-

Posts

3,528 -

Joined

-

Last visited

-

Days Won

49

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by RFguy

-

Light plane crash The Oaks, 30 March 2023 (edited)

RFguy replied to red750's topic in Aircraft Incidents and Accidents

Thanks OneTrack et. al for the info. Oh combustable and flammable are different things?. Well there ya go I learned something. OK doing my research, there are quite alot of limits imposed. fair enough. The Jab takes 140 litres . The Archer is 182 ish. The Archer has a MOGAS STC which I might take advantage of , at least in winter. Might ask users and see if anyone has had issues of any sort that can be put down to fuel. But it wont be local pump gas, IE will be drum or better. Or some means of verifying the integrity of the pump ULP before it goes in the certified aircraft, per the STC guidelines/ Lycoming. Not a money saver, just trying to keep the lead deposits out of the engine if I can. Although, before too long, might we have AVGAS-ULP ? AS1940 has a bit to say, now need spill response kit for all storage......and then there are state rules...golly. talk about varied ! .... locally : Interesting, on rural properties, the bunds around it to hold spills etc must have the capacity of 20 minutes of fire fighting water. At home , between 100 and 250 litres depending on where you are, and danger signs may be required to be displayed. Hard to find much info at the 'single drum storage' size. Might talk to fuel trailer providers and see what they say. and the Sydney Recreational flying club at The Oaks. The club has expressed interest in a ULP fuel trailer at Cowra- sharing in the running / use of that that would most likely be the best overall economy of scale. -

Light plane crash The Oaks, 30 March 2023 (edited)

RFguy replied to red750's topic in Aircraft Incidents and Accidents

I want to investigate buying drum or drums of ULP98. Anyone here much experience with buying drums? I bet there are. IE not necessarily premium unleaded with all the fancy additives, just ULP98, which is listed in a few of the available products. Is a single drum on a trailer and approved screw into drum pump/ filter reasonable or is it better to have a bigger - say 600-100 ltrs fuel trailer and fill that up from a truck ? I dont really want to encounter / infringe on needing large volume storage permits etc. And a drum a week would be plenty. -glen -

Light plane crash The Oaks, 30 March 2023 (edited)

RFguy replied to red750's topic in Aircraft Incidents and Accidents

Yeah, my comments relate to Gen 1,2,3. In my opinion - systematic issues of Gen1,2,3 are pretty well covered off and mitigated in Gen4 (head integration). and other non head stuff like flywheel bolts / attachment - sorted, propeller flange extra dowels, - sorted. Pistons seem to still go bang, but they are few in numbers. Lycoming have lightweight pistons that fail, also. Not alone.... With exception - that , IMO, the TBO on AVGAS ( without additive that reduces lead products buildup ) is about 300 hours (Gen1,2,3,4), and that fresh ULP98 is best fuel for Jabirus by far. Running 95/98ULP in Jabirus that have had lots of avgas and have lots of buildup I would avoid because of potential glow/preiginition issues due to buildup. -

Light plane crash The Oaks, 30 March 2023 (edited)

RFguy replied to red750's topic in Aircraft Incidents and Accidents

As I have mentioned before.. There are a few things , IMO, that Jabiru Engines SHOULD HAVE been alot more proactive of fixing / SB issue. Someone in the company, IMO, made a judgement call (which i disagree with) that IMO, they considered the reputational loss was acceptable and allowed parts and systems to fail in airborne aircraft. (or were not sufficiently competent and didnt understand the rather basic problems) . However I think an equal number of Jabiru engine failures are due to, let's call it... "Variable maintenance practices". There is half of me that's had about enough of the Jabiru company mindset, and makes me want to sell my J230..... but the other half of me knows that the J230 airframe is one of the best flying options around. Economy, speed, performance.,- that wing is gorgeous to fly with compared to GA trucks. Putting aside I have bought an Archer1 and am studying for my Instrument Rating - that is a separate pathway - the J230 and the Archer are two completely different mission providers. -

Microair 760 Radio - High pitch tone

RFguy replied to ozzietriker's topic in Instruments, Radios and Electronics

sounds like the mic is feeding back through the intercom / sidetone facility . turn down the sidetone, or mic gain, or intercom tweaks. is the volume of the squeal track with the volume control on the panel ? -

Oil cooler placement and ducting advice - Rotax 912ULS, CH701

RFguy replied to Marty_d's topic in Engines and Props

check whole oil system checks per rotax manual : HAS A OIL SYSTEM VACCUUM CHECK BEEN DONE PER THE ROTAX INSTALL MANUAL ?? YES / NO ???? (1.4) HAS OIL SYSTEM AIR PURGING BEEN DONE PER ROTAX MANUAL ? (1.5) HAS THE CRANKCASE PRESSURE BEEN CHECKED PER ROTAX MANUAL ? (1.3) ARE LENGTHS AND MIN DIAMETERS AND BENDING RADII BEEN OBSERVED PER ROTAX MANUAL ? What were the values written down in ther maintenance book ? What was the vaccum reading at the T ? Section : INSTALL MANUAL. Lubrication system, 1.1, 1.2, 1.3. 1.4 1.5. If this has not been done either re-educate or sack your mechanic. -

I dont like carbon fibre at all if it is damaged- mostly is not repairable, splintered, fractures along weave lines . Terrible stuff. Fibreglass would be #1 choice, especially with chance of needing repair/damage over the lifespan. As for fashion ? Customers need to be educated on the disadvantages of carbon fibre, and advantages of fibreglass.

-

Oil cooler placement and ducting advice - Rotax 912ULS, CH701

RFguy replied to Marty_d's topic in Engines and Props

a few pictures would be useful for us. Rotax might say 140 is max but reality the mfrs will tell you 110C would be maximum continuous temperature . Engines oils get thinner with higher temps and this also affects the "oil bearing" that can be provided. between bearings and journals. Not to mention cylinders and pistons.... If using a radiator of area of say, 160cm2 is used, (rotax minimum suggestion) in some service note, that's for a min 75 kts aircraft. you might need bigger for slower aircraft. If you have a good size radiator already, that would imply something bad going on (assuming the temperature measurement is sound) , airflow throu the core is not as you expect- is the core blocked possibly ??? Is the hose between the oil pump inlet and the radiator sucking in ? there is high vaccuum there. Is the oil cooler too high pressure drop ? ****IE is the oil flow slow? BECAUSE slow oil flow will yield higher temperatures on exit from the engine. slow flow means high temperature differences. slow flow means cooler exit from the radiator and hotter exit from the engine . Fast flow reduces temperature difference (rise) . -

tell them hovercraft. I've found the Ninja 250 radiator is a good size for a 'tax, has conveniently located pipes - a good one (19mm). you want 25mm for the 'tax I presume. $100 at various local sellers. If you are pressed for frontal area, consider a triple core. You'll have plenty of pressure to drive it.

-

Looking good skip. that would be my approach. you still get some cylinder cooling this way. Who made your radiators- I was looking to do that on the Jabiru but cost of two custom radiators was quite high. what is the cylinder at the bottom ? oil -water heat exchanger ? or cabin heater ? the formula for inches of water pressure can be simplified to (airspeed knots * airspeed knots) / 1600

-

Log into CASA "self service" and you can see the status of your requests... and there is a Service request number that you can use to ask about progress. you can apply for username password for this service easily enough. My RPL conversion application is sitting there waiting to be looked at.. https://customer.casa.gov.au/webclient/index

-

I've never seen any stone damage in the very low mounted Jabiru oil cooler. Do propellors (on GA) 'suck' stones in from in front of them , or do they stir up the stones beneath them ? As I commented elsewhere, its all about whether you can acheive an air pressure differential across the radiator, which is VERY cheaply assessed with a clear bit of tube and some water. if its frontal facing, you can estimate the frontal pressure using the formula for inches of water = ((airspeed knots * airspeed knots ) * 25 ) / 40000 Then have a tube from behind the radiator to static . performance will be compromised by how much air is getting into the cowl (if the radiator exit is in the cowling) If the radiator is ducted, like many GA, have the tube across both sides of the radiator.

-

Oil cooler placement and ducting advice - Rotax 912ULS, CH701

RFguy replied to Marty_d's topic in Engines and Props

Hi Marty. Have you had time to read through the 912 and 914 (has more useful info) rotax installation manuals ? there is lots of meat in them, Now, what i would be looking for is : can you satisfy / provide the required pressure differential across the cooler? That's the $64 question. The thin coolers like std rotax - well there is very much ambient temp and heat input variables, but they can work for typical 912 usage with as little as 2.5" of water , but the deep coolers like #800075 , needs about 5 inches of water for typical loads. Slowish aircraft like the Archer, (100 kias cruise) they have an # 800075 aeroclassics cooler ( a deep cooler that needs lots of differential pressure to work) - it is mounted on some 4" scat from the nose of the plane and tghe cooler, with the duct mounted at the firewall. that cooler is same as factory Jabiru used for 3300. so really, it comes down to if you can make pressure across the cooler. poke a tube with water meas into the shroud at the cooler to find out ... Dont forget you need to duct air over the cylinders (per Rotax) where possible. otherwise a ton of extra heat load goes into the water system usually from the rear cylinder not getting the blast. -

Light aircraft crash - NT - 25/12/2022 - 2 dead

RFguy replied to onetrack's topic in Aircraft Incidents and Accidents

Nice comment Nev : "If the plane is already loaded say in a turn or a dive recovery the effect of a gust will compound the air loads you already have. " yes, very true. In the simulator, I've overdone the airframe a few times during (radical) upset recovery in IMC....I'll calculate at what height (minimum) a vertical dive and consumate airspeed is unrecoverable (IE insufficient height to pull the aircraft out of the dive without damaging the airframe) . -

Light aircraft crash - NT - 25/12/2022 - 2 dead

RFguy replied to onetrack's topic in Aircraft Incidents and Accidents

Dynamic Gust Loads in https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_25_341-1.pdf Required reading for everyone everyone to read sections 5 and 6 from that AC. (dont need to read the lot) -

Light aircraft crash - NT - 25/12/2022 - 2 dead

RFguy replied to onetrack's topic in Aircraft Incidents and Accidents

not quite , It is the speed beyond where the the lift produced can damage the aircraft. example: your aircraft is 1250 lbs, and rated for 2G. and.. that the maximum lift AoA is 25 degrees. and it produces 2500 lbs of lift at 56 kts at 25 deg AoA. now, say you are flying along at 5 deg AoA at 56 kts, and the wing is producing 1250 lbs = IE same as your weight, S&L flight. then you yank the control stick back and produce 25 deg of AoA, -- now yoru airspeed is still 56 knots, and now the wing is producing 2500lbs, which is 2x the 1250 lbs weight, - and thus 2G of force - this is the maximum you can tolerate. if you yank the stick back and push the aircraft through the maximum lift AoA, and BEYOND , then the wing goes down the other side of the lift curve in a stall. no bother. So, you survived, the wings didnt fall off . But if you'd been flying S&L at 80 kts, and you yank the control stick back to produce 25 deg AoA, now the wing produces ( 80/56 )squared = 2.04 x as much lift as at 56 kts, now you have 5000 lbs of lift, or 4G. your wings fall off. for a GUST and TURBULANCE - and this is what I didnt first explain - this is for a fictional gust of , if the aircraft gets belted up by a gust, or the pilot applies some control input in resposne, IE hit by a gust causing the aircraft attitude to change its AoA - the aircraft goes from flying S&L to perhaps being steeply pitched up, high AOA- then below Va, this will result in lift being below the maximum that the airframe can tolerate. If it gets hit by a gust etc and the aircraft gets pushed HIGHER than its maximum lift AoA, no bother- the wing will stall - IE beyond the maximum angle on the lift curve - IE putting an upper bound on the lift produced. The same limit can occur if the wind gust vector is such that it produces a high AoA. Like, a gust from under forward of your nose. See section on Dynamic Gust Loads in https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_25_341-1.pdf -

Light aircraft crash - NT - 25/12/2022 - 2 dead

RFguy replied to onetrack's topic in Aircraft Incidents and Accidents

No. google "FAA definition of Va". FAA defines this as : the airspeed at which the airplane, subject to a sudden control input , or , gust will stall rather than exceeding the design structural limitation / maximum load limit. And more weight on board means higher stall speeds (as usual) . If you fly faster, the wing can produce more lift. IE for Va = 80 kts.....you are flying along at 70 kts and yank the column back to maximum AoA. below Va, the wings dont fall off. you are flying along at 100 kts, and yank the column back to maximum AoA , the wings produce a sh1t ton more lift (2.04x precisely) , you exceed the structural limitation of the aircraft, the wings fall off. The relationship with flying in turb is that you are hit by a gust at some angle which emulates a higher AoA and hence instantaneous lift. bad. See section on Dynamic Gust Loads in https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_25_341-1.pdf -

Light aircraft crash - NT - 25/12/2022 - 2 dead

RFguy replied to onetrack's topic in Aircraft Incidents and Accidents

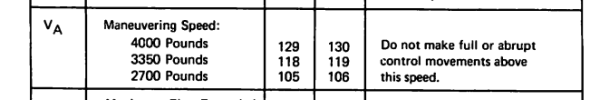

C210 crash : Well, the weather radar/ time/ location of crash has good correlation. Not sure why the pilot did not fly around the storm, if indeed that was the cause. Always slow down to Vmaneuvering in turbulence ! It might be slower than you think if the aircraft is low in weight compared to max weight. According to the (pressurized) P210N POH : (and same in a T(urbo)210N) empty weight abotu 2200, so 210 litres, 2 pax and some luggage and tie downs etc probably 2950 lbs - IE around 111 kts -

So, I see Justin has some coarse finned heads, they might be good. there are a few from time to time as you know on jab parts facebook. another option is ask on jabcamit forum. I have some but they've got plenty of recession . Need milling down 0.9mm (to take the recession out to get square again ) and dropping copper shims in (I have the shims- got them water jet cut) these guys have the new heads - recommended : Philip Gibbs Shadow Lite CC t/a Jabiru Aircraft SA CAA AMO L14 & 909 George Airport, Aviation Area, Hangar 22, National Rd, George, Western Cape, South Africa PO Box 2540, George, 6530, South Africa Ph: +27 44 - 8769991 / 2 Fax: +27 44 - 8769993 Email: [email protected] <mailto:[email protected]> Website: www.jabiru.co.za <http://www.jabiru.co.za/> Office Hours: Mon-Thurs 08h00 - 16h45 Friday 08h00 - 15h45 Click on this link for a view into our factory: https://youtu.be/vPYUwuFTKSM

-

flat top pistons were still used up to at least3300#2575. (mid gen 3) the springs in jabs are weak. I went right through that investigation, and it is elsewhere on the site- jab valve springs are about 1/3 the tension that those lifters are usually used with. Double springs are approx same overall tension as singles. New head. simple fix. you might replace the rocker bushes while you are at it. (small arbor press required) - watch out for slithers of the material being extruded during the extraction and insertion)..

-

time for a new head. Jabiru South Africa. AUD1250 I think

-

Looks like quite alot of recession there- or is that a high crust ? Alot of recession would indicate long term overheating. remember, once they get soft, essentially over tempered, its all over even if you keep the temperatures down....

-

I think the "there is no point unless it makes a 5 knot difference" statement is not the right way to look at it. Many 5 knot gains come from numerous 1 knot gains all put together.

-

Hey all youse radio gurus!

RFguy replied to danny_galaga's topic in Instruments, Radios and Electronics

yes, grounds carry return currents. because the ground wire of your speaker carries significant current, if it shared a ground wire with the microphone, there might be enough voltage drop in the (common) ground wire , and inject voltage into the microphone circuit, and you could get feedback. happy to do a diagram... so, where possible, bring the mic grounds and the speaker grounds back separately to these pins. -

Hi Neil- good info - yeah- SKyecho should see a 200W TSO Mode S about 30nm away, if everything is goign for you ***However for terminals right above or right below - there is (usually) significantly less antenna sensitivity for a body mounted whip antenna above and below - compared to our on the horizon. probably reduces the immediate up and down range by 10x . which is rarely an issue.... once outside a 60 deg cone, you're probably less than a factor of 2 down on max range.