-

Posts

5,115 -

Joined

-

Last visited

-

Days Won

184

Content Type

Profiles

Forums

Gallery

Downloads

Blogs

Events

Store

Aircraft

Resources

Tutorials

Articles

Classifieds

Movies

Books

Community Map

Quizzes

Videos Directory

Everything posted by bexrbetter

-

Really? I've had a couple of posts edited, and one removed recently, was pretty much called a racist also, for factually explaining how some immigrants were using methods to get residential visas. In the Alan Joyce thread someone said "I wonder if Qantas gave him a big gift" and I quipped "His husband would give him a big gift" - it was removed. It was a joke, and typical Australian conversational humour at that. Why the completely irrelevant off topic about someone's marriage was even allowed to run ..... Thing is previously we could discuss things here, not racist things, but factual things, it was one of the few forums left you could express yourself. And of course hand in hand with that, you removed Off Topic because a few members forced themselves pain by continually open threads who's content they were well aware of. Yes, some threads went too far previously, but now you seem to be compensating in the opposite direction. Then you've got the insidious rat Flying Tornado who has been running around for years giving everyone the shites. Do the Facebook thing and when I ignore him he can't see what I post either. I mentioned that in 'Site Problems' but no reply, but a laughing emojie appeared, by guess who ..

-

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

Some more lower stringers in today, as well as corner gussets .. A person was kind enough to suggest I run out and buy a cheap junk battery drill for de-burring, because they are weak and slow, ideal for the job ... and he was right, the drill bit is even heavier than the drill! I'll get a better bit later for it, or cut the drill bit down. Funny how you just get into a habit of doing things one way for decades, when there's better alternatives. -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

But anyway, back to the task in hand. Only had an hour to spare today, but got to trial the very first parts ... -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

"All" Marty? "ALL" did you say Marty? While it can help to pass the time away while eating breakfast, the sides of Corn Flakes boxes are not actually a reliable source of information. Putting "LSA" aside just for a moment, a company called Cessna, the largest light aircraft manufacturer in history, does not use 6061, they use 2024T3. Vans, who is actually the largest LSA manufacturer, by far with the RV12, don't use 6061 either, they go for the 2024T3 as well. Not to mention all their other top selling models that put them behind Cessna as number 2 light aircraft manufacturer. Then there's Gruman who's first light aircraft had 6061, but they went to 2024 on the next model. Then there's Piper, Rans, .... quite a long list of light aircraft manufacturers who don't use 6061. Oh, Zenith LSA low wings used 6061 ..... and their wings fell off. Mind you a number of Vans RV3 2024 wings fell off too. Again we come back to engineering with the material, far more important, relative, than the material itself. As for 7075, well Airbus, Boeing, huge numbers of military aircraft all use 7075 in their wings extensively, especially spars and top wing skins, because it's outstanding strength in compression that you need for a wing, it comes no better than 7075 and it's derivatives. .. But hey, above all, one thing I have learnt over the last 20 years on the internet (I joined my first forum in 1999), is that you can not beat the Internet and social media with actual facts. If 2 Members here pop their heads up and say that 7075 is bad, then there's plenty of others out there with the same thoughts spinning through their heads. Due to that sole "Internet" factor after reading Marty's comment, I changed my order to 2024T3 this arvo. So now I am protected by Cessna, Vans, Piper and many other famous light aircraft companies usage of that spec material, a clear case of social media triumphing over actual engineering. ..... not the first time, certainly far from the last. -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

You could say the same for Carbon Fiber too, and yet numerous craft out their with carbon wings/spars. 7075 has 3 times the strength, 3 times the elongation of CF, and most importantly for a wing and spar, massively stronger in compression than CF (all composites are weak in compression), one of the critical factors for material choice in a wing/spar - yet plenty of successful CF winged planes flying, just as there is plenty of highly successful planes flying with 7075T6 wings and spars. The reason: It's called "Engineering", and I assure you I am over-engineered in this area, I am paranoid about 2 things: Wing failure and roll over protection. I can show you 6061 spars that have failed, I can show you wooden spars that have failed, I can show you 2024 spars that have failed ... and I mean under normal conditions. They won't be handling it, spars will be complete. There's other safety measures in place, but when we get there .. -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

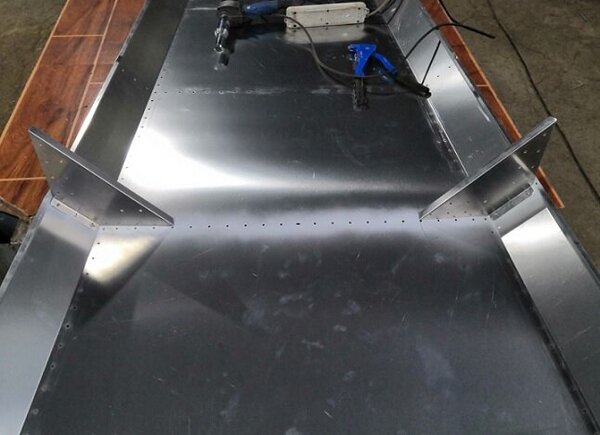

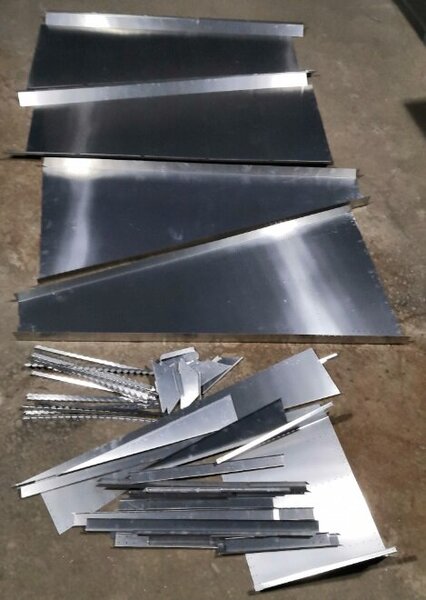

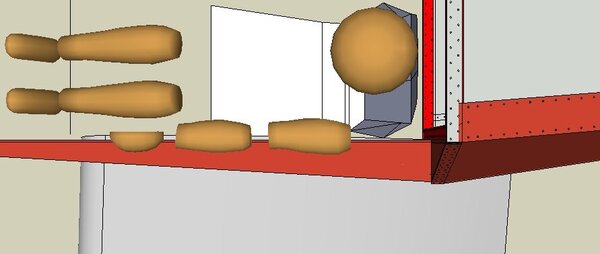

Fold shop today .. The Boys at it .. The result .. Dunnya just love pre-matched holes .. Trial fitted the "Bex Rib-Fit System" now patented in Nigeria (got a great deal from some Prince there) The silver speckly stuff is oil based paint, I think it's a good enough anti-corrosion joint sealant. Silver speckly because it's what I had. Oh, and I bit the bullet today and ordered some 7075T6 for wing and HS spars. "Ouch" said my wallet, it ain't cheap, but cheaper than the Titanium I wanted to use, and much cheaper than Carbon Fiber, but fact is I wouldn't know what I was doing with Carbon Fiber anyway, so moot point.. So tomorrow will be a few thousands twists of a drill bit by hand to de-burr, and some trial fit-ups. -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

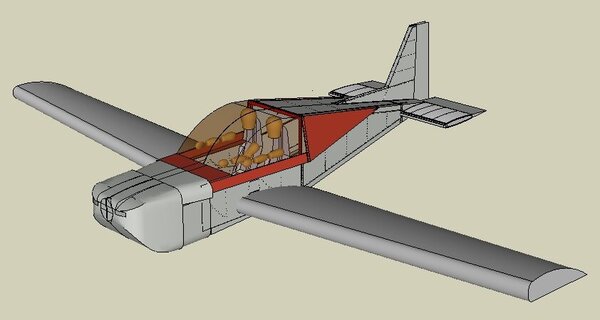

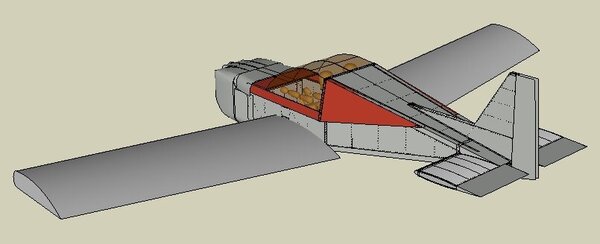

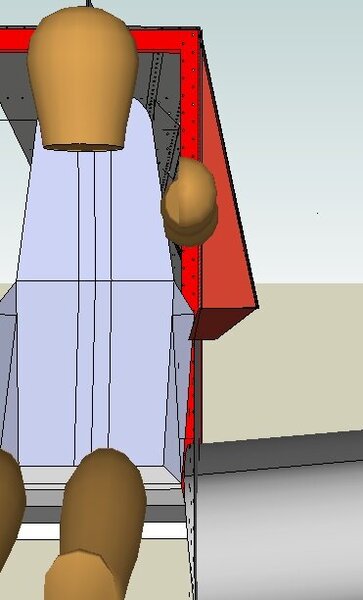

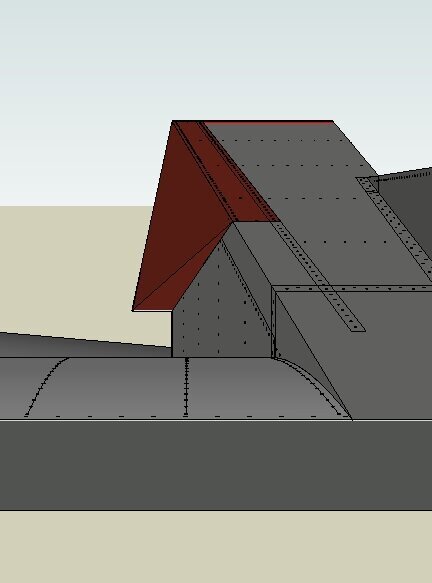

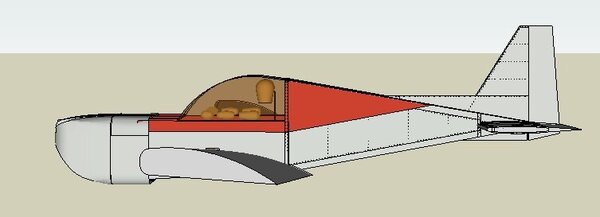

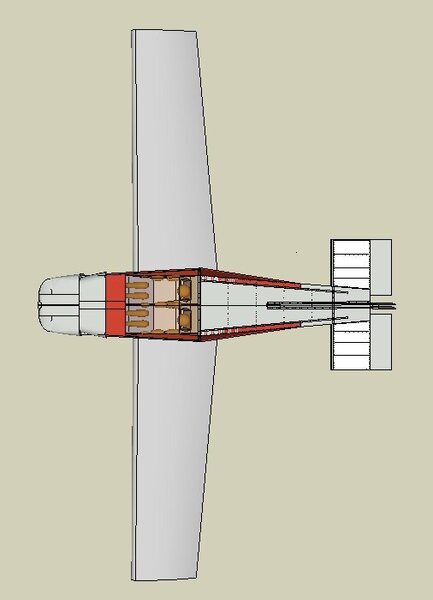

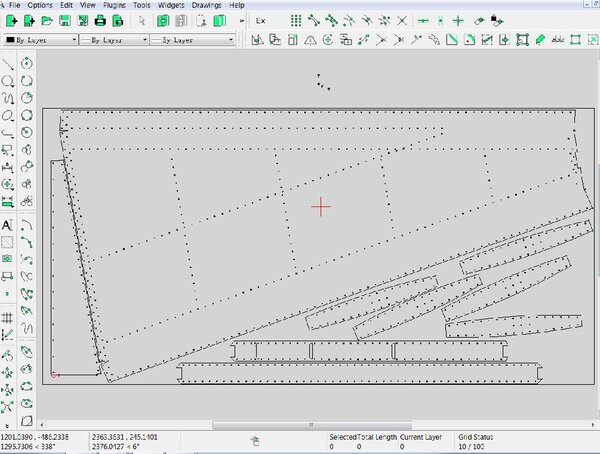

Fin/VS is 'slab' sided, but LE is of course aero rounded, TE is 'tapered to a point' rudder. Later there will be a slight curvature to the sides of the Fin/VS, but first i wanted to make the part to see how much curvature I could force on it with the 90 degree flange on the bottom. Not everything is shown on the 3D, not everything shown is how it's going to be exactly. The 3D CAD to me is merely a measuring tool, and a very accurate one, as you well know. I actually came back to add an edit but the edit function had timed out (too short a time here Admin) It read.... PS: Graphics are crappy, if you want better, go join a computer CAD group, but for those who want to see a real plane get built, watch this space ... -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

I'm almost ready to jump in and make engine noises! Look at all those lovely pre-matched holes ... ...off to the fold shop tomorrow. . -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

So Guys, let me introduce to "Bob". Bob is as simple a plane I could figure from all my experiments and investigations over the last number of years. Simplicity, cheap to produce, cheap and very fast to build while encompassing strength and safety. ... and it's wide! Australians and Americans have grown somewhat over the decades, many plane manufacturers just don't seem to have kept up with that fact. One unusual feature with Bob is the staggered cabin to give real world shoulder and arm room to the Pilot and Pax, no more of the upper body 'twist' to avoid rubbing shoulders with your smelly Buddy on the way to grab a hamburger, and somewhere to actually rest your arm. A further bonus is that the stagger is made up of just 4 components, the armrest, the rear fairing, a small filler panel behind your shoulder, and of course the canopy - all 3 components can be widened or narrowed to suit the owner with considerable ease, either during the build or modified later on. ... but it's also just plain wide. The inside is the magic 1 meter, or 39.5", and the shoulder room is over 1200mm or 48". As you have seen, I build what I show, the complete rear fuselage, VS and HS parts have all been cut and waiting for me to get there, and get them to the fold shop. Assembly should start in a few days! -

Look at the bright side, just think of how much lighter it will be after drilling all those holes!

-

Who? We miss the Drifter Mate. Bloody illegal immigrants, hope you flew them back!

-

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

Yup, have had the misfortune to have to remove 'old' plastic before that once you get the bulk of it off, you're left with lots of thumb sized bits you need to remove one by one picking at with your fingernails. Drives you crazy. -

No post for 3 weeks, you ok Franko?

-

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

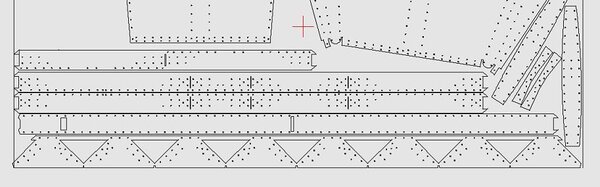

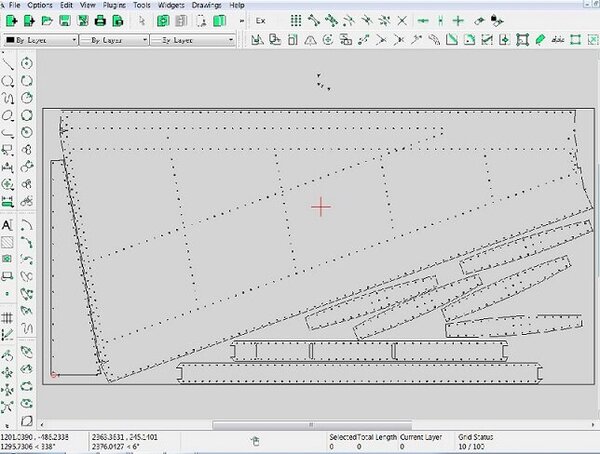

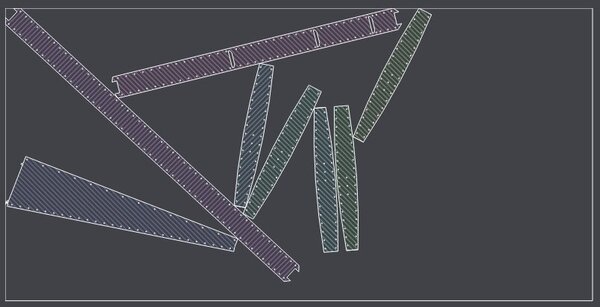

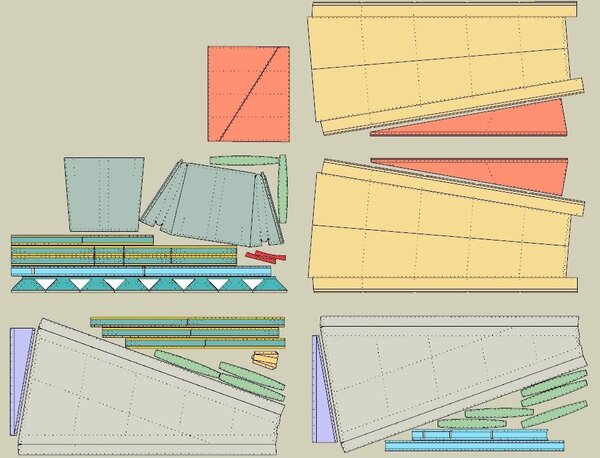

Here's maybe a helpful tip for those interested. You see the 4 long rectangular parts that compromise 13 separate parts end to end, and the 8 pyramids at the bottom (that just fit onto the sheet) to be lasered ... Well the reason they are joined like that instead of individual parts is for accuracy in the folding that they will receive later. Folds are done in a brake press and the longer the part, the less percentage of error over the length. So each long rectangle, and those 8 pyramids, will be folded together as one piece, then cut apart with the snips, and all the parts will be very close to being identical. Oh, and the pyramids (gussets) are flipped every 2nd one so i get left and right hand parts automatically after folding. -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

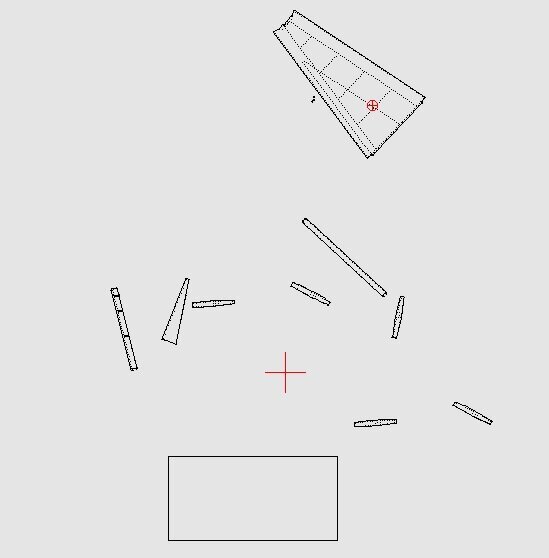

Almost saw sunrise this morning, but worth it because all CNC Laser files finished (for the rear fuselage stage), and 6 sheets dropped into the Laser shop with the file, should see some parts late tomorrow or Wednesday. My biggest headache today was getting the protective plastic film off the 6 sheets, damn they don't make life easy! I tried a free open-source one called Deepnest, let it run for a hour and it was just coming up with stupid results. My method is very simple, I put the biggest parts possible onto a sheet (importantly I design the parts so they can fit onto a 1200 x 2400 sheet in the first place), then try to fit the second biggest part on, if not, then the third biggest and so on. I can't understand why this stupid software doesn't do that and start with the biggest parts first? Here's mine..... .. what I gave to the software to test .. ... and it's best offering after an hour .. -

Well Ashley, Heinz slipped me a 20 to say something nice ...

-

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

-

Geez that's a nice build Marty, not every Zenith builder can get 0.016" looking that smooth.

-

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

Non-believer! Heresy, damnation for you!! I actually enjoy it, find the puzzle solving a bit of fun. Strange, because I have always disliked jigsaw puzzles. However, I haven't looked for a few years and noticed a couple of free ones out there, so going to try them and see if they can do better than what I already have. -

I just noticed this. Well explained except that hightlite the parts you want to create an intersection, then highlite the individual parts, 'Group' them and remove to one side from the assembly. i.e. don't group them first. You will find sometimes it won't cut a pre-group'd part. If you like, you can then right click on a group, 'make component', right click again and 'save' to a separate folder. If you want an assembly saved like that, group all the assembly groups together as one first, then make component, then save, just easier. My favorite unwrap tool is 'Flattery', it gets you everywhere!

-

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

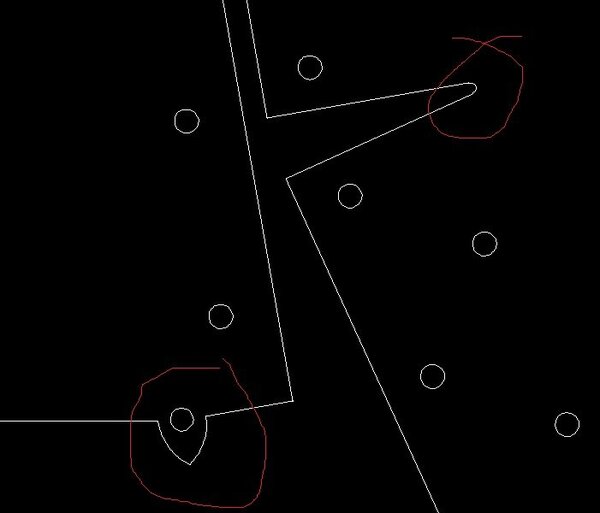

My bend radius is around 4T so grain isn't an issue. All my sheets have alignment tits or other for the bend shop to line up, saves a lot of time and is very accurate, as indicated in red below Later when my tits are cut off (wait, what?), a relief corner radius is left, as is in the corner of the inverted V bend point. -

W10 Tailwind EFATO accident • NZ (video)

bexrbetter replied to Garfly's topic in Aircraft Incidents and Accidents

Been used since I was a teenager (late 1970's), and used by our girlfreinds in our social group. We at first critisised them for the 'American' term. -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

Oh, and have a name for the plane at the moment. It was a tough one, but I took in the considerations of my Sino -Australia relationship and America being the key market, the plane type, specs, mission suitable for ect and eventually I came up with the perfect fit ... "Bob". . -

The XPB Stage 1 underway.

bexrbetter replied to bexrbetter's topic in Aircraft Building and Design Discussion

Man, been putting some hours in, seen sunrise a couple of times. I nested the entire Rear Fuse, HS and VS, then I virtually built the entire assembly again in the software to find the small fitting issues, and there were some, mostly rivet holes not lining up, couple of part sizes not change or moved (or not) at some stages.. And when I say build, starting with flat sheets as if they had just been cut. I folded and fitted them all together piece by piece then modified them if required, transposed to flat sheet, fold again and repeat. There's also the one that used to catch me out a few times years back, and that's creating stuff in 3D as flat material not allowing for the thickness of the material in the real world, and over a few parts, that error can build up quite quickly. So now tonight I celebrate my first sheet of 6 for the in .DXF file ready to go to the laser and fold shop early next week. I tried hard to fit everything onto 5 sheets, but just couldn't, dang narn it!