skippydiesel

Members-

Posts

7,504 -

Joined

-

Last visited

-

Days Won

72

Information

-

Aircraft

ATEC Zephyr, Sonex Legacy (A)

-

Location

The Oaks

-

Country

Australia

Recent Profile Visitors

17,649 profile views

skippydiesel's Achievements

Well-known member (3/3)

-

Hi BurnieM, "That is pretty disappointing 18-20 amps for a 912 ULS. But still should probably be 'enough'." Yes it is more than enough for a basic day VFR aircraft. The two 912 ULS powered aircraft, I have owned, never had a shortage of charging amps (assuming VR working correctly). I do make a point of having ancillary navigation device (iPad/GPS/SE2 & any other systems) fully charged before flight. My simple thinking - reduces demand from charge system and heating of individual devices, reducing chance of going out on over temp. As a rule of thumb - its best to fly/drive for at least 30 + minutes, to give the charge system enough time to make good any losses due to starting. If you start adding lights and extra electrically driven systems (eg autopilot/flaps/trim/seat/retractable undercarriage/constant speed prop) you may want more. This is when the option for a second alternator comes in.😈

-

Designated Remote Areas, Au

skippydiesel replied to skippydiesel's topic in AUS/NZ General Discussion

I am concerned about ".......I’m yet to work out the Sportstar’s range." Range is a factor of fuel available, fuel consumed/hr, at a given ground speed. Ground speed is affected by wind speed & direction ie faster & further with a following wind/slower & shorter with a head wind. The short message is - work on knowing your fuel consumed/hr, at your preferred Cruise speed. Your Take-off , Climb & Descent to landing are your short duration exteem consumptions. Cruise is where you spend most of your time/fuel consumed on a trip. I prefer to know my average fuel consumption/hr for the whole trip, rather than fuel consumed at Cruise itself. This will include Take-off, Climb, Cruise & Descent to Landing. If using OzRunways, it will ask for Taxi, TO, Climb, Cruise, Descent , fuel consumption - put in figures that are most likly to give a conservative result (POH/Rotax Operators manual will help with this). Keep a fuel log - Flight time (I use Hobbs) and Litres to refuel to same point (easy just to completely fill) = L/hr used for last flight. I then add a conservative extra eg known to deliver 14L/hr & 100 knots, flight plan at 15 or 16L/hr . Remember higher power settings = more fuel used for a faster air speed and the converse. Try & figure out what you prefer to do and stick to that power/prop pitch setting for all long distance flights. Plug your planed fuel consumption/hr into your calculations - this will tell you if you will make your destination or have to stop for fuel at one or more waypoints. Your range will vary for every given leg of every trip and will hardly ever be exactly as planned. Try never to use your reserve (mine is 30L = two hrs = 260 Nm in still air ) Be Safe! 😈 -

"Can somebody tell me how much charge I get from the 912 ULS alternator?" https://www.rotax-owner.com/en/912-914-technical-questions/10084-what-is-the-net-output-of-rotax-s-internal-generator_1 There is something not quite right about your charging system😈

-

There are "crush washers" and then there are other washers; The crush washers supplied by Rotax are really one use items (very thin formed/folded copper)- at a pinch may do a second period. Soft thick, aluminium, copper, washers can be used almost indefinitely, with care (as you suggest). Thick plastic/neoprene types, can also be used many times, with similar care but doubt you will get the X uses that the above may deliver. Rubber - with extreme care (very low tightening/torque) may give weep free service, once if you are lucky. The old style thick aluminium, copper, plastic, are not see easy to find these days, in the the automotive stores😈

-

-

Moneybox - check this out SB-912-079.pdf 😈 PS Your aircrafts POH should have the prop/engine inflight adjustment operating instructions.

-

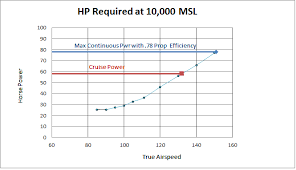

"When I'm cruising I have to adjust my propeller to a high pitch to prevent the engine running over maximum revs. " Small but important point to avoid any confusions - Propeller pitch is expressed as Coarse to Fine. Terms relative to the angle of attack (like a wing) to the airflow. What you seem to have described is Corsening the pitch to slow the engine rpm at a given power setting. "What I don't understand is where my best/least fuel consumption comes from when matching RPM to Manifold Pressure while maintaining cruising speed." In my aircraft (912ULS/Constant Speed prop) best speed/economy is in the region of 5000 - 5200 rpm. I usually Cruise at 5000 rpm, 25" Hg , 2500 ft ASL for a an average (whole of flight)fuel flow of about 14.25L/hr @ 130 knots true. Your aircraft will deliver a diffrent True airspeed at similar settings. "Lets say I want to keep the Rotax 912ULS spinning at 5000 revs while getting my best economical cruise speed. Do I control this with manifold pressure?" Manifold pressure will change with density altitude. With an acurate graph/power chart for your aircraft/engine/prop combination, you can adjust power accordingly. I find the following easier; On my last aircraft I had a reasonably accurate fuel flow meter, so was able to adjust power at any altitude to fuel flow. My current aircrafts fuel flow meter is nowhere near as precise, so I fly to True airspeed - probably offends the real pilots but works for me.😈

-

skippydiesel started following Oil filter cutter. , Manifold Pressure , Rotax 912 oil tank crush washer. and 1 other

-

Rotax do publish the manifold pressure/expected fuel flow/ altitude/ engine rpm charts; Join Rotax Owners Forum for all the Manuals/Service letters/etc https://www.rotax-owner.com/en/rotax-forum I strongly advise you read the Rotax 912 ULS Operators Manual file:///C:/Users/User/Downloads/OM_912%20Series_Ed4_Rev2%20(3).pdf Some downloads that may interest you; https://legacy.rotaxowner.com/si_tb_info/serviceletter/sl-912-016-r1.pdf https://aquila-aviation.de/wp-content/uploads/2021/06/SL_912_016R2_914_014R2_Rotax_Notes_engine_handling.pdf A couple of excerpts; Note: The figures given are nominal ie will differ due to many factors eg airframe😈

-

It should be a "copper crush washer". Yes any correctly sized sump style washer, can be substitutes eg soft aluminium, solid copper, neoprene, etc. The above washers can be purchase from almost any auto accessory supply store. I purchased my "stash" from Floods at the same time that I purchased oil filters. I get x3 washers to filters, as I use the same crush washer on the magnet and I practise 50 hr oil changes, filter at 100 hrs.😈

-

Constant Speed Prop Dynamic Balance

skippydiesel replied to skippydiesel's topic in Engines and Props

"........ this likely because you are capturing this data on the ground. Because rotary wing aerodynamics. If you set cruise pitch/RPM setting on the ground, sitting statically, the angle of attack on the blade would be far higher than in fine pitch, something it would not be encountering in flight because of the big differences in induced flow velocity (thence the resultant relative wind), therefore the data would not be representative. The angle of attack for your prop blade running at fine pitch on the ground is likely not too far removed from what it would be in flight at your cruise RPM/pitch. This is why the prop pitch setting is minimal on the ground and in takeoff and is advanced for your in-flight regimes (ie climbout, cruise, descent)- so it is operating at its design factor of merit (your prop efficiency) as much as possible...and also the most likely explanation as to why they want flat pitch on the ground. If you were doing this in flight, then there would be an appropriate regime for this to capture the data...in your case, the OEM specified pitch & RPM setting for a given airspeed & pressure altitude. This video explains, visually, what I am talking about:" -

Designated Remote Areas, Au

skippydiesel replied to skippydiesel's topic in AUS/NZ General Discussion

Well I aspire to fly across the Nation, Sydney - Perth/return, at least once. Further afield if that test flight workes out. I got out of GA because I couldn't fill a four seater, let alone a 6. All of your nominated airfields will be visited, plus many others, with a flight plan of 15L/hr ULP @ 130 knots true. 😈 -

Constant Speed Prop Dynamic Balance

skippydiesel replied to skippydiesel's topic in Engines and Props

So far I have taken the following from the responses to this question; Prop manufacturer sees no reason for not analysing vibration at Cruise rpm & Cruise pitch. Doing a vibration test in the air, may result in a better vibration analysis. I do not think I am any the wiser, as to why the prop manufacturer specifies having the prop at Fine Pitch, for this test. 😈 -

What about using a paint cone filter?😈

-

For out technical Forum 😈 https://www.google.com/search?q="Turbo+Encabulator"&rlz=1C1GGRV_enAU751AU751&oq="Turbo+Encabulator"+&gs_lcrp=EgZjaHJvbWUyBggAEEUYOTIHCAEQABiABDIHCAIQABiABDIHCAMQABiABDIHCAQQABiABDIHCAUQABiABDIHCAYQABiABDIHCAcQABiABDIHCAgQABiABDIHCAkQABiABNIBCTMzMjJqMGoxNagCCLACAfEFTZ_cH81_qsjxBU2f3B_Nf6rI&sourceid=chrome&ie=UTF-8#fpstate=ive&vld=cid:85f99d6b,vid:Ac7G7xOG2Ag,st:0

-

I'm amazed, all you guys with your cheepo, non aircarft certified, oil filter can cutter haven't YET been attacked by the aircraft certified, lest you fall out of the sky, only way to go, chaps.😈