-

Posts

3,528 -

Joined

-

Last visited

-

Days Won

49

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by RFguy

-

some engines are good for no-lead, some are not. many have had no-lead suitable seats and guides fitted during overhauls in their 50 year life span.....

-

It is a good point about water freezing in the fuel lines, Nev. Fortunately, the Piper has good fuel sumps and I've never seen any water in them ever. (never say never ) . It's certainly always below 0 up there. Good point also about wing skins being cold. If I descended through a humid region, or cloud, that's something to consider. I still affirm for long pt to pt flying , flying low is TAS on the table. (FL125 is 123 kts TAS for 100 knots indicated which I can do) Interesting though what happens with the east west winds up there, going west, almost always better being down at say 8500 or 6500 with the headwinds. 8500 is a reasonable compromise. up high, bumps are less, radio coverage is better and options are better for engine trouble (unless u have a fire...) glen (PS: left tank always AVGAS and used for TO and landings, right tank ULP98 when available outbound)

-

Thinking about this, so many unknowns what is the existing intercom type and how has it been wired to the radio ?

-

Mike are you sure you just didnt leave it in the seat back pocket?

-

I wonder if a pre-built / wired harness is something that should be considered. there really isnt much to it. Otherwise labour costs in plane are not insignificant. Shajen, you can ground run the jabiru, just watch the CHTs. Don't let them get over 150C on ground . If the idle is set correctly, there is no problem ground running most Jabirus, but it wont charge the battery at that RPM. Do you have CHTs on all cylinders? If not, forget flying a Jabiru until you do.....

-

using the internal trig two place intercom ??? wired up the headset wiring correctly? not using shorting jacks ? "radio guys" ALWAYS sit in the plane with them running , up to full RPM and see how it goes... OK overall sounds mainly like a connection problem to the headsets, or some issue with the way the headsets are wired Please post a diagram of how it was wired in the aircraft IE as built. If you do not get this, do not pay the radio guy. glen

-

Hi Nev and I have learned this.... I knew it might be a problem, ffrom calcs - and so it was.... and it was a warm day.... The math said it would be a problem somewhere over 11,500' PA, and it was when > FL120.... at a PA of 12,000 feet, the air pressure is 65 kPa, WELL within the MOGAS RVP seasonal range of 55 to 80 kPa...... (avg approx 65kPa at 35degC) AVGAS is 40-50. so, if the air pressure was the same as the 35degC RVP, it would not take much suction to get vapour. (noting that the RVP reduces substantially at lower temperatures lessening the issue as you pointed out Nev with cold soaked tanks) . Not seen any issue at all at FL115 so far. Note that some manufacturers have wider ranges of RVP of their unleaded petrol than others, for whatever reason. BP says 30 to 100 (20 deg C), Shell PULP98 55-80 (37.8C), United98 27-80 (20 deg C). here are a collection of datasheets. Probably a good reason to avoid leaving MOGAS lying around, also, since the suppliers increase the vapour pressure for winter. (dont use it in summer) Fuels, Safety Data Sheets, Suppliers - Dry Lakes Racers Australia WWW.DLRA.ORG.AU The official home page of the Dry Lakes Racers Australia

-

Don't forget high altitude vaporization of MOGAS not just hot weather. So, do consider the need for the boost pump.. AND consider large diameter fuel lines from tank to pump to reduce suction tension (low pressure) which will promote formation of vapourization bubbles for high vapour pressure fuels (MOGAS). Keen readers will be aware I calculated that MOGAS might get bubbles in the fuel lines once over 10,000 feet, depending on summer or winter gasoline, and sure enough at FL125 the other day, (actually climbing through 11400 feet (slowly ha ha ) - fuel pressure began fluctuating a little periodically (bubbles passing) and slight EGT variations. Switch over to AVGAS tank, no problem..... drop back to 8500, back to MOGAS tank, no problem.....

-

E-Props ...who has first hand experience with these

RFguy replied to eightyknots's topic in Engines and Props

And also consider an airplane pitched for a student might be different to for a seasoned pilot. That is to say, maybe do not pitch the prop too fine such that the student is having to continuously be concerned with the engine overspeeding when the primary objective is to learn to fly the aircraft. IE might be pitched for 5500 WOT best climb to give the student some breathing space (but leaves some performance on the table) -

E-Props ...who has first hand experience with these

RFguy replied to eightyknots's topic in Engines and Props

For something like the rotax , for a prop pitched for max rpm at best climb, we control climb RPM at WOT by pitching up the aircraft and slowing the aircraft down and prop RPM falls to within limits. Generally we do not fly at WOT when S&L , this would mean an overspeed. If you operate out of restricted ALAs, I would be pitching it for MAX RPM (5800) at best climb . That is what matters most when you need to clear the trees. You could also pitch for 5800 at best angle (usually slower) but might mean you overspeed at 75% cruise in S&L but that will depend on the airframe (drag behaviour) and the prop . IE how much faster cruise is. If you pitch for 5500 RPM at 75% S&L, you might be leaving some climb performance on the table , that depends on the difference between best climb and your 75% cruise speed. If there is not much of a difference, then pitching for best angle might still mean you dont overspeed at 75% S&L. BUT Different props will have different airspeed behaviour. -

but Mode S and ADSB are supposed to coexist (if your modeS doesnt have adsb , or are you saying your mode S transponder HAS adsb ? anyway, you can look for that hex code on the sites...

-

@pmccarthy What was the hex code of the skyecho ?

-

so... have.bottle with known good bladder quantity should be good for two full bladder pees. 3.5 h flight should be OK. but it is after breakfast.... outbound morning flight with coffee in the veins , 1.5 h in, peed into the converted aluminium gasket lidded water bottle. no problem. only ended up in 30 deg bank... (no autopilot) . no issue with juggling flying, holding the bottle and other things. I realised, for a male anyway, in a bucket seat, its actually quite hard to pee with control (start/stop flow from busting) and you get a low flow rate. just not the right position. needed to pee at the 3h mark. OK, fine, bottle getting a bit high but OK.. only peed a tiny bit on myself. needing some water, I remember reaching behind into my 'bucket of stuff and picking up the warm bottle and thinking - yeah nah then picked up the cold bottle. morning coffee , then on the way home, 0600 departure, 1st pee 1.5h in. then 2.5h in, 2nd pee the bottle started to overflow. ..... but I found , sitting down and after busting I could not stop the flow, peed all over my jeans and and pulled up underwear, soaked them. not high pressure spray though, since low flow in that position. funny. anyway, put lid on bottle and put behind me. alright, so then I left my jeans wide open, belt open to dry everything (cottons) off, it was very very dry at FL115. everything drys fairly quick, fortunately. I got down to 3000' above the AD , 10 minutes out, and decide to zip up my jeans and belt before circuit just in case I crash, and in the wreckage they find a guy with his zipper down and belt off- not a good look - I would not want to look like I had been a "distracted pilot" LOL. so takeaway, need a bottom with a quickly sloping neck because you cant point it down there easily, and a handle on the bottle so it can be easly held, at at least enough capacity such that the bottle can be horizontal and still have plenty of capacity and not flow out the neck when horizontal. Some of the chemists have the bed bottle, they look useful but are clear. something like this- IE operation horizontal is essential. or one of the pro bottles

-

actually helicopters with the single 4 contact plug, are NOT all the same there are two variants and they look quite similar... ... there is the U-174 / Nexus TP-120 plug. 'us nato' (diameter 7.1mm ) and a Type 671 plug 'euro nato' (diam 7.57mm) U174 is the most common. But I have found australian registered helicopers with the 671....

-

Has anyone got any funny stories of peeing mishaps while on a long leg ? I do. I will write it up shortly. was quite funny. lessons learned. (Cowra to Broken Hill and return) .

-

Mid-air collision at Caboolture - 28/07/2023

RFguy replied to onetrack's topic in Aircraft Incidents and Accidents

I'll not unusual for me to land (full stop) on the cross at my home aerodrome - Cowra (grass) WITH another landing for a full stop on the main at the other end which is about 1km from the RWY intersection....but ! that's with good radio comms, (IE it has been coordinated) and with other experienced (5000hour+) pilots of aircraft that I know personally . it's easy to pull up my plane 200m before the intersection on the grass-, and the other guy can pull up their plane 600m BEFORE the intersection , that's easy peasy- so I think horses for courses......the other pilot in the other plane knows the potential complications. I do not think it is hazardous unless BOTH of us have to go around..... which said situation would be highly unlikely. But I wouldnt do it somewhere I didnt know. Now if you add a third plane in there that hasnt got good comms and / or a complete handle on everything, then that becomes a hazard for sure. -

Yeah alright then. install the 520, and be deep anal with laboratory oil sample analysis etc to track the engine, oil thermostat cooler/bypass .. oversize the oil cooler... and ......be sure to get the prop setup nice and balanced (Mike you can borrow my prop balancer), and instrument the hell out of it !

-

OMG. I'll put the opinion straight for everyone LOL: (ROtax/Lyco) Rotax , I think is an engineering marvel. What lets it down is the variability of installation, probably because it is in so many experimental aircraft category, and thus variability in maintenance , and a lack of adherence to the ICA . Installation issues : - variation of installed cooling methods of radiator and cooler. Many installations I have seen are deficient in oil or water or both and would not meet the Rotax IM requirements. - variation of airflow over the cylinder bores The 914 and above - the IM specifies a baffle/ air flow guide over the cylinder bores to cool them. This is rarely fitted and I would expect is a non-zero importance for the 912ULS - IE it is required for some conditions and cowls even on a 100hp engine.. . - Inadequately plumbed oil system- I would be highly surprised if many installations, especially those on owner-build would meet the hose vaccuum test combo of the oil cooler/oil hose/oil tank system per the Rotax IM. - non adherence to rotax instructions to use a return line for fuel - incorrect prop loading (pitch too coarse) Leaving 'accepted' deficiencies of - lack of oil thermostat, use of car plug leads and crappy ignition modules, tendency for 912 to foul front plugs at low idle, lack of user understanding of RPM regions not to run the engine in, lack of fuel pressure readout, variation of carb heat implementation, The Lyco has no such issues primarily because certified airplanes have to meet the part91 requirements. I am sure that if Lycos were extensively used in lower end experimental aircraft, you'd find failure rates not dissimilar. But Lycos are usualyl not used in lower end of the aircraft , IE they are less likely to be in a light touch maintenance environment, -glen

-

Mid-air collision at Caboolture - 28/07/2023

RFguy replied to onetrack's topic in Aircraft Incidents and Accidents

my radio goes on just after engine start and oil pressure established... squelch test button pulled/pushed to verify I can hear the radio open squelch noise in the headset. (IE verify audio path). this should give me about 10 miles of inbound approach aircraft traffic or at least 7 minutes of traffic listening (IE situational awareness). ADSB (in+out) + tablet goes on about the same time . Set to 4 kts minimum (ADSB broadcast velocity threshold) so that equipped aircraft can see me taxiing. -

Some segments will want a high hp/lbs ratio - certainly in the LSA, that's prime. IE where the engine is an appreciable percentage of the AUW . And that's a place for the geared engine. Rotax has been successfull, because mostly, they are very reliable. I am surprised of any manufacturers targeting the low end / LSA market being not geared. Except for reaplcements- since airframes are usually built around some nose weight.

-

this thread has lost its way

-

well, I like to get off site because I can eat real food. There are excellent places to eat in town (walking from the uni) , and a good healthy supermarket also same. There is a big RV park for the show. You at can least cook your own food. Yeah an RV trip would be cool. try and get to the Dayton air museum. Allow two full days dawn to dusk. Or three if you like reading the plates in front of the exhibits,

-

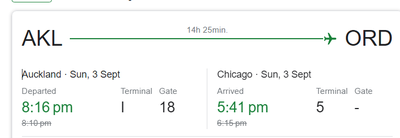

I do like that idea, avoids west coast. but you are definetly overnighting at Chicago, Although , SFO is pretty nice, that'd probably be my other choice. SYD-SFO or BNE-SFO. but I'd go the route that gets you on a 787. We did this time. great aircraft. I wonder is ANZ can book SYD_ORD via AKL ? I always fly United when I have an in-country domestic flight- because the codeshare with QF or VG is BS- they cant do anything for you to the desk. If you are on an american airline internally and international, they can pull all sorts of strings for you. AMercian airlines that codeshares with Qantas internally, they cant do anything with your tickets, moving you to a different earlier flight, etc, finding your bags- they dont have the IT integration like a all end to end airline. However, if one flies AKL-ORD, the poin tof entry is ORD, so that's not such an issue. You'll find appleton prices are in the stratosphere pretty quickly.

-

I used to ride the ski-doo every morning in skiing years. ROtax powered- Get on the ski-doo, -5deg C- straight to 100% UP the hill out of the valley for 3 minutes 100% from cold. oh boy. never blew up.