-

Posts

8,054 -

Joined

-

Last visited

-

Days Won

71

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by red750

-

The Vidor Champion V is an Italian homebuilt aircraft that was designed by Giuseppe Vidor, first flying on 10 June 1995. The aircraft is supplied in the form of plans for amateur construction. It is also known as the Asso Aerei V Champion. The Champion V was developed into the Alpi Pioneer 300, with the addition of composite skin. The Champion V features a cantilever low-wing, a two-seats-in-side-by-side configuration enclosed cockpit under a bubble canopy, fixed or optionally retractable tricycle landing gear and a single engine in tractor configuration. The aircraft is made from wood, with its flying surfaces covered in doped aircraft fabric. Its 8.321 m (27.3 ft) span wing mounts flaps and has a wing area of 11 m2 (120 sq ft). The wings are removable in about 15 minutes for ground transport or storage. The cabin width is 42 in (110 cm). The acceptable power range is 75 to 100 hp (56 to 75 kW) and the standard engine used is the 75 hp (56 kW) Volkswagen air-cooled engine four cylinder, air-cooled, four stroke automotive conversion powerplant. The Champion V has a typical empty weight of 272 kg (600 lb) and a gross weight of 480 kg (1,058.2 lb), giving a useful load of 208 kg (459 lb). With full fuel of 49 litres (11 imp gal; 13 US gal) the payload for the pilot, passenger and baggage is 173 kg (381 lb). The manufacturer estimates the construction time from the supplied kit as 1500 hours. By 1998 the company reported that 15 kits had been sold and three aircraft were completed and flying. In January 2014 one example was registered in the United States with the Federal Aviation Administration.

-

The Shenyang J-15 (Chinese: 歼-15; pinyin: Jiān-Shíwǔ), also known as Feisha (Chinese: 飞鲨; pinyin: fēi shā; lit. 'Flying Shark'; NATO reporting name: Flanker-X2, Flanker-K) is a Chinese all-weather, twin-engine, carrier-based 4.5 generation multirole fighter aircraft developed by the Shenyang Aircraft Corporation (SAC) and the 601 Institute, specifically for the People's Liberation Army Naval Air Force (PLANAF) to serve on People's Liberation Army Navy's (PLAN) aircraft carriers. The aircraft entered active service with the PLAN in 2013. An improved variant, named J-15T, incorporating CATOBAR launch capability, modern fifth-generation avionics, entered active service in the South China Sea in October 2024. In 2001, the T-10K-3, an unfinished prototype of the Su-33, was acquired by SAC from Ukraine[8] and is claimed to have been studied extensively and reverse-engineered, with development on the J-15 beginning immediately afterward. China had sought to purchase Su-33s from Russia on several occasions—an unsuccessful offer was made as late as March 2009—but negotiations collapsed in 2006 after it was discovered that China had developed a modified version of the Sukhoi Su-27SK, designated the Shenyang J-11B, in violation of intellectual property agreements. However, according to Chinese sources, the reason China withdrew from talks was that Russia wanted large payments to re-open Su-33 production lines and insisted on a Chinese purchase of at least 50 Su-33s, about which China was reluctant, as it believed the aircraft would become outdated in a few years. China hence decided on an indigenous variant instead of continuing to assemble the J-11, the licensed Chinese version of Su-27. The J-15 program was officially started in 2006 with the codename Flying Shark. The program goal was to develop a naval-capable fighter aircraft from the Shenyang J-11, with technologies reverse-engineered from T-10K-3, a Soviet Su-33 prototype that had been acquired from Ukraine. The first J-15 prototype made its maiden flight on August 31, 2009, believed to have been powered by Russian-supplied Saturn AL-31 turbofan engines. Video and still images of the flight were released in July 2010, showing the same basic airframe design as the Su-33. On May 7, 2010, the aircraft conducted its first takeoff from a simulated ski-jump on land. On November 25, 2012, the aircraft successfully performed its first takeoff and landing on Liaoning, China's first operational aircraft carrier. The twin-seat variant, J-15S, made its maiden flight on November 4, 2012. After conclusion of the flight-test phase, in 2013 the first 24 J-15 aircraft were delivered to the Naval Aviation’s Carrier Fighter Group. For more details of development, design, operational history, and 5 variants, click here.

-

The ANF Les Mureaux 110 and its derivatives were a family of all-metal military reconnaissance aircraft developed and produced by the French aircraft manufacturer ANF Les Mureaux. It was designed in response to a requirement issued by the French air ministry. Introduced to service during the 1930s, in excess of two hundred aircraft were procured for the French Air Force to equip not just its frontline units but also to replace aircraft such as the Potez 25s from reserve units. Multiple variants were operated by the service, perhaps most noteworthy was the conversion of 40 aircraft to serve as dedicated night fighters. The family was in widespread usage at the start of the Second World War, and thus saw intense combat during the Battle of France. All remaining aircraft were scrapped in the aftermath of the armistice with Germany. The ANF Les Mureaux 110 originated with a French air ministry requirement for an aircraft to replace the Breguet 19 in Armée de l'Air service in the "R2" two-seat reconnaissance role. ANF Les Mureaux opted to produce a clean-sheet response to this requirement. It was during this design work that the firm developed a new technique for metal construction, it was promptly incorporated into the new long distance observation aircraft, which was later designated 111. Two slightly different variants, the 110 and 111 were presented to the air force for evaluation, and were ordered into production soon thereafter. The first mass-production version was the 113 in 1933, of which 49 examples were purchased. This was supplanted in production by the 115 in 1935 and the 117 later than year. Both these series were given light bombing capability as well. For details of design, operational history and 10 variants, click here.

-

The Antonov An-24 (Russian/Ukrainian: Антонов Ан-24) (NATO reporting name: Coke) is a 44-seat twin turboprop transport/passenger aircraft designed in 1957 in the Soviet Union by the Antonov Design Bureau and manufactured by the Kyiv, Irkutsk and Ulan-Ude Aviation Factories. It was the first of a future family of turboprops by Antonov. The An-30 came next with a cartographic configuration, then the An-26 with a military configuration and lastly the An-32 with modernized equipment. The An-132 was intended to be the next member of the An-24 family, but Saudi Arabia's Taqnia ceased cooperation and the only prototype was destroyed, which led to the project being cancelled. A Chinese licensed-built version, the Xi'an Y-7, is heavily based on the An-24, but is not a member of the family. First flown in 1959, the An-24 was produced in some 1,000 units of various versions; in 2023, 93 were still in service worldwide, mostly in the Commonwealth of Independent States and Africa. It was designed to replace the veteran piston Ilyushin Il-14 transport on short- to medium-haul trips, optimised for operating from rough strips and unprepared airports in remote locations. The high-wing layout protects engines and blades from debris, the power-to-weight ratio is higher than that of many comparable aircraft, and the machine is rugged, requiring minimal ground-support equipment. Due to its rugged airframe and good performance, the An-24 was adapted to perform many secondary missions, such as ice reconnaissance and engine/propeller test bed, as well as further development to produce the An-26 tactical transport, An-30 photo-mapping/survey aircraft and An-32 tactical transport with more powerful engines. Various projects were envisaged such as a four-jet, short- and medium-haul airliner and various iterations of powerplant. The main production line was at the Kyiv-Svyatoshino (later renamed "Aviant") aircraft production plant, which built 985, with 180 built at Ulan Ude, and a further 197 An-24T tactical transport/freighters at Irkutsk. Production in the USSR was shut down by 1978. Production continued at China's Xi'an Aircraft Industrial Corporation, which made licensed, reverse-engineered, and redesigned aircraft as the Xian Y-7 and its derivatives. Manufacture of the Y-7, in civil form, has now been supplanted by the MA60 derivative with western engines and avionics, to improve performance and economy, and widen the export appeal. The aircraft introduced in Mongolia was initially planned to be used by the air force, but was eventually handed over to a private airline company for use, and some were later used in research facilities. Since then, as the aircraft has deteriorated, it has been stored in Ulaanbaatar. A total of 1367 units in 24 variants produced. For details, click here.

-

The Hawker Sea Hawk is a British single-seat jet day fighter formerly of the Fleet Air Arm (FAA), the air branch of the Royal Navy (RN), built by Hawker Aircraft and its sister company, Armstrong Whitworth Aircraft. Although its design originated from earlier Hawker piston-engined fighters, the Sea Hawk was the company's first jet aircraft. Following acceptance in the RN, the Sea Hawk proved to be a reliable and sturdy workhorse. A considerable number were also produced for the export market and were operated from aircraft carriers in Dutch and Indian service. The last operational Sea Hawks, operated by the Indian Navy, were retired in 1983. Towards the end of the Second World War, Hawker's design team had become increasingly interested in developing a fighter aircraft that took advantage of the newly developed jet propulsion technology. Prior to this, Hawker had been committed until late 1944 to the production and further development of its piston-powered aircraft, such as the Hurricane, Tempest and Typhoon, to meet the wartime demands for these aircraft. On 1 September 1944, the first prototype of the company's latest fighter aircraft, the Hawker Fury/Sea Fury, conducted its maiden flight; it was this aircraft that would serve as the basis for Hawker's first jet-powered aircraft. The design team studied the potential adaption of the aircraft, having opted to use the Rolls-Royce Griffon-powered Fury prototype as the starting point. The team started with the deletion of the piston engine, with its replacement, a single Rolls-Royce Nene turbojet engine, being fitted in a mid-fuselage position, along with lateral air intakes and a tailpipe which emerged beneath the tailplane. The prospective modifications also included "stretching" the fuselage and moving the cockpit to the extreme front of the fuselage in a re-contoured nose; this design received the internal designation P.1035. Use of the Rolls-Royce Derwent engine had been studied but quickly discarded as lacking power for an aircraft of this size. In November 1944 the P.1035 design was submitted for evaluation by the Air Ministry. In December 1944 Hawker refined the proposed design substantially. The jet exhaust was moved from beneath the tail and re-designed as two short split-lateral bifurcated exhausts (which gained the name "trouser legs"), embedded in the trailing edge of the wing root, which needed a corresponding thickening of the wing root; the air intakes were moved to the wing root leading edge, similar to the contemporary de Havilland Vampire. The shorter unusual bifurcated jet pipe reduced pressure losses in the jet pipe and had the additional advantage of freeing up space in the rear fuselage for fuel tanks, which gave the aircraft a longer range than many other early jets. The absence of wing fuel tanks also meant a thinner wing could be adopted without the penalty of reduced range; to ease manufacture, the elliptical wingform of the Fury was discarded in favour of a straight tapered wing design. The fuselage fuel tanks, being fore and aft of the engine, also provided for a stable centre of gravity during flight. The tail plane was raised to clear the jet exhausts. The Sea Hawk also featured a nose wheel undercarriage arrangement, the first for a Hawker-built aircraft. The aircraft was built to accommodate four 20mm Hispano-Suiza Mk. V cannon. For more details of development, design, operational history and 10 variants, click here.

-

I am collecting more aircraft to add to the profiles in the Aircraft section of this site. I have one supplied as plans for amateur building with a gross weight of 480 kg and a stall speed of 35 kt flaps down, but there is no fixed gear variant. Should it be included in 3-axis rec or GA?

-

The Bücker Bü 131 Jungmann (freshman, young man) is a basic biplane trainer aircraft designed and produced by the German aircraft manufacturer Bücker Flugzeugbau. It was the company's first aircraft, as well as being the final biplane to be produced in Germany. On 27 April 1934, the first prototype Bü 131 performed its maiden flight, which was roughly two years after the company had been founded in Berlin-Johannisthal by Carl Bücker. Anders J. Andersson had led the aircraft's design effort. Comprising both metal and wooden construction, the Bü 131 was designed to be suitable in the trainer role, and even to perform aerobatic manoeuvres. The first deliveries of the Bü 131 occurred in 1934, the Deutscher Luftsportverband (DLV) being a key early customer for the type. Later on, the Bü 131B was selected as the primary basic trainer for the German Luftwaffe. In this capacity, it was operated in large numbers throughout the Second World War. Throughout the 1930s, there had been substantial demand for the Bü 131, multiple large export orders and production licenses were issued as a result. The Kingdom of Yugoslavia was the largest pre-war export customer for the type, flying as many as 400 Bü 131s at one point. Hundreds were produced locally by the Spanish aircraft company Construcciones Aeronáuticas SA (CASA). In excess of 1,300 Bü 131s were operated by the military air services of Imperial Japan under local designations of Kokusai Ki-86 and Kyūshū K9W Momoji. The Bü 131 remained operation with numerous air forces for decades after the conflict, some choosing to retain the type through to the late 1960s. It has proved to be a relatively popular biplane with private pilots, who have often elected to have their aircraft refitted with modern engines for increased performance. The origins of the Bü 131 can be traced back to the work of one man, Carl Bücker. After serving in the Kaiserliche Marine during the First World War, Bücker relocated to Sweden and became the managing director of Svenska Aero AB (Not to be confused with Svenska Aeroplan AB, SAAB). He later returned to Germany with Anders J. Andersson, a young designer from SAAB, and founded a new company, Bücker Flugzeugbau GmbH, in Berlin-Johannisthal during 1932. From the onset, Anderson headed up the company's design team,[note 2] and immediately set about developing the company's first aircraft, out of the efforts for which ultimately emerged the Bü 131. The aircraft was designed to be suitable for aerobatic manoeuvres and training activities. It featured numerous conventional features for such aircraft at that time, being a biplane with two open cockpits in tandem along with fixed landing gear. Both the upper and lower wings were broadly identical in terms of design, to the extent that they could be readily interchanged with on another. Accordingly, all of the wings, which had an 11 degree sweep back and positive stagger, were equipped with ailerons. The wings had a structure largely composed of I-section wooden spars along with a fabric covering. The fuselage of the Bü 131 comprised a structure of welded steel tubing, the covering of which was metal for the front section and fabric around the rear section. Both fuel and oil were accommodated in tanks within the fuselage. Hinged to the side of the fuselage was the twin main legs of the undercarriage, which were furnished with both spring and oil-based shock absorbers, while a spring tailwheel was also present on the underside of the aft fuselage. The mainwheels were outfitted with balloon tyres and brakes. For more details of development, operational history and 13 variants, click here.

-

The Airbus Helicopters H160 (formerly X4) is a medium utility helicopter developed by Airbus Helicopters. Formally launched at Heli-Expo in Orlando, Florida on 3 March 2015, it is intended to replace the AS365 and EC155 models in the firm's lineup. In June 2015, the first test flight took place. It received its EASA type certification in July 2020, and first deliveries were in December 2021. The Airbus Helicopters H160 was first revealed to the public in 2011, at which point it was referred to by company representatives by the designation X4—a designation which implied it to be a follow-on from the Eurocopter X3, a high-speed hybrid helicopter technology demonstrator. Speaking in early 2011, Eurocopter (later renamed as Airbus Helicopters) chief Lutz Bertling declared that the X4 would be a "game changer", contrasting significance of the innovations it would feature with Airbus' development of fly-by-wire controls. Early features alluded to include Blue Edge active tracking rotor blades, advanced pilot assistance functionality, and reduced vibration to "near-jet" levels of smoothness.[2] The X4 was also described as having a "radically different" cockpit, Bertling stating that "The cockpit as we know it today will not be there". It was also announced that the X4 would be introduced in two stages: an interim model in 2017 with some of the advanced features absent, and a more advanced model following in 2020. The development program for the X4 cost €1 billion ($1.12 billion). Cutting-edge features, including proposed highly advanced control systems, were toned down or eliminated as too risky or costly. On 3 March 2015, the X4 was formally unveiled under the H160 designation. It has been marketed as a successor to the company's existing Eurocopter AS365 Dauphin and competes with the AgustaWestland AW139, Sikorsky S-76, and Bell 412; Guillaume Faury, Airbus Helicopters Chief Executive, referred to the H160 as being "the AW139 killer". The H160 began Airbus Helicopter's re-branded naming convention; starting 1 January 2016, helicopters in the same range shall bear the 'H' designation, resembling how Airbus names their commercial aircraft. The Airbus Helicopters H160 takes advantage of several advanced manufacturing technologies and materials in order to produce a lighter, more efficient design. One weight-saving measure was the replacement of conventional hydraulic landing gear and brakes with electrical counterparts, the first helicopter in the world to do so; according to Airbus the elimination of hydraulic components makes the rotorcraft both lighter and safer. In 2015, Airbus claimed that the all-composite H160 would deliver the same basic performance as the rival AgustaWestland AW139 while being 1 tonne lighter, having a lower fuel consumption and offering 15–20% lower direct operating costs. The composite fuselage also provided for greater design freedom of the rotorcraft's external styling. During the aircraft's development features such as full de-icing equipment and a fly-by-wire control system were deemed too heavy or costly for the benefits they would deliver and were eliminated. The H160 is the first rotorcraft to feature the Blue Edge main rotor. The main rotor has five blades which incorporate a double-swept shape that reduces the generation of blade–tip vortices. The resulting reduction in Blade-vortex interactions, a phenomenon which occurs when the blade impacts a vortex created at its tip, allows for a 3–4 dB noise reduction and raises the effective payload by 100 kg (220 lb) compared with a scaled Eurocopter AS365 Dauphin rotor design. The main rotor is also tilted 4° forward to reduce excessive pitching in forward flight and 2° to the right to compensate for translating tendency from the tail rotor's thrust. Aerodynamic innovations include a biplane tailplane stabiliser for greater low speed stability, and a quieter canted fenestron which combined produce an extra 80 kg of lift. The H160 is the first civilian helicopter to utilise a canted fenestron anti-torque tail rotor. The H160 will be powered by two Safran Arrano turboshaft engines; a second engine, the Pratt & Whitney Canada PW210E, was to be offered as an alternative option, but this was eliminated due to insufficient power output and to reduce design complexity. A redundant backup for the gearbox lubrication system enables in excess of five hours of flight following a primary failure without causing mechanical damage. For more details of desvelopment, design, flight testing and variants, click here.

-

The Airbus Helicopters H140 is a light twin-engine utility helicopter developed by Airbus Helicopters. Formally launched at VERTICON in Dallas, Texas on 11 March 2025, it is intended primarily as a medical helicopter. It is planned to enter service in 2028. The Airbus Helicopters H140 was publicly unveiled in March 2025. The H140 incorporates several design elements from the Airbus Helicopters fleet, including a fenestron tail rotor, a five-blade bearingless main rotor, Helionix avionics with a four-axis autopilot, dual-channel FADEC and a rear clamshell door for patient and cargo loading. A notable addition is a T-tail-shaped tail boom, which Airbus claims provides 80 kg of additional lift in forward flight compared to the H135 and was first used on the Airbus Bluecopter Demonstrator. The H140 is powered by dual Safran Arrius 2E engines, a variant of those used in the H135, producing a combined output of 1,400 shp—approximately 6% more power than the H135 T3. Airbus has identified helicopter emergency medical services (HEMS) as the primary market for the H140, citing improvements in cabin vibration and noise reduction due to the new rotor system. Additional features include built-in medical lighting in the cabin roof and an increase of approximately 1 cubic meter in cabin space compared to the H135. The tail boom has been raised slightly from the H135. at the rear, providing improved access to the rear doors for patient and cargo loading, as well as increased ground clearance for the fenestron, enhancing operational safety. No performance spec yet on Airbus website.

-

Nah. Just a Facebook post.

-

-

The Aero Eli Servizi Yo-Yo 222 (sometimes written YoYo) is an Italian helicopter designed and produced by Aero Eli Servizi of L'Aquila. The aircraft is supplied complete and ready-to-fly. The Yo-Yo 222 was initially designed for a higher gross weight of 495 kg (1,091 lb), but later versions were lightened to allow a gross weight of 450 kg (992 lb) to qualify under the European Class 6 microlight helicopter rules. The aircraft features a single main rotor and tail rotor, a two-seats-in side-by-side configuration enclosed cockpit, skid landing gear and an American-made four-cylinder, air-cooled, four stroke 172 hp (128 kW) Lycoming O-320 engine. Greatly resembling the Robinson R22, reviewer Werner Pfaendler, describes it as "obviously the result of a close look at the world's bestselling two-seater helicopter, the R22." For lightness the aircraft fuselage is made with extensive use of carbon fiber reinforced polymer and fibreglass. Its two-bladed rotor has a diameter of 7.66 m (25.1 ft). The initial version of the aircraft has a typical empty weight of 322 kg (710 lb) and a gross weight of 495 kg (1,091 lb), giving a useful load of 173 kg (381 lb). With full fuel of 68 litres (15 imp gal; 18 US gal) the payload for the pilot, passenger and baggage is 124 kg (273 lb).

-

-

The Sikorsky S-97 Raider is a high-speed scout and attack compound helicopter based on the Advancing Blade Concept (ABC) with a coaxial rotor system under development by Sikorsky Aircraft. Sikorsky planned to offer it for the United States Army's Armed Aerial Scout program, along with other possible uses. The S-97 made its maiden flight on 22 May 2015. Sikorsky's earliest attempt at a fast compound helicopter with stiff coaxial rotors was the Sikorsky S-69 (XH-59A) flown in the 1970s. Its top speed was over 260 knots but its excessive fuel consumption, vibration and complexity requiring the full-time attention of two pilots led to the program's cancellation. These problems were largely solved on another attempt by the Sikorsky X2 technology demonstrator in 2010. First proposed in response to a Request for Information for the Armed Aerial Scout (AAS) program in March 2010, the S-97 was formally launched on 20 October 2010. It was intended as a contender for a United States Army's requirement to replace the Bell OH-58D Kiowa Warrior. Other military roles are possible, the U.S. Special Operations Command having expressed interest in the S-97 as a replacement for the MH-6 Little Bird, and the possibility of adapting it for civilian applications also exists. Sikorsky plans to build two prototypes of the S-97 as demonstrators. One prototype (P1) will be used for flight testing, while the second (P2) is planned for use as a demonstrator. The first prototype was planned to fly in late 2013 or early 2014. Sikorsky started construction of the two prototypes in October 2012. In September 2013, Sikorsky began final assembly of the first S-97 following delivery of the single-piece, all-composite fuselage by Aurora Flight Sciences. In February 2014, construction of the first S-97 prototype was one-quarter complete. Simulated bird strikes testing had been conducted on the fuselage at speeds of up to 235 kn (435 km/h; 270 mph), the S-97's expected maximum flight speed. Drop tests were also performed to ensure the fuel tanks' safety in the event of a crash. Sikorsky is exploring civil applications for the S-97, such as transporting personnel between offshore oil platforms. Sikorsky and partner Boeing are to use the S-97's technology and design process as a basis to develop the SB-1 Defiant, a high-speed rigid rotor co-axial rotorcraft, for the army's Joint Multi-Role Technology Demonstrator (JMR TD) program. The JMR TD is the precursor to the army's estimated US$100 billion Future Vertical Lift (FVL) program to replace the UH-60 Black Hawk utility helicopter and AH-64 Apache attack helicopter. Sikorsky targeted the S-97 for the AAS program, aiming for the helicopter to fly before the Army downselected. Sikorsky invested $150 million and its 54 suppliers[16] (who provide 90% of the parts) spent the remainder of a total of $200 million on two prototypes; production models aim to meet the program's $15 million unit cost target. However, the Army ended the AAS program in late 2013. Budget projections for FY 2015 included retiring the U.S. Army's OH-58 Kiowa fleet and transferring AH-64 Apache attack helicopters from U.S. Army Reserve and U.S. Army National Guard to the active Army to perform the aerial scout role. Sikorsky suggested the possibility of buying the S-97 to replace lost Apache for armed helicopter needs. Sikorsky proposes S-97 as FVL-CS1; the light scout helicopter. On 5 May 2014, Sikorsky opened the S-97 production hangar during the rollout of the CH-53K King Stallion. At that point, the mostly-composite airframe was almost assembled, including some of the electrical wiring and avionics, missing elements were the transmission, drive train, engine, coaxial rotor, and pusher propeller. The S-97's first military customer is aimed to be the U.S. Special Operations Command to replace the MH-6M Little Bird. Unspecified foreign militaries have shown interest in the S-97; it may be difficult to get approval for export for a next-generation helicopter if the US military does not yet have it. The Raider is a prototype, so the first customer would need to finance a production development program. Its avionics were powered on in June 2014, with rollout on 2 October 2014. For details of design and operational history, click here.

-

The Ultracraft Calypso is a family of Belgian homebuilt aircraft designed and produced by Ultracraft of Heusden-Zolder, introduced in the 1990s. The aircraft is supplied as a complete ready-to-fly aircraft or as a kit for amateur construction. The Calypso line all feature a strut-braced high wing, fixed conventional landing gear with optional wheel pants and a single engine in tractor configuration. The single-seat Calypso 1 is made from a combination of wood and metal with its flying surfaces covered in doped aircraft fabric and a fibreglass cowling. Its 8.84 m (29.0 ft) span wing has a wing area of 11.6 m2 (125 sq ft) and is supported by "V" struts and jury struts. The cabin width is 61 cm (24 in). The acceptable power range is 40 to 65 hp (30 to 48 kW) and the standard engines used are the 40 hp (30 kW) Rotax 447 or the 50 hp (37 kW) Rotax 503 two-stroke powerplants. The Calypso 1A has a typical empty weight of 155 kg (342 lb) and a gross weight of 285 kg (628 lb), giving a useful load of 130 kg (290 lb). With full fuel of 40 litres (8.8 imp gal; 11 US gal) the payload for the pilot and baggage is 103 kg (227 lb). The standard day, sea level, no wind, takeoff with a 40 hp (30 kW) engine is 61 m (200 ft) and the landing roll is 46 m (151 ft). The manufacturer estimates the construction time for the Calypso 1A from the supplied kit to be 300 hours. By 1998 the company reported that 12 kits had been sold and five Calypso 1s were completed and flying. Variants Calypso 1A Initial version, single-seat with 40 to 65 hp (30 to 48 kW) engine. Calypso 1B Single-seat version with Citroën Visa automotive conversion engine or 65 hp (48 kW) Rotax 582 two-stroke, liquid-cooled powerplant. Calypso 2A Two-seat version with a wingspan of 9.05 m (29.7 ft) and a wing area of 15 m2 (160 sq ft), powered by a 65 hp (48 kW) Rotax 582 aircraft engine or a BMW automotive conversion engine. The 2A was designed to comply with the Fédération Aéronautique Internationale microlight category, including the category's maximum gross weight of 450 kg (992 lb). The aircraft has a maximum gross weight of 450 kg (992 lb). Calypso 2B Two-seat version with a wingspan of 8.05 m (26.4 ft) and a wing area of 13.4 m2 (144 sq ft), powered by an 85 hp (63 kW) Jabiru 2200 aircraft engine or a BMW automotive conversion engine. The 2B was designed to comply with the Fédération Aéronautique Internationale microlight category, including the category's maximum gross weight of 450 kg (992 lb). The aircraft has a maximum gross weight of 450 kg (992 lb).

-

In January 1993 the construction of two prototypes of the SM-92 Finist (a magical bird that was transformed into a Prince) commenced, the first (RA-44482) flying on 28 December 1991. Another (RA-44484) commenced a round-the-world sales flight through Europe, Canada, Alaska and Siberia in August 1995, covering 30,000 km (18,640 miles) in 160 flying hours. A few variants were proposed, including the SM-92P armed version, the first of which (RA-44493) was first flown in August 1995. This model was aimed particularly at the border patrol role, and, fitted with armament, a number were supplied to the Russian Federal Border Service. Consideration was also given to production by Aerostar SA in Romania, and assembly in Canada. A variant fitted with a Pratt & Whitney Canada PT-6 turboprop was also proposed. The first production aircraft (RA-44485) was delivered to an operator in the United Kingdom in 1995. The type was also built in the Czech Republic by Zlin as the Z-400 Rhino and it would appear this was where later production aircraft emanated. The Finist was in the class of the DHC-2 Beaver but had less power and its purchase cost was less than that of a second-hand Beaver. Construction was all-aluminium, stressed skin monocoque, the design being aimed at the market where repairs would be possible under field conditions, and also to replace Beavers. The airframe hds a life of 10,000 hours or 20,000 landings. Undercarriage was non-retractable tailwheel. Four-section, three-position Fowler flaps were installed. Initial production commenced at the facility of the Smolensk Aircraft Factory, the designer being Slava Kondratiev, who was also involved in the design of the Yak 55, and Sukhoi Su-26, Su-29 and Su-31. The type was designed and built to FAR 23 and JAR 23. The basic aircraft was fitted out to take a pilot and six passengers but could quickly be converted to carry six parachutists, or 600 kg (1,323 lb) of freight, or be used as an air-ambulance or crop sprayer. In the latter role it could be fitted with a hopper to carry 600 kg (1,323 lb) of agricultural chemicals. A variant fitted with floats was also proposed. Other roles included forest surveillance, patrolling electric power lines, gas pipeline inspection etc. In 2002 an example of the Finist (the second prototype – RA-44484 – c/n 00 003), arrived in Australia flown by two Russian pilots on a round-the-world tour. The aircraft was placed on display at the Airshows Downunder event at Avalon, VIC and was subsequently seen at many venues around the country, eventually in 2003 being noted as based at Archerfield, QLD where it had “www.flyingfighters.com.au” painted on the side of the fuselage, advertising a local aviation museum. It later remained in Australia and was regularly seen at venues along the east coast. It was noted at Gympie, QLD and was used for sky diving operations. However, it was eventually exported to Spain where it became HA-NAH on 10 February 2007 and commenced operations with Skydive Spain. In more recent times a new variant of the Finist, known as the SMG-92 Turboprop Finist, has been made available. This aircraft is fitted with the Walter M.601D-2 reverse flow free-driving turbine producing 537 kw (721 shp). This Finist was originally built by the Smolensk Aircraft Factory, being initially flown with an M-14P radial engine. A military variant known as the SM-92P was produced with rocket launchers, two machine-guns fitted to the lower fuselage, and another mounted in the doorway. It is believed five development aircraft and 10 production aircraft were built before production was suspended. The prototype was later converted to the Turbo Finist. When the turbine was fitted the aircraft was taken to Aerotech in Slovakia where it became HA-YDF. Initial turbine fitted was the M.601D-2 providing 400 kw (536 shp) and first flew on 7 November 2000. Thereafter six early production aircraft were converted to turbine power and a number were used for parachuting duties. A decision was then made, as mentioned, to build the type in the Czech Republic as the Zlin Z-410 Rhino with a 360 kw (485 shp) Orenda OE600 V-8 diesel engine but only one aircraft was fitted with this engine by Moravan Otrokovice in the Czech Republic. Other engines have been fitted at various times, including the Pratt & Whitney PT-6A and Allison 250. The type has also been operated on wheeled undercarriages, floats, amphibious floats and skis. It has been used for military and civil air survey, scientific work, air-sea rescue, air-taxi, medevac, glider towing and crop spraying. No further examples are known to have visited this region. Variants SM92 Finist Basic version, powered by 270 kW (360 hp) Vedeneyev M14P radial engine. SM92P Finist Armed version for Border guard duties. Two fixed forward firing PK machine guns and one inside cabin firing through open cabin doors and two rocket launchers. SM-92T Turbo Finist Version powered by Walter M601 turboprop engine. One prototype converted. SMG-92 Turbine Finist Walter M601 powered version built in Slovakia by Aerotech Slovakia for use in skydiving. At least six converted. Zlin Z400 Version powered by Orenda OE600 V-8 engine, planned to be built by Moravan Otrokovice in the Czech Republic. One built. Orbis Avia SM-92T SM-92T built by Czech aircraft manufacturer Orbis Avia. One built 2015, fitted with 560 kW (750 hp) GE H75 turboprop in 2017.

-

The Avid Aircraft Magnum is an American two-seat homebuilt cabin monoplane which was designed and sold as kits by Avid Aircraft of Caldwell, Idaho. The Magnum is a high-wing strut-braced monoplane with a welded steel tube fuselage, the wings have aluminium spars and wooden ribs covered with Ceconite. The Magnum was sold without an engine and was designed for a range of Lycoming engines from 115 to 180 hp (86 to 134 kW), for example the Lycoming O-235, O-320 or the O-360. The enclosed cabin has side-by-side configuration seating for two with an option for an additional seat in the baggage area for two children or a small adult. It has a fixed conventional landing gear with a tailwheel and some are fitted with floats. By 2010 the aircraft was back in production by the Airdale Flyer Company of Rhinelander, Wisconsin. The Airdale version includes some modifications, including enlarged landing gear, plus optional tricycle landing gear.

-

Traced the rego. It was a Progressive Aerodyne Searey.

-

A 61 year old pilot was lucky to escape injury when his light plane crashed upside down at Norwell Qld. The plane, which looked similar to the photo below, was moderately damaged and identification was difficult from the TV footage.

-

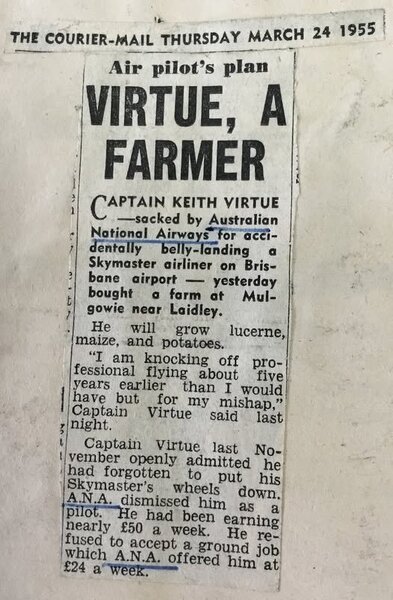

Note the wages in this clipping. There are a series of photos of this aircraft, including one sitting on it's belly, at this address.

- 1 reply

-

- 1

-

-

Sorry about the messing around with the photos, guys. Accidentally loaded the unedited ones. Sorted out now. 250-300 kb instead of 90-100 kb, and dark shadows under exposed. Details of processing these photos is explained in a post in the Photography topic on Social Australia. Click here.

-

The Aero East Europe Sila (English: force, power or strength and also short for Serbian industry light aircraft) is a family of Serbian ultralight and light aircraft, designed and produced by Aero East Europe of Kraljevo and later of Jagodina, introduced at the AERO Friedrichshafen show in 2013. The design is supplied complete and ready-to-fly. The Sila 450 C was designed to comply with the Fédération Aéronautique Internationale microlight rules, while the larger aircraft in the family fit into the EASA CS-VLA category. All feature a V-strut-braced high-wing, an enclosed cabin, fixed tricycle landing gear and a single engine in tractor configuration. Reviewer Marino Boric described the design in a 2015 review as "very robust". Variants Sila 450 C Two seat "Cruiser" model, with a semi-monocoque structure made from aluminium sheet and a maximum take-off weight of 450 kg (990 lb). Its 9.4 m (30.8 ft) span wing employs a NACA 5417 airfoil, has an area of 11.94 m2 (128.5 sq ft) and flaps. Standard engines available are the 80 hp (60 kW) Rotax 912UL, 100 hp (75 kW) Rotax 912ULS and the 115 hp (86 kW) Rotax 914 four-stroke powerplants. German LTF-UL and Serbian ultralight certified. Sila 750 C Two seat "Cruiser" model, with a semi-monocoque structure made from aluminium sheet and a maximum take-off weight of 750 kg (1,650 lb). Its 9.47 m (31.1 ft) span wing employs a NACA 5417 airfoil, has an area of 11.94 m2 (128.5 sq ft) and flaps. Standard engines available are the 100 hp (75 kW) Rotax 912ULS, the 115 hp (86 kW) Rotax 914 and the 160 hp (119 kW) Lycoming O-320 four-stroke powerplants. The aircraft is undergoing EASA CS-VLA and Serbian certification. Sila 750 S Two seat STOL model with full-span Junkers flaperons and a maximum take-off weight of 750 kg (1,650 lb). Sila 750 MT Three seat Medical Transport model, with a semi-monocoque structure made from aluminium sheet and steel tubing and a maximum take-off weight of 750 kg (1,650 lb). Its 10 m (32.8 ft) span wing employs a NACA 65-018 airfoil, full-span Junkers flaperons, has an area of 14.30 m2 (153.9 sq ft). Standard engines available are the 100 hp (75 kW) Rotax 912ULS, the 115 hp (86 kW) Rotax 914 and the 160 hp (119 kW) Lycoming O-320 four-stroke powerplants. The aircraft is undergoing EASA VLA and Serbian certification. Sila 950 Four seat model, with a maximum take-off weight of 950 kg (2,090 lb). Standard engines available are the 115 hp (86 kW) Rotax 914 and the 160 hp (119 kW) Lycoming O-320 four-stroke powerplants. The aircraft is no longer advertised on the company website.

-

The ACBA Midour, Midour 2 and Midour 3 are a series of glider tugs manufactured by the Aéro Club du Bas Armagnac in France, and named after the Midou River. The Midour is a double-seat, low-wing monoplane of conventional configuration, fitted with a fixed, tricycle undercarriage. Developed in the workshop of the ACBA using the wings of a Robin DR400, the Midour first flew in 1993 and four additional examples to the original design have been built, along with two modified versions. Although the Midour is sometimes equipped with only a single seat, a passenger can be carried behind the pilot, to assist in the release of gliders being towed. Variants ACBA-7 Midour Original version with 180 horsepower (130 kW) Lycoming O-360 engine; five built. ACBA-8 Midour 2 Improved version with entirely new wing design. One built. ACBA Midour 3 Optimised, quieted version of Midour 2 with new fuselage and canopy, designed to be especially quiet due to noise pollution concerns. One built.

-

Translated from a Spanish language website. Sora-e is a single-engine two-seater, with propeller of wood and carbon. Its basis is the Sora, a plane to aerial acrobatics, with combustion engine, which was the first model produced by ACS. With structure of carbon fiber, weighs about 650 kilos and is 8 meters tall wingspan. Uses two electric motors Emrax of 35 kW each, produced by the company Slovenian Enstroj. The motors are powered by six sets of polymer-ion lithium batteries, which together deliver 400 volts. The apparatus features a rise ratio of 1,500 feet per minute. Its flight range is 90 minutes at 190 km/h, reaching a maximum speed of 340 km/h