-

Posts

1,213 -

Joined

-

Last visited

-

Days Won

20

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by KRviator

-

Vans Aircraft suffering cash flow difficulties

KRviator replied to rodgerc's topic in Aircraft General Discussion

True, but in defence of the RV's, once you've actually built the thing, there's very little difference in operating costs vs a Jab if you were to compare them side by side. A bit different if you have to pay a LAME to maintain it though. For example: I use 25LPH for 140KTAS, or 9.73L/100km. The J160 uses 14.3 to get 100KTAS or 7.72L/100km. Much better efficiency granted, but at 30% slower speed and a lot less payload, so you're spending less on fuel, yes, but your other costs, oil changes, engine hours and other lifed components are reaching their limits earlier given the same flight profile. My last decent flight was up to Gladstone & Townsville return, total of 13.5 hours in the RV but would have taken 17.6 in a J160. 337.5L of fuel in the RV, or 251.7L in a Jab would give an 85.8L difference at about $2/L, so call it $170 cost saving in fuel alone, but at the expense of 4.1 extra engine and airframe hours. With the -9, I simply fly for the cost of fuel, oil, filters and plugs. I don't have an engine overhaul budget, or an avionics upgrade budget so the hourly cost is around the $70 mark. Or $120 if you include insurance - though I don't for the same reason I don't have an hourly cost for our 4WD or caravan or boat that includes insurance. It's just another bill to pay. -

Vans Aircraft suffering cash flow difficulties

KRviator replied to rodgerc's topic in Aircraft General Discussion

AIUI, it's not technically bankruptcy but bankruptcy protection while they restructure - ie, the debts Vans currently owe to the likes of Lycoming and Stein cannot be enforced while under Chapter 11. If the court and creditors vote to approve the restructure, then they move on with the approved pathway. If the creditors vote to not approve the proposals, only then could Vans actually be declared bankrupt. I don't see that happening. Vans is an immensely popular kit supplier, for the reasons I posted above. To enforce bankruptcy on them would hurt the creditors many times over through lost sales triggered by builders purchasing a kit and needing an engine (Lycoming) or avionics (Stein) or even the metalwork for engine mounts and things. Even copping a loss of 50c in the dollar for each and every creditor supplier- they'll make that back and more with the higher kit prices and ongoing operations than winding up the company. Of course, that may not necessarily help the builders who could lose out in such a scenario. As it is, they're looking at a 30% increase if they want to proceed with their kit purchases. As I posted over on VAF, I would encourage builders to cop that pineapple, but recoup it down the track by purchasing a used engine or prop, or installing simpler avionics, in order to come out the end of the process at the same "overall" cost, and still have a flying RV. Otherwise, you won't have an aeroplane and you'll still be out those $$$. -

Agreed. As an owner, however. As a builder or prospective builder, I think they're going to have to pay a significant premium going forwards. I see on VAF that Van himself has stumped up several million dollars to provide interim funding for Vans to continue, so if a private individual, even The Man himself, is prepared to do that, I can't see RV's going the way of the dodo. Still, it must be heart-breaking for him to see Vans in the position it is now, when his name is on the building.

-

Wow. I knew they were in strife, but bloody hell. On the plus side, most companies do make it out of Chapter 11, and I don't have the slightest doubt that Vans will as well, simply because there are not many comparable products to the RV lineup. Of course a big part of their appeal was they were relatively affordable, but that's certainly going to change going forwards, especially with the exchange rate being what it is now, too... Sucks if you were waiting on a kit in the near future, I have a feeling the pineapple you're about to receive won't be lubed...

-

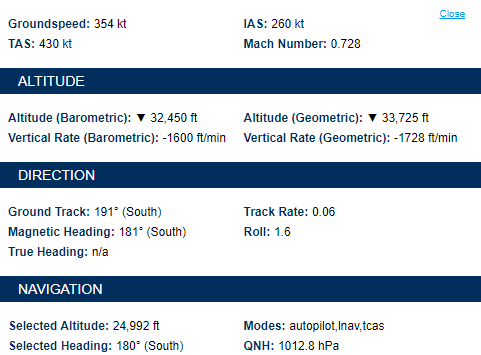

True if you don't have access to the ES downlink, but @flying dog specifically referenced KIAS, which suggests he can read the downlinked IAS. Here's a screegrab from my FlightAware SkyAware tracker showing what's being received from a Dreamliner coming into Sydney right now, so you can receive both KIAS, KTAS and GS if you have the right gear, but if you simply use the public sites, you probably won't see the rest of the ADS-B squit beyond just GS. To answer the question, 250KIAS is the limit unless higher is operationally required. You'll find heavy jets, particularly 747, 777 & Airbus (what's the plural for a group of A380's? A problem? Airbii? 😕) have green-dot (minimum drag / best L/D) speeds above 250, and as such often "request high-speed climb" which ATC can, and routinely do, approve. For the A330, it's calculated at Weight(t) x 0.6 + 107Kts, so 230T = 245KIAS. That A340 that went 4WD'ing at Melbourne had an (incorrectly calculated) GDOT speed of 265KIAS, for example, so after retracting the flaps, that's what the crew would want to climb at. In the absence of approval to exceed 250KIAS, then that remains the default limit to transition altitude. I'll try to dig up an AIP reference later today.

-

Leighton Beach WA light aircraft ditched 20.04.2023

KRviator replied to trailer's topic in Aircraft Incidents and Accidents

As I posted over in 'Prune, I takeoff and climb on one tank, swap to the other and run that tank dry, and only then do I change back to my original tank. Two tank changes total for any long-range flight. Lateral trim isn't a huge issue with the -9 compared to other aircraft. This way, I know I have used every drop of fuel out of that tank, I'm not fluffing about or forgetting to change at the 30 minute mark, and every remaining drop of usable fuel is in one tank come landing. -

WAAS enabled GPS for 24mth altimeter check

KRviator replied to Philster2001's topic in Instruments, Radios and Electronics

Can't imagine it's useful to use GPS, as that's altitude above the theoretically perfect GPS ellipsoid, not AMSL. You're better off using a water manometer. Cheap, easy and can do it in the hangar for the cost of tubing and a few minutes on Google to print a suitable height to altitude chart. -

From personal experience with my RV, don't be in so much of a rush to the finish line you stumble at the last hurdle... First flight seems "so close" but I still missed bleedin' obvious things I should have picked up on...

-

The sooner this comes in, the better, but I don't know if it'll be any benefit to yours truly... I have a newly-diagnosed, but very minor medical issue I disclosed in my last C2 a couple months back. Unless I told you, you'd never know about it. 8 weeks later, several phone calls to AvMed after the 4 week ETA passed, the application being marked as "urgent", the DAME2 himself recommending the issuance of the medical and I'm still waiting. The sad thing is, I also drive some of the biggest trains on the planet and the last rail medical I did I went in with exactly the same paperwork I had for the DAME, and walked out 2 hours later with my rail Cat 1 in hand, including ECG and all the rest. That medical isn't specific to my employer or anything, it carries across like a Class 1/2, so I could get a job driving the XPT with no co-driver, with 400 POB at 100 miles an hour. But here we are, 2 months after I did my aviation medical and CAsA are still sucking their thumbs while the RV's parked up in the hangar gathering dust.

-

4.11.23 Cloncurry light plane crash

KRviator replied to trailer's topic in Aircraft Incidents and Accidents

That first descent had me wondering too, but -HPY had the same vertical profile in a very similar geographic area a week earlier on a TWB-ISA flight, so it was intentional both times. Once we could be forgiven for linking it to the accident, but not twice. Here's the accident flight: And here's a week earlier - same area, same descent, albeit not quite as quick. -

The Foam Company has it (and online prices too!), address seems to be Archerfield, but they say "may be dispatched from multiple warehouses in Bris-Vegas"

-

why have there been so many accidents this year

KRviator replied to BrendAn's topic in Aircraft Incidents and Accidents

Is the speed warning in the car based on a database, or the last-passed sign? Either way, the car's wrong. There's two 'standard' limits, one being 50k's in a built up area, the other, 100k's for outside a builtup area. NSW Road Rule 25 is the reference. You can go faster now! 😉 -

why have there been so many accidents this year

KRviator replied to BrendAn's topic in Aircraft Incidents and Accidents

Only in a "Built up area" though- and that is defined as "where there are streetlights or buildings spaced closer than 100m for at least 500m". IF there's no streetlights / buildings and no lower speedboard then the generic limit of 100kph applies. -

why have there been so many accidents this year

KRviator replied to BrendAn's topic in Aircraft Incidents and Accidents

Be careful with ascribing "Country roads" to "Country districts". I dare say it's the same in SA and Mexico, but in NSW, a "Country Road" is 𝙀𝙑𝙀𝙍𝙔 𝙧𝙤𝙖𝙙 in NSW outside the LGA's of Newcastle, Lake Macquarie, Wollongong and Shellharbour, and those in metropolitan Sydney. F3 at Gosford? Yep, a "Country Road". M1 at Raymond Terrace? Still a "Country Road". New England Highway at Thornton? You guessed it - a "Country Road" as well. It ain't always what a reasonable person would consider "country"... -

Personally, I can't see Van's going anywhere - they offer something no one else does, a (relatively) affordable Meccano set that can take you from Brisbane to Townsville in 4 hours that you can build in your back shed. When I brought the engine for my -9, the dollar was pretty much at parity with the USD, and the entire cost was $30,000 including GST & shipping. For a factory-new engine. The current price for a new O-320 from Vans is now $39,150USD or $62,000. Plus shipping, plus GST and you're upto well over $70K for an engine, or more than double what I paid. IF you want an RV going forwards, unless you can already afford to buy a Cirrus, you might have to be content with a standard kit, a well and truly used engine and basic VFR instruments...

-

Here's two great examples - and I mean no disrespect to the sellers - if someone actually wants to pay such big bikkies, take their money! VH-SMJ, a rather nice Comanche was sold in November 2020 for $139,000. Two years later, it's for sale again. For $225,000! A 62% increase in two and a smidge years. Could be why it hasn't sold for the many months it's been listed... VH-VVT a Turbo 210 sold a couple of months ago for $119,000. It's now listed for sale for $165,000 A 33% increase in 12 weeks! And apart from having its' annual inspection done, from what I can see, there's been nothing else completed - according to the logs, it hasn't flown in nearly two years and only 15 the year before- that's what put me off it, along with the engine being beyond TBO. If it was being regularly flown, she'd probably still be decently priced, but not at $165K! Coupled with the Van's issues, you might see RV prices on the up and up too in the year ahead... Realestate? Pfft. Invest in a plane!

-

Vans Aircraft suffering cash flow difficulties

KRviator replied to rodgerc's topic in Aircraft General Discussion

I think that's a bit rough - for many, many years Vans has had their QB's assembled in (from memory) the Philippines- including mine! AIUI, they then started a new partnership with someone in South America, and I believe (but am not positive) that that is where the primer issue came from - not their long-established Asian partner. Apart from a few rivets that were a right prick to do when installing a canopy bracket after the fact that, IMHO, should have been done as part of the QB assembly, there's been little-to-no issues until the QB-primer one reared its' head. Again, that's a bit rough. The difference between "Standard" and "QB" kits for the RV's was (at the time I built) around $5,000USD - it's now about $9,000 - and it is worth every cent of that differential. The Phillipines guys doing it do it day in, day out, and do a very good job. The simple fact is Van's couldn't expand at the rate they needed. The RV's are very popular kits - witness the 18month-2 year lead time for the QB kits before Covid came along. Word of mouth is a very powerful selling agent and the RV's perform pretty much exactly as the brochure says, so the word went out. Vans has traditionally punched their kits, including to final-size on the later ones. But with the growth in business, they couldn't get enough throughput, fast enough, so they contracted with a third party to laser-cut some parts. For whatever reason, this provider modified the toolpath for the laser such that it resulted in slightly out holes, as well as spatter on the parts, as well as the aluminium now becoming prone to cracking while riveting due to the heat-affected zone caused by the laser. Now, the occasional bad rivet is acceptable - I have a half dozen flying in my RV now that'd I'd probably goober-up trying to fix so I leave them there as a reminder that I built this in my back shed - but builders were finding a lot of small cracks in a lot of rivets and they weren't happy campers, and rightfully so. Until this issue, no one knew Vans was laser-cutting parts. What's got me stuffed in this whole thing is not that Vans did it, I can certainly understand why they did! But that they have apparently zero recourse against the two companies involved - for the bad toolpaths at least (probably not so much for the cracking from the laser as that's something Vans' should have detected earlier) but especially the primer issue. That's something I would have thought either the supplier would have to make good on, or their insurer. -

Only if they have an electrical system capable of powering it... Tigger Moth or a Chippy without an alternator = NORDO to the great race...

-

I don't read it that way. A VH- registered Tiger Moth, no radio, no transponder, can fly in without speaking to anyone, as could a VH- registered Jabarooooo (but not a RAAus registered one). But RAAus with VHF comm, GNSS and ADS-B can't come. There's no mandatory communication requirements, bar IFR on a separate frequency and cancel your SARWATCH via phone, so there's no clearance into the active R area provided. Which makes a mockery of the whole process, but again, this is airspace in Australia. Sometimes I wonder why we bother...

-

Right here, chapter 2.1: Furthermore, permission to operate within R960 is not required! (So long as you're VH- or an international visitor), as per Chapter 3.2: Too bad if you wanted to fly out there in your Jab or Tecnam...

-

Second close call for Melbourne Airport

KRviator replied to red750's topic in Aircraft Incidents and Accidents

Perfectly safe if the crew RTFNotam and apply the correct TODA in their performance calculations. In this case, I'd wager they didn't, for whatever reason and they're going to be in for tea, no bikkies with the CP... Our back yard is at the end of the local runway, such that if someone undershoots, or fails to get airborne the other way, the kids are gonna get a new cubby house. We've been mowing, doing earthworks and just flogging around on motorbikes with planes upto and including Falcon 8's and Herc's passing 100' over our heads and don't feel unsafe in the slightest. -

Need to have Ian change the title to NOT stolen SkyEcho! 😛

-

SCAT is (usually) good depending on exact type. SCEET is bad. That's the one that has a lining in it to reduce turbulence, however, this lining can come adrift when used in negative pressure situations, such as induction tubing. Some SCAT hoses can also have the outer lining deteriorate between the wire helix and ingest that too, so it pays to keep an eye on it if its' used as part of your induction system. Here's a good writeup from FSA in years gone by, incidentally discussing a Gazelle. I remembered it, but CASA's ruined the FSA website, so had to grab it from Wayback... The Wrong Part

-

So, a quick followup. I ultimately decided to fly to Donnington Airpark and don't regret it for an instant. Was met on arrival by Christian, one of the owners, got an open hangar for the 2 nights, and driven into and picked up from our accommodation in Townsville. The 'taxi' service was $50 each way, and $10/night for a hangar, IIRC, $10 landing fee, for $130 all up - and I reckon that'd be about half of what I'd have been charged for YBTL and an Uber to our hotel from the big airport.... The runway was beautifully kept short grass, and about 900m long, albeit with a bit of shear on final from the easterly breeze. Unless you have to fly into Garbutt, keep Donnington in your back pocket - I'll definitely be going there again.

-

Defect in Vans laser cut parts

KRviator replied to danny_galaga's topic in Aircraft General Discussion

There's quite a long discussion on VAF about these LC parts, and the angst it's causing builders. My concern, FWIW, would be even if Vans comes out and says "WE've determined there's no issue if these LC parts are in X-Y & Z structures, build on", the known cracking, even if it isn't an issue structurally will lower the resale value of aircraft so fitted, in the same vein as the 3L Patrols compared to their 4.2 Brethren...I paid for a kit that "won't crack", I expect to get a kit that "won't crack". Not "It'll likely crack, but we've determined it'll still be OK". Granted, even my pre-LC-debacle kit will likely have a few hairline cracks around the occasional dimple, it isn't every dimple, or rivet.