-

Posts

6,717 -

Joined

-

Last visited

-

Days Won

102

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by Kyle Communications

-

-

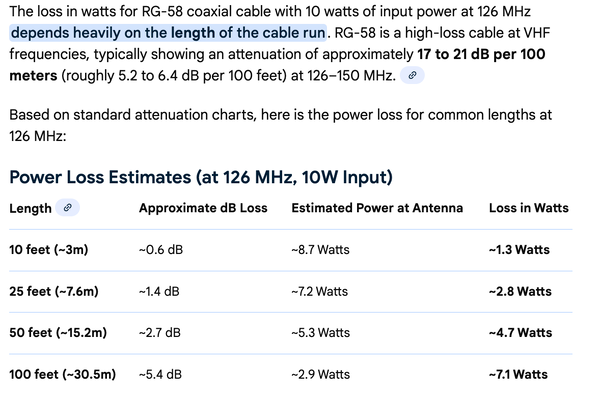

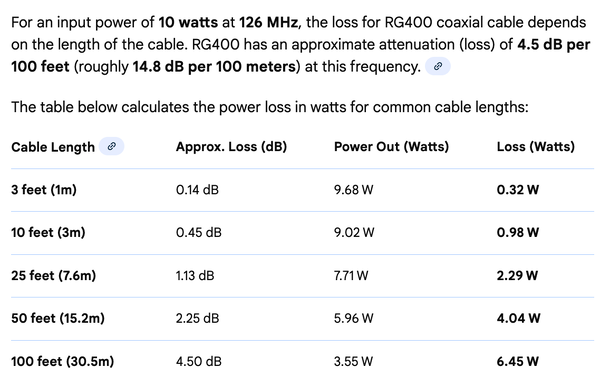

I just used AI but the figures are correct. 3dB loss is half so if your putting out 10 watts of power out of the radio then you are losing 5watts in transmit and half of the strength of the recived signal So it depends of course how long a run of coax you use. The shorter the better and every dB counts The cost difference is not a lot between both types. I know which one I will always use. Mark At 126 MHz (the aviation band), RG400 coaxial cable has an estimated signal loss (attenuation) of approximately 14.3 to 14.5 dB per 100 meters (roughly 4.4 to 4.5 dB per 100 feet). At 126 MHz (common for aviation communications), standard RG58 coaxial cable typically exhibits a signal loss (attenuation) of approximately 17.5 to 19.5 dB per 100 meters (roughly 5.3 to 6.0 dB per 100 feet).

-

RG59 is 75 ohm coax NOT 50 ohm. RG400 is what you need to be using. Its a double shielded teflon coax at 50 ohms. Less loss that RG58 which is 50 ohm coax.

-

I have known Trevor for about 50 years. First in RC modelling when a teenager. he has a hangar at YCAB and built the RV8. I have been flying it it but when he had a more sedate engine in it. Trev changed the engine out a couple of years ago with a much more powerful turbocharged suburu than what he had in it. It also had a constant speed 4 blabe prop. The plane was a weapon. He travelled regularly to Raglan to see Ron the owner as they were good friends. Trevor is a very strong person. We are all very upset by this and we hope like hell he can pull through. We are well aware of the odds of survival with the percentage amount of burns he has. As a signal of his strength to be that badly burned and also the chest and other physical injuries from the crash then to walk 2km back to the homestead shows just how determined and strong he can be. Trevor is a very experienced pilot and has flown a lot of different aircraft including WW1 Fokker Triplane and Sopwith Camels and many others. He has done a heap of first test flights on all sorts of aircraft. He can be a bit gungho at times but his experience in flying all sorts of aircraft and his skill can not be denied. The club at YCAB and all of his friends are praying that he does pull through of course. I looked at his track it seems he took off from Redcliffe on the 22nd and the accident took place on the 23rd at about 10am. We dont know for sure but pretty sure EFOTO most likely . The suuru would have been at full power and I would say it let go. There isnt a lot of options out of that strip but it is a very long strip. I think he has gone into the trees at the end and has walked all the way back to the homestead. I dont know anymore details yet. 11K views · 104 reactions | A pilot is fighting for life in the RBWH,... WWW.FACEBOOK.COM A pilot is fighting for life in the RBWH, after his plane crashed and exploded into flames in Central Queensland.

- 5 replies

-

- 16

-

-

-

-

-

Yes it does but make sure you connect to the right pads from where you took the connector off

-

No issues because the mini coax pcb connector I removed is a test connector that just uses a special test connector which will go to 50ohm input. It appears to be 50 ohm there as the performace basically doubled by going from the pcb antenna to a proper ADSB antenna. Thats a good test that the impedance is close. The coax was teflon 50 ohm and the tail connector is a BNC so everything maintains roughly 50 ohms. Coax lengths matter though at 1090mhz but it seems to work fine. The coax pcb connector was only so they could test the output of the chip It was basically a switch just a single pole single throw. The test connector pushed the contact away for the pcb antenna and connected the output of their chip to the test probe fitting and of course to their test equipment Mark

-

Forward slip with flaps extended? Savannah S

Kyle Communications replied to BC0979's topic in Savannah

Well in the Sav it doesnt really matter. I cant comment on other aircraft. The comment is for Savannah's not any other type. I have done it with flaps and without also with a lower flap setting which is available only to my aircraft or anyone who installed my modified flap bracket. Using full flap I cant comment on as I have never done it with full flaps on a savannah because I believe that flap setting is too agressive anyway. Thats why mine has 3 flap settings not just 2 -

Forward slip with flaps extended? Savannah S

Kyle Communications replied to BC0979's topic in Savannah

I love sideslipping in the sav. Flap or no flap really it doesnt matter. The sav does it really well. I do it all the time -

Queensland rocket launch does a Spacex

Kyle Communications replied to red750's topic in AUS/NZ General Discussion

They had a engine fail just after takeoff and also looks like another had lost thrust. I think every company who has tried to get their first orbital class rocket off the ground has had this type of failure. The one thing they took as being great was their thrust vertoring worked very well when the thrust was asymetric. Gilmore seemed pretty happy that at least it got off the pad -

-

Another NEW Savannah XL on its way

Kyle Communications replied to Kyle Communications's topic in Savannah

Bump -

I think Mike they need to be more forward in the airstream. Like they are they will act like a vacumm sucker and possibly draw fuel out there will be no positive pressure going into the tank.

-

Class 5 is not recognised by RAAus or even basic med is not recognised either. Only the drivers licence medical. The stall speed comes up which will allow more aircraft and NOT weight like we are limited to 600kg even though the aircraft can weigh much more. Under the current RAAus rules you cant fly a 720kg rated aircraft in the 600kg sport pilot category. This why my RANS S-21 has to go in group G or experimental in GA. Under Mosaic rules the RANS will be fine..a Cherokee or similar will be fine and you can fly it with a drivers licence medical. There are quite a few differences with MOSAIC

-

USB outlet to charge ipad

Kyle Communications replied to Keith W's topic in Instruments, Radios and Electronics

It maybe that the USB charger is toasted..they are not high quality if your paying 30 bucks..the aviation ones though are outrageous its like they just charge you 3 times what its worth because its avaiavtion. I should look at building a decent suppressed one. TI have a lot of chips for these now and also lots of application notes to use. I am sure there will be high quality ones -

USB outlet to charge ipad

Kyle Communications replied to Keith W's topic in Instruments, Radios and Electronics

As much as I have to say this buy a genuine cable..they are outrageously priced I know but they work. I was always having trouble with apple car play with generic leads...I bit the bullet aND BOUGHT THE GENUINE APPLE ONE AND THE PHONE CHARGES FAST AND APPLE CARPLAY WORKS ALMOST EVERY TIME...IT DOESNT WORK I BELIVE DUE TO THE HEAD UNIT IN THE TRITON..oops sorry for the caps wasnt watching while typing -

My Savannah S model rebuild Blog

Kyle Communications replied to Kyle Communications's topic in Savannah

I have a Galaxy GRS-600 they are all pretty much the same. I imported it myself direct from the factory. I hope to do the same with the chute that will go into the RANS S-21 but its a bigger chute and of course more expensive. The importing though is a whole new world of hurt but I found out after just by mistake how these parachute guys get them into the country with all the dangerous goods requirements. Supposed to get them repacked and rocket change every 6 years . If you have a certified aircraft then you have to comply of course but as a private builder I have far more latitude. I have done a lot of reseach on longevity and most are all fine for at least 10 years or more. Some have even been 20 years old and when let off for sh$ts and giggles they all seem to work fine. Just always need to keep an eye on the straps and connections to the frame Mark -

My Savannah S model rebuild Blog

Kyle Communications replied to Kyle Communications's topic in Savannah

Working on it now I have more time 🙂 -

My Savannah S model rebuild Blog

Kyle Communications replied to Kyle Communications's topic in Savannah

After a long hiatis I have finally been able to get back to work on Mabel. 20 months it has taken to get the subdivision done at our place and to be honest a lack of enthusiasm didnt help due to being too tired to do work on her at night after doing all the work around here we have done here. The parachute is now hooked up just have to finish off some final running the main strap out of the hole at the top. The seat bases are back in and the foam has been made and ready for upholstery for them to be done. They will velcro then to the seats that are std for a savannah. The tail feathers are on and cables run and ready for hookup. Wiring for the elevator trim is done,static is run up to the top of the fin also. I will bring the wings back from the hangar shortly and fit them. I will be adding some dihedral to these wings this time. I have 4 new sections of strut material so I have to cut and fit them then I have a bit of painting to get done. There are some cover strips that have to be painted and once the new struts are done they will have to be painted. The roof section has been covered in IR and heat film and it has been fitted. The windscreen is all fitted but out at the moment while I am working on it. Then once it goes it the base section will be sealed with black sikaflex..a special one I managed to source. It would be nice to get her flying by the end of this year 🙂. Also got to trial fit the mrs and myself in there today..she likes the new comfy seats- 714 replies

-

- 10

-

-

-

Actually warranty repair on anything there is NOT a requirement for the company to pay for the freight on your goods. The requirement is the company will totally fix/repair or replace the goods but the requirement is that you have to get it to them. This is the actual requirement by law here in OZ. If the manufacturer does offer to pay the freight for you to get it to them then thats a bonus. But the manufacturer will usually pay the freight back to you but you pay the freight to get it to them. That is how it was with our company when I was working for them. That was the government direction.

-

Jab 7252 we all know radios are pretty much all the same now internally but airband radios are "certified" that magic word for lots of paperwork crap that CASA and other govt depts seem to love. The issue of course is the Yaesu ham rigs and the other brands will toast the filters if used on the airbands with any sort of power if they have been modified to all band tx. Danny yes some radios are voltage sensitive and of course you should be using a good servicable battery.