-

Posts

902 -

Joined

-

Last visited

-

Days Won

35

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by Moneybox

-

Left at 7:00 for Coodardy. The iPad was fully charged last night and on about 60% this morning. After landing a realised I didn't bring a chair. Then I grabbed the iPad and settled down on the ground with the ants and my iPad, it was dead flat. No book to read and an hour to spend filling the 1000L IBC's. Fortunately I watched where I was going on the way out because the old iPhone 6 is not too smart on OzRunways.

-

I spoke to Skippy today and so far he's quite happy. Yes Ducati have dodgy rectifiers however if what I read is correct there are problems with the solder joints that can be rectified if you wish to dig the resin out of the back side. My guess is the Chinese are better with a soldering iron than the Italians. They'll either have a 10 year old kid or a robot doing the job.

-

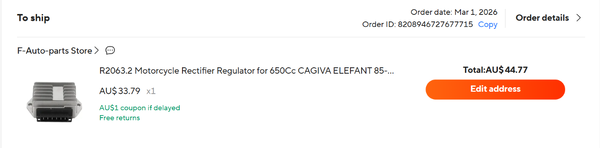

Sorry guys, visitors arrived and stayed all evening so time got away. Description report New high quality products. Easy install and durable use. Great quality and great Fitment. Correct Connector No cutting or splicing. Give a sharper and more sophisiticated look for your car Applicable: for APRILIA 8112200, 8138004, 8212120, AP8112331 for BENELLI 51721400 for CAGIVA 037038500, 061546750, 080546458, 42901, 4851000, 54040011A, 800054017 for DEUTZ 04191201, 04191231EC for DUCATI 061046750, 061946750, 343520 for GILERA 316788 for LOMBARDINI 7362.018, 7362.022, 7362.027, 7362.040, 7362.056, 7362.66 Colour:silver Material:Metal Package Contents: 1x Rectifier Only the above package content, other products are not included. Note: Light reflection and different displays may cause the color of the item in the picture a little different from the real thing. The measurement allowed error is +/- 1-3cm. Will it do the job? I don't know but it's stated to be suitable for several Ducati models. I'm not into bikes so I don't know one model from the next and I wouldn't have done this if the Rotax rectifier was a good product, it's obviously not. This is not a critical part so considering the price and ease of installation I think it's worth the test. I need to set up a method of monitoring battery voltage. A simple digital volt meter will do and I'd like to see something indicating the Master is switched on. The only indication I have at the moment is the sound of the Hobs meter ticking over. I know there are a lot of previously tested rectifiers but all needed wiring modifications and all come at a price so close to the original part I may as well buy the original. Lets just see how it pans out.

-

Now you can call me a tight-arse if you like but the Italian part is certainly not reliable. Lets see what the Chinese can do. It should mount on the same screws and directly plug into the harness.

-

I tried to stay away from tiger country, saw a few water buffalo and rhino but no tigers out here. The old iPhone looking through the canopy into the haze didn't do too well. I appreciated the modern facilities at Paynes Find although the door was locked.

-

I started out with a full tank, dripping out the lip. Did a few circuits that included two touch&go's and two landings in 0.7hrs. Then I flew 1.9hrs including runnup. Next leg was 1.5hrs including stuffing around with the battery and I added 20L of 98. I've just added 40L to fill up. That's 4.1hrs on the clock for 60L of fuel travelling on 5000 to 5200rpm and the first 1.9hrs at 4500' and 1.5hrs 6500'. Approximately 275nm travelled. It looks slow but I spent quite a while on runup before circuits, trying to sort the battery and runup before leaving on the first leg.

-

Ok guys, your attempt to assist has been helpful although you caused me way too much stress for a Sunday morning. I followed the instructions, resistance in the stator was fine at 0.1 ohms and the wiring and terminals look good. The battery charged up nicely, I forgot to give it a load test before installing it but I'm not concerned about the condition of the battery. All went well until I couldn't get any AC voltage from the alternator. I even tried willing it to work because I really don't want to start digging into the back of the Rotax. Eventually I worked out I had to press a Select switch on the multimeter to change from DC to AC and my blood pressure dropped about the same as the voltage came up. I got 19v at a high idle and 22v at 3000rpm so now I'm happy. 🙃 Now I just need to buy a regulator/rectifier and a capacitor. It looks like the Rotax rectifier is going to come in at something over $300 plus the capacitor and is known to be unreliable. Then I have to option of fitting one of a Japanese machine, most likely made in China but likely to last a lifetime for $50. What a tough decision?

-

Great article Skippy. That capacitor looks like a must-fit item because the rectifier certainly has a short life expectancy. Blueadventures suggested I might keep a spare rectifier so I'll order one right away and after a few checks most likely fit the new one anyway. If I'm to keep a spare it can be a used one if it still operates. If I had a 19 rego I'd be fitting one of the aftermarket options, preferably something not made in Europe.

-

I can carry out a load test once charged however that is not going to fix the alternator/charging problem. I have no doubt the battery may have lost some of its ability to supply a full discharge however it did fully charge after it was flattened. After I'd left the master on and found the battery flat it was fully charged. I left it at the door of Northam Air Services with a note requesting to have it charged. I picked it up a month or so later and it cranked the engine as if fully charged, not the sign of a stuffed battery.

-

There's no way of telling if the generator/alternator ever worked since I got the plane. It hasn't been used enough to tell and the generator light operates as if it's charging.

-

Yes I understand the battery may now be damaged however this is not a battery fault. I have no generator charge. I bought the battery new so about a year old but until completely flattened over several days it remained fully charged. It recharged fully after that so I'm hopeful the battery is ok. It may even improve with constant use.

-

Did that 9.8v same as battery voltage.

-

The plane has no volt meter or amp meter. I've checked it with the multimeter.

-

No, slight voltage decrease.

-

I planned on filling the tank as soon as I landed. I went down to the card operated bowser, the only 98 in town but it's out of order. It's already been reported but being out here repair might take some time. I do have 60L of fuel I changed out a month or two back, I could mix it with the half tank left.

-

Yes, I just came in from checking it out. 10v in the battery so I started it with the jumpstarter. The red generator light comes on with ignition as expected and goes out once started but there's absolutely no battery charge. 9.8v at 3000rpm.

-

Can somebody tell me how much charge I get from the 912 ULS alternator? How does that compare to the current drain to charge an iPhone 12 and a iPad series 6? I started out with a flat battery. My nice new Odyssey battery might be stuffed since I left the Master on a few weeks back. It's been charged and flown since but after standing for a couple of weeks it was too flat to crank. I took it out and put it on 6A charge for a few hours before putting it back in knowing it was not fully charged but I need to fly while the weather was in my favour and I expected the Rotax to charge it. This morning it fired up ok but after landing over 2 hrs flying when I stopped to refuel it was too flat to crank again. I'm charging the iPad and iPhone while I fly. I managed to reach up through the bottom hole on the cowl and attach a jumpstarter and flew off for another hour. Mid way the tacho shut down so I pulled the cigarette lighter plug and the tacho came good until the iPad dropped dead and I still had a long way to go so I plugged it back in. Once again the tacho dropped out so I continued on without it. I've only just arrived home so I haven't had a chance to put a meter on it but the charge light says the Rotax is charging.

-

I've just been in the air for a little over 3hrs and to be honest I could have done without a Manifold Pressure gauge. I used the variable pitch prop to avoid excessively high engine revs and I backed the throttle off by about a third to unload the engine. I can here the revs getting up into the yellow and I can hear it working unnecessarily hard. Variations in manifold pressure were next to nothing. I can't see the value in it.

-

Great document Skippy and I've worked out how reading it makes you engine last longer. The hours spent on reading are taking you away from flying therefore your engine lasts longer. 😀

-

My brother bought a 1970 Mazda Capella new, took it back for the first free service and never removed the drain plug after that. It lived for nearly 200,000km before it was sold. He said he saved a fortune on service costs.

-

If you just drive to the pub and back you should change your oil more often.

-

Hi Guys, help me out here. I've never had a manifold pressure gauge. I understand how it operates and I understand what it's reading but I don't know my best settings. When I'm cruising I have to adjust my propeller to a high pitch to prevent the engine running over maximum revs. What I don't understand is where my best/least fuel consumption comes from when matching RPM to Manifold Pressure while maintaining cruising speed. Lets say I want to keep the Rotax 912ULS spinning at 5000 revs while getting my best economical cruise speed. Do I control this with manifold pressure?

-

As long as it hasn’t been over tightened before you’ll most likely be able to reuse it. If you can’t get you hands on one and it’s solid metal it could be annealed and reused. My experience with purchasing Rotax parts is you could save a few bucks by buying an assortment box of sump plug washers from your local automotive part supply. If the washer has a neoprene seal inserted then a hydraulic parts supplier should have one.

-

Perhaps we just need to all have ADSB/Out? https://www.flightradar24.com/blog/inside-flightradar24/flightradar24-expands-global-coverage-with-aireon-space-based-ads-b-data/?utm_campaign=website&utm_medium=email&utm_source=sendgrid.com

-

Skippy, I’ve just finished telling Mrs Moneybox that I need the 4 seater you talk about. We don’t get to go shopping very often so the list gets longer every day, I leave in the morning. OzRunways says I can go all the way on my 65L tank but I’ve got an extra 30 that will go in halfway home. I’m yet to work out the Sportstar’s range.