that had been acquired from Ukraine. The first J-15 prototype made its maiden flight on August 31, 2009, believed to have been powered by Russian-supplied Saturn AL-31 turbofan engines. Video and still images of the flight were released in July 2010, showing the same basic airframe design as the Su-33. On May 7, 2010, the aircraft conducted its first takeoff from a simulated ski-jump on land. On November 25, 2012, the aircraft successfully performed its first takeoff and landing on Liaoning, China's first operational aircraft carrier. The twin-seat variant, J-15S, made its maiden flight on November 4, 2012. After conclusion of the flight-test phase, in 2013 the first 24 J-15 aircraft were delivered to the Naval Aviation’s Carrier Fighter Group. For more details of development, design, operational history, and 5 variants, click here.